Prepainted Steel Coil PPGI GI of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

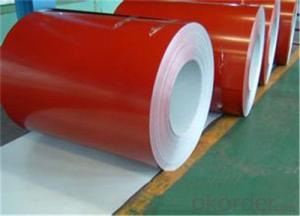

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Thickness: | 0.12 - 2.00 mm | Place of Origin: | Tianjin China (Mainland) |

| Brand Name: | cnbm | Model Number: | DX51D ,SGCC,SGCH | Type: | Steel Coil |

| Technique: | Hot Rolled | Surface Treatment: | Galvanized | Application: | Construction |

| Special Use: | High-strength Steel Plate | Width: | 702mm- 1250mm | Length: | as your requirement |

| Certification: | BV,SGS,TUV |

Packaging & Delivery

| Packaging Detail: | standard sea-worthy package or as customers' requirement |

| Delivery Detail: | generally 10-25 days or as customers' quantity |

Specifications

1.reasonable price

2.reliable quality

3.fast shipment

4.huge production capacity

5.BV,SGS and TUV certificates

The details:

| Base Material | Hot Dipped Galvanized Steel |

| Grade | ASTM,DX51D,SGCC,CGCC and CGCH. |

| Thickness | 0.12~2.0mm |

| Coil width | 600~1250mm |

| Coil ID | 508- 610mm |

| Coil weight | 3~7 tons |

| Zinc coating | 40~275 g/m2 |

| Painting | Top and bottom :15~25 microns |

| Back :5~8 microns | |

| Color | RAL system as per customers requirement |

| Package | Export seaworthy packing |

| MOQ | 25 tons |

- Q: What is the difference between a steel sheet and a steel plate?

- The differences between a steel sheet and a steel plate are significant. Firstly, the thickness of a steel sheet is typically less than 6mm, whereas a steel plate is generally thicker, measuring 6mm or more. This discrepancy in thickness is primarily attributed to the intended purpose of each product. Steel sheets are commonly used in scenarios where weight and flexibility are crucial, such as in the production of automobile bodies or appliances. Conversely, steel plates are frequently employed in heavy-duty constructions such as bridges, buildings, or machinery, where strength and durability are of utmost importance. Another distinction can be found in the manufacturing process. Steel sheets are usually created through hot rolling, which involves heating the steel above its recrystallization temperature and subsequently passing it between rollers to achieve the desired thickness. On the other hand, steel plates can be made through either hot rolling or cold rolling processes. Cold rolling entails passing the steel through rollers at room temperature, resulting in a more precise and smoother surface finish. Furthermore, the size of steel sheets and plates also differs. Steel sheets are often standardized in terms of width and length, making them more manageable and easier to transport. In contrast, steel plates are available in various sizes and dimensions, providing greater customization options to suit specific project requirements. To summarize, the key distinctions between a steel sheet and a steel plate lie in their thickness, manufacturing process, and intended use. Steel sheets are thinner and lighter, while steel plates are thicker and utilized in heavy-duty applications that demand strength and durability.

- Q: What is the difference between hot dipped galvanized and electro galvanized steel sheets?

- The main difference between hot dipped galvanized and electro galvanized steel sheets lies in the process of coating. Hot-dipped galvanized steel sheets are coated by immersing them in a bath of molten zinc, which creates a thicker and more durable layer of zinc compared to electro galvanized steel sheets. On the other hand, electro galvanized steel sheets are coated by an electrolytic process, where a thin layer of zinc is applied to the steel surface. This makes electro galvanized steel sheets more suitable for applications that require a thinner coating and a smoother finish, while hot-dipped galvanized steel sheets provide excellent corrosion resistance and are often used in more heavy-duty applications.

- Q: Can steel sheets be used for manufacturing machinery parts?

- Yes, steel sheets can be used for manufacturing machinery parts. Steel is a strong and durable material that is commonly used in the manufacturing industry for various applications, including machinery parts. Steel sheets can be easily formed, cut, and welded to create complex shapes and structures required for machinery components. Additionally, steel offers excellent mechanical properties such as high tensile strength and resistance to wear, which are crucial for machinery parts that are subjected to heavy loads and frequent use.

- Q: Can steel sheets be used for roofing purposes?

- Yes, steel sheets can be used for roofing purposes. Steel roofing sheets are commonly used in commercial and industrial buildings, as well as residential homes. They are known for their durability, longevity, and resistance to harsh weather conditions such as rain, snow, and wind. Steel sheets are available in various profiles and finishes, allowing for customization to suit different architectural styles and design preferences. Additionally, steel roofing is lightweight, fire-resistant, and often made from recycled materials, making it an environmentally friendly roofing option. Overall, steel sheets are a popular choice for roofing due to their strength, versatility, and aesthetic appeal.

- Q: Can steel sheets be used for structural purposes?

- Yes, steel sheets can be used for structural purposes. Steel sheets are commonly used in construction and engineering projects to provide strength and support to various structures such as buildings, bridges, and infrastructure. The high tensile strength and durability of steel make it an ideal material for structural applications.

- Q: Can steel sheets be used for automotive manufacturing?

- Certainly, steel sheets have the ability to be employed in automotive production. The automotive sector extensively utilizes steel due to its robustness, longevity, and cost efficiency. Steel sheets find common application in diverse automotive constituents like body panels, chassis, frames, and structural reinforcements. They offer the essential strength and stiffness necessary to ensure the safety and functionality of vehicles. Furthermore, steel sheets can be effortlessly shaped and molded into various forms, rendering them appropriate for intricate automotive designs. Additionally, steel is easily obtainable, hence making it a favored option for automotive manufacturers.

- Q: How thick are steel sheets typically?

- Steel sheets can vary in thickness depending on their intended use, but they are typically available in thicknesses ranging from 0.5mm to 6mm for general applications.

- Q: Can steel sheets be used for solar panel installations?

- Solar panel installations can indeed utilize steel sheets. With their strength and durability, steel serves as a reliable foundation for mounting solar panels. Notably, steel sheets are frequently employed in the construction of support structures like mounting frames or racks for solar panels. Their malleability allows for easy shaping and cutting to meet installation requirements. Moreover, steel's resistance to corrosion is essential for prolonged outdoor usage. Nonetheless, it is vital to ensure appropriate insulation and grounding to avert potential electrical problems associated with employing steel sheets for solar panel installations.

- Q: Can steel sheets be used for storage containers?

- Yes, steel sheets can be used for storage containers. Steel is a strong and durable material that can withstand heavy loads and harsh weather conditions, making it ideal for storage containers. It offers excellent protection against moisture, pests, and theft. Steel containers are commonly used in various industries such as shipping, construction, and warehousing. They are also popular for temporary storage solutions and can be easily transported and stacked. Additionally, steel containers can be customized with various accessories such as doors, windows, and ventilation systems to suit specific storage needs.

- Q: What are the functions and classifications of galvanized sheet?

- Transportation industry: car, car, car shell ceiling board, tractor, tram, container, highway fence, ship bulkhead etc.Other instruments shell, trash, billboards, watches, photographic equipment, measuring devices and other color coated steel plate with hot galvanized plate, hot galvanized plate, galvanized plate as the substrate, the surface of galvanized plate type pre processing include: hot galvanized plate, galvanized plate, tinplate, galvanized plate pressing and molding, with connecting hooks, without any accessories can be securely firmly connected mesh columns.Galvanized sheet according to its use can be divided into: activated alumina, galvanized plate, desiccant, galvanized plate and catalyst galvanized sheet. The inner cavity of the working room is made of high quality galvanized or stainless steel plate to make it rustproof and clean;

Send your message to us

Prepainted Steel Coil PPGI GI of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords