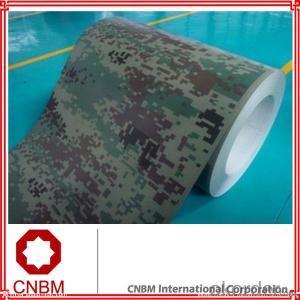

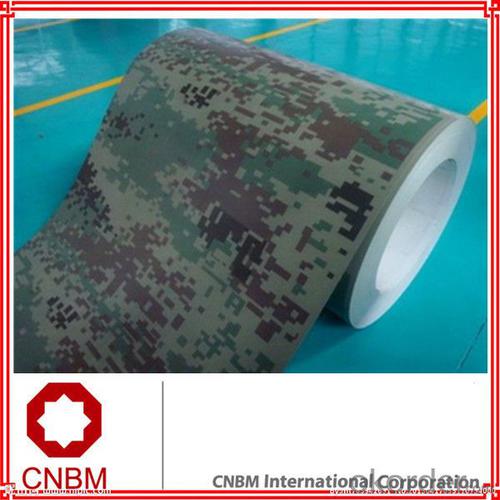

Prepainted cold rolled steel coil construction building material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 23453 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

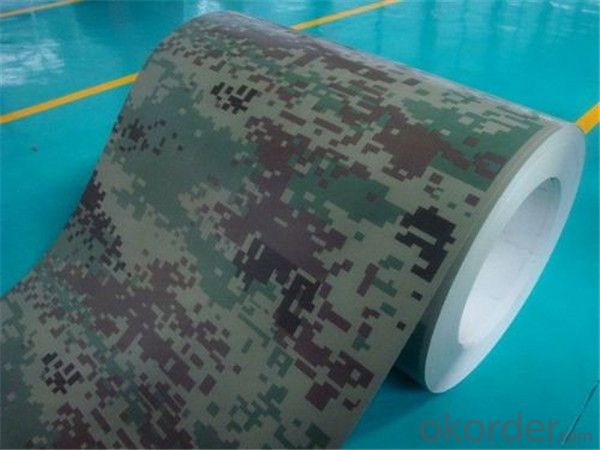

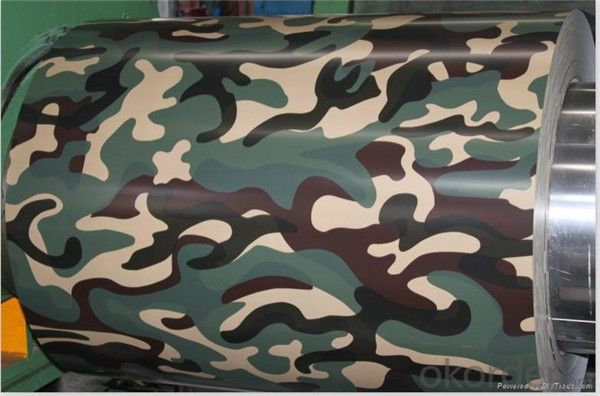

Prepainted cold rolled steel coil construction building material

Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

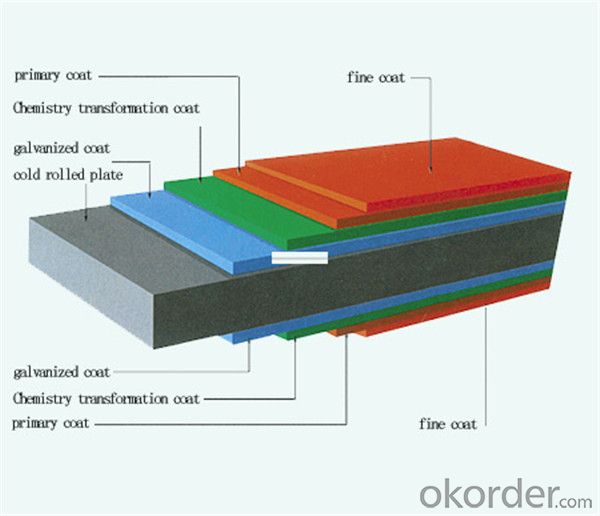

The production process has evolved from one-coating-and-one-baking to double-coating-and-sigle-baking,double-coating

-and-double-baking and even three-coating-and-three-baking

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

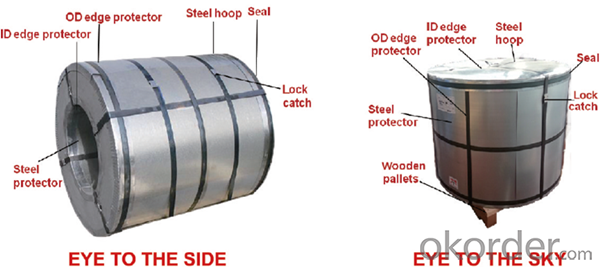

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our service

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include high corrosion resistance, durability, and a shiny, metallic appearance. Galvanized steel coils are coated with a layer of zinc, which acts as a protective barrier against rust and other environmental factors. This coating also enhances the strength and longevity of the steel, making it suitable for various construction and manufacturing applications. Additionally, galvanized steel coils have excellent formability, allowing them to be easily shaped and fabricated into different products.

- Q: 3 bedroom rambler with attached garage. A bad hail storm in May damaged my white siding and roof. I am concerned insurance adjustThanks much.er will not give me replacement value for steel siding. Any one know the cost and where to buy in Minnesota.

- In answer to you vinyl vs. steel siding. The differences are dramatic. Vinyl has the tendency to sag for two reasons; 1. Poor install, 2. Poor quality of the siding. I am a strong advocate of steel siding and seamless steel in particular. I am familiar with steel siding jobs that have been installed over 15-20 years. A high quality steel siding only needs to be rinsed or washed every few years to maintain its original look. Steel may cost more up front but it will pay back in spades for years to come.

- Q: i have a guitar with three nylon three steel strings. Am i able to replace the nylons with steel strings?

- Depends okorder Classical guitars aren't able to handle the tension of steel strings for the most part. Be careful with deciding which type and gauge string to put on certain guitars.

- Q: What are the challenges faced in the recycling of steel coils?

- The recycling of steel coils presents several challenges that must be overcome. To start, the collection and sorting process poses a significant hurdle. Steel coils are often utilized in large-scale industries and construction projects, making it challenging to gather and transport them for recycling purposes. Moreover, steel coils can become mixed with other materials, such as plastic or wood, further complicating the sorting process. Another obstacle is the size and weight of steel coils. Given that steel is a heavy material, handling and processing large coils can be quite difficult. Specialized equipment and machinery may be necessary to efficiently move and separate the coils, thereby increasing the cost and complexity of the recycling process. Additionally, the recyclability of steel coils can be impacted by varying quality. These coils may contain impurities or contaminants, such as oil or paint, that must be eliminated before recycling. Such impurities can compromise the integrity and quality of the recycled steel, making it less desirable for certain applications. Moreover, the recycling of steel coils demands substantial energy and resources. Melting down the steel requires a significant amount of energy, while the transportation and processing of the coils also consume resources and contribute to carbon emissions. Consequently, the environmental friendliness of the recycling process can be diminished. Lastly, the viability of the recycling industry can be influenced by fluctuating market demand for recycled steel coils. The demand for steel products can vary depending on economic conditions and industry trends, making it challenging for recyclers to find buyers for their recycled coils. This can potentially result in stockpiling or disposal difficulties. In conclusion, while recycling steel coils offers environmental benefits and resource conservation, several challenges must be addressed for its successful implementation. These challenges encompass collection and sorting, handling and processing, quality control, energy and resource consumption, as well as market demand.

- Q: How are steel coils used in the production of power generation equipment?

- Steel coils are used in the production of power generation equipment as they are shaped and formed into various components such as turbine casings, generator frames, and steam pipes. These coils provide the necessary strength and durability to withstand the high temperatures, pressure, and mechanical stresses involved in power generation processes. Additionally, steel coils are often coated with protective layers to prevent corrosion, ensuring the longevity and reliability of the equipment.

- Q: What are the common storage defects in steel coils?

- Some common storage defects in steel coils include: 1. Staining or discoloration: If steel coils are not stored properly, they can be exposed to moisture or chemicals, leading to staining or discoloration. This can affect the appearance and quality of the steel. 2. Rust or corrosion: Steel is susceptible to rust and corrosion if it comes into contact with moisture or is stored in a humid environment. Rust can weaken the steel and compromise its integrity. 3. Coil deformation: Improper stacking or handling of steel coils can result in deformation or bending. This can occur when coils are stored on an uneven surface or subjected to excessive pressure or weight. 4. Surface damage: Steel coils can develop surface scratches, dents, or abrasions if they are mishandled during storage. This can be caused by improper stacking, handling, or transport of the coils. 5. Edge damage: If steel coils are not properly protected or secured during storage, the edges can become damaged. This can include chipping, cracking, or bending of the edges. Edge damage can affect the usability and safety of the steel coils. 6. Coil slippage: When steel coils are not securely stored or stacked, they can slip or roll off, causing damage to the coils themselves and potentially causing harm to nearby personnel or equipment. 7. Contamination: Steel coils can become contaminated if they are stored near or come into contact with substances such as dirt, oil, grease, or chemicals. Contaminants can affect the quality and performance of the steel. 8. Coil nesting: Inadequate spacing or stacking of steel coils can result in coil nesting, where one coil becomes embedded or nested within another. This can lead to damage to the coils, making them difficult to separate and use. To prevent these common storage defects, proper handling, storage, and protection measures should be implemented. This includes storing steel coils in a dry, well-ventilated area away from moisture and chemicals, using appropriate stacking and support structures, and providing adequate protection against impacts and contaminants. Regular inspections and maintenance should also be conducted to identify and address any potential defects or issues.

- Q: What are the different methods of coil packaging for steel coils?

- There are several different methods of coil packaging for steel coils, each with its own advantages and suitability for specific applications. Some of the common methods include: 1. Strapping: This method involves using steel or plastic strapping to secure the coil and prevent it from unwinding or shifting during transportation. Strapping can be done manually or with the help of strapping machines, offering a cost-effective and reliable packaging solution. 2. Stretch wrapping: Stretch wrapping involves using a stretch film to tightly wrap the coil. The film is stretched and wrapped around the coil, providing protection against dust, moisture, and damage. This method is suitable for lightweight coils and offers good visibility of the product. 3. Steel banding: Steel banding is a robust and heavy-duty packaging method that involves using steel bands to secure the coil. This method provides high strength and durability, ensuring that the coil remains intact during transportation or storage. 4. Edge protectors: Edge protectors are used in conjunction with other packaging methods to safeguard the edges of the coil. These protectors are typically made of cardboard or plastic and provide additional support to prevent edge damage. 5. Wooden crates: For heavy or fragile steel coils, wooden crates are often used to provide maximum protection. The coils are placed inside the crate and secured with strapping or steel banding. Wooden crates offer excellent strength and stability and can be customized to fit specific coil dimensions. 6. Paper interleaving: This method involves inserting layers of paper or cardboard between individual wraps of the coil to prevent scratching or marking. Paper interleaving is commonly used when the coils are stacked together or when they have a high surface finish that needs to be protected. 7. Automated packaging systems: In larger-scale operations, automated packaging systems can be utilized. These systems are designed to handle and package coils using various methods, such as strapping, stretch wrapping, or steel banding. They offer increased efficiency and productivity while ensuring consistent and secure packaging. The choice of coil packaging method depends on factors such as the size and weight of the coil, transportation requirements, level of protection needed, and cost considerations. It is essential to select the appropriate packaging method to ensure the safe delivery of steel coils to their destination.

- Q: I like non-stick cookware but it dont hold up no matter how much money you spend. What isthe best kind? Is there something better then stainless steel or iron skillet? I do not care if I have to use extra elbow grease to clean a pan.

- Some utensils are both cookware and bakeware. The choice of material for cookware and bakeware items has a significant effect on the item's performance , particularly in terms of thermal conductivity and how much food sticks to the item when in use. Some choices of material also require special pre-preparation of the surface - known as seasoning - before they are used for food preparation. Stainless steel cookware is a great choice for safe cooking. Many kinds of cookware react with the foods, either changing the taste of the food or even releasing harmful materials into the food that can cause imbalances or diseases. Many non-stick coatings like teflon are safe - but once they get scratched or overheated they can start to leak chemicals in the food that are according to some scientific studies dangerous and possibly carcinogenic. Both the cooking pot and lid handles can be made of the same material, but will mean that when picking up or touching either of these parts oven gloves will need to be worn. In order to avoid this, handles can be made of non heat conducting materials, for example bakelite, plastic or wood. It is best to avoid hollow handles because they are difficult to clean or to dry.

- Q: What are the weight ranges for steel coils?

- The weight ranges for steel coils can vary depending on the specific type and thickness of the steel. However, common weight ranges for steel coils typically range from a few hundred pounds to several thousand pounds.

- Q: What is the material of steel coil 08F and what brand can be used instead?

- Characteristics and applicable range of 08F:Its strength is low, and the steel is soft, plastic and tough. General use does not require heat treatment, but in order to eliminate the internal force due to cold processing, improve the cutting performance of steel, heat treatment can be carried out, cold processing can increase the intensity. Often used in the manufacture of stamping parts and carburizing parts, such as stamping products, sockets, enamel products, automobile shell, etc..

Send your message to us

Prepainted cold rolled steel coil construction building material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 23453 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords