Prepainted Galvanized Steel Plate/ PPGI/GI

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Details

Basic Info.

Type:Steel Plate

Standard:ASTM, GB, JIS

Certification:ISO, SGS

Surface Treatment:Coated

Technique:Cold Rolled

Application:Ship Plate

Special Use:High-strength Steel Plate

Stock:Stock

MOQ:25 Tons

Material:SGCC,Sgch.Full Hard/Soft

Spangle:Regular/Big/Small/Zero

Zn Coated:60-120G/M2

Width:760-1250 Mm

Length:Under 5 Meter

Bundle Weight:2-3 Tons

Export Markets:South America, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Packing:Seaworthy Standard Export Package

Standard:SGS, ISO9001

Origin:Boxing County, Shandong Province

HS Code:72107010

Production Capacity:60000 Tons/Year

Product Description

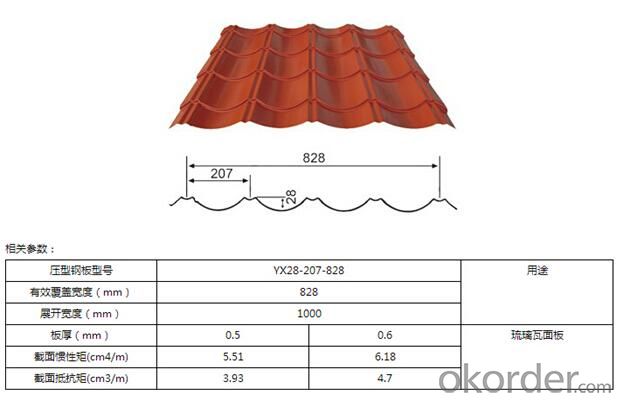

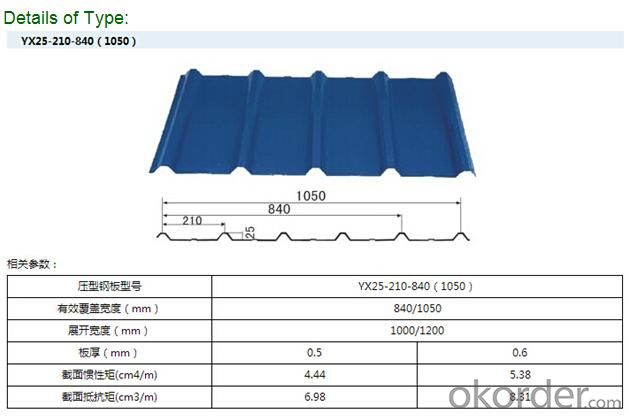

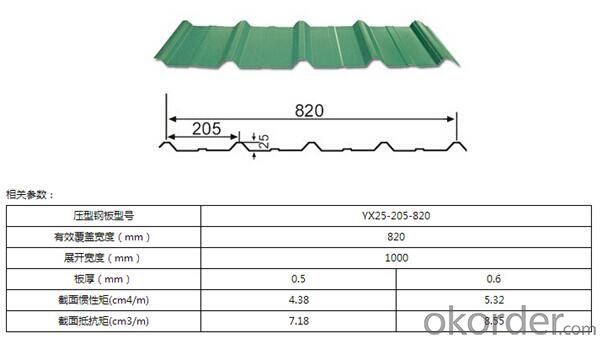

corrugation of hdgi for roofing :

| With the professional produce line, we can manufacture the best quality with competitive price as below: | |

| Thickness: | 0.18-0.80 mm |

| Sheet Width: | 760-1075 mm |

| Bundle weight: | 2.0-3.0 MT |

| Surface finish : | 60-120g/m2 zinc coating and the customers requirment! |

| Type: | YX28-207-828, YX14-63.5-850, YX15-225-900, YX35-125-750 , YX76-380-760, YX12-110-880, YX10-130-910, YX25-205-820/1025, YX25-210-840/1050, YX20-215-860/1075. |

| Standard: | JIS G3302, JIS G3313, ASTM A653, GB/T2518-88, GB11253-89,ASTM A1008- 2000,BS,ETC. |

| Packing: | wrapped by plastic film and waterproof paper, and then fastened on wooden pallet. Used in building material field,Pipe making, furniture making,others |

| MOQ: | 25 tons |

| Delivery times : | 20 days after received T/T or L/C |

| Payment terms : | T/T or L/C ( or as your demand) |

| Supply ability : | 6,000 ton per month |

| County we ever exported: Indonesia, Georgia, Mozambique, Somalia, Myanmar, Argentina,India,Dubai, and Turkmenistan. we can supply you the products you need with most competitive price and high quality. special size and standard can be accepted! | |

Details of Type:

FAQ:

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: What are the different coil packaging materials used for steel coils?

- The different coil packaging materials used for steel coils include steel strapping, plastic strapping, stretch wrap, and wooden crates.

- Q: How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers as they are rolled into sheets, which are then cut and welded to create the walls, roof, and floor of the container. The high strength and durability of steel coils ensure that the shipping containers can withstand the rigors of transportation, protecting the goods inside.

- Q: What are the typical lead times for ordering steel coils?

- Lead times for ordering steel coils can vary based on factors such as coil type, size, supplier capacity, and market conditions. On average, lead times range from a few weeks to several months. When it comes to standard-sized steel coils readily available in the market, lead times are generally shorter. This is because suppliers keep stock of these commonly used sizes to meet immediate customer demands. However, transportation and logistics can still impact lead times. For custom-made or non-standard steel coils, lead times tend to be longer due to additional processes like cutting, shaping, or coating. Production time can range from a few months to six months or more, depending on the complexity of specifications and supplier capabilities. External factors like market demand and raw material availability can also affect lead times. During high demand or supply chain disruptions, suppliers may need to adjust production schedules, leading to extended lead times. To determine accurate lead times, it is recommended to contact specific suppliers or manufacturers. They can provide the most up-to-date information based on your requirements and current market conditions.

- Q: I bought a damascus steel knife. It will be used for display. Nothing like hunting/skinning. If It is just sitting around, will it rust? (assuming that it isn't getting wet) Thanks for the help.

- From that point of view the strength or edge-holding ability means very little. Specifically, the bushcraft knife is pattern welded steel. True damascus or Wootz steel is something you'll only find in museums and private collections. they stopped making it several hundred years ago. Despite what many people have claimed, Wootz damascus was inferior to modern tool steels in every respect. It was a brittle, dirty material.

- Q: How are steel coils inspected for paint adhesion using adhesion testers?

- Paint adhesion on steel coils is systematically and rigorously inspected using adhesion testers. These testers are specifically designed devices for assessing the bond strength between the paint and the underlying steel surface. To begin the inspection process, representative samples are selected from the steel coils. These samples are typically cut into smaller sections to ensure they are free from defects or surface irregularities that could impact the adhesion test results. Once the samples are prepared, the adhesion testers are utilized to measure the force needed to detach the paint coating from the steel surface. The most commonly used adhesion tester is the cross-cut adhesion tester. It consists of a set of blades arranged in a grid pattern, which are employed to create cuts through the paint coating, forming a grid of squares or rectangles down to the steel surface. After the cuts are made, a specialized tape is applied to the grid area and pressed firmly onto the surface. The tape is then rapidly pulled off at a 90-degree angle to the surface, and the force required for the paint coating's removal from the steel is measured and recorded. The results of the adhesion test are evaluated based on predetermined standards or specifications. These standards typically define the minimum acceptable adhesion strength for the specific application or industry. If the measured adhesion strength falls below the specified threshold, it indicates poor paint adhesion, which could result in issues like paint delamination or corrosion. Along with the cross-cut adhesion tester, other adhesion testing methods may also be utilized, such as the pull-off adhesion tester. This method involves a hydraulic or mechanical device applying a tensile force to a small circular or dolly-shaped test area. The force required to pull off the dolly is measured and used to assess the paint adhesion. In summary, the use of adhesion testers ensures a thorough inspection of paint adhesion on steel coils. This process helps in early identification of potential adhesion issues, enabling appropriate remedial measures to be taken to ensure the durability and performance of the paint coating.

- Q: What are the different methods of welding steel coils?

- Steel coils can be welded using various methods, each with its own advantages and applications. The most commonly used methods for welding steel coils are: 1. Resistance Welding: By applying pressure and electric current, this method generates heat and joins the steel coils. It is ideal for high-speed production and can be categorized into spot welding, seam welding, and projection welding. 2. Arc Welding: This technique involves creating an electric arc between an electrode and the steel coils, resulting in intense heat and metal melting. Different arc welding techniques include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). 3. Laser Welding: Laser welding employs a highly focused laser beam to melt and join the steel coils precisely. It offers excellent control, high welding speeds, and minimal heat-affected zones, making it suitable for thin materials and complex designs. 4. Electron Beam Welding: This method uses a concentrated beam of high-velocity electrons to melt and fuse the steel coils. It is commonly used for welding stainless steel and other high-temperature alloys, providing deep penetration and minimal distortion. 5. Friction Stir Welding: By plunging a rotating tool with a pin into the steel coils, heat is generated through friction, and the softened material is stirred together to form a solid joint. Although primarily used for joining aluminum, it can also be applied to steel coils. 6. Ultrasonic Welding: This technique involves applying high-frequency vibrations to the steel coils, creating friction and heat for fusing the materials. It is commonly used for smaller steel coils and provides fast and efficient welding with minimal distortion. These methods offer distinct advantages and are suitable for specific applications. The choice of welding method depends on factors such as the type and thickness of the steel, desired strength and quality of the weld, production speed, and cost considerations.

- Q: My boyfriend says he has balls of steel.

- Easy to test. Put a magnet near them. If they attract, then they're made of steel. I'd be willing to bet I'd know what will happen, though! I know you can get metal hip replacements but .........

- Q: How do steel coil manufacturers handle international shipping requirements?

- Steel coil manufacturers typically handle international shipping requirements by following a well-defined process. First, they ensure proper packaging and securing of the coils to prevent damage during transportation. This may involve using specialized equipment, such as coil racks or crates. Next, they comply with international shipping regulations and obtain necessary documentation, such as bills of lading and customs clearance forms. They coordinate with freight forwarders or shipping agents to arrange transportation and select the most suitable shipping method, whether it's by sea, air, or land. Throughout the process, manufacturers closely track shipments and communicate with customers to ensure smooth delivery and address any issues that may arise.

- Q: How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials by being unwound and flattened to create the wire used for fencing. The steel wire is then further processed and shaped into different forms, such as chain link or barbed wire, to meet specific fencing needs.

- Q: How are steel coils inspected for quality control purposes?

- Steel coils are inspected for quality control purposes through various methods such as visual inspection, dimensional checks, and non-destructive testing techniques. Visual inspection involves examining the surface of the coil for any defects or irregularities. Dimensional checks are conducted to ensure that the coil meets the specified thickness, width, and length requirements. Non-destructive testing techniques like ultrasonic testing or magnetic particle inspection are used to detect internal flaws or defects in the steel coil. These inspection methods help ensure that the steel coils meet the desired quality standards before they are used in various applications.

Send your message to us

Prepainted Galvanized Steel Plate/ PPGI/GI

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords