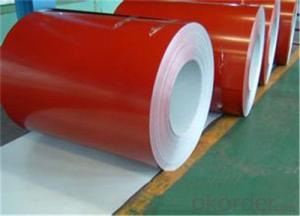

Prepainted Galvanized Steel Coil/ PPGI of CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,BS,GB,JIS,GB/T 13912-2002 | Grade: | CGCC | Thickness: | 0.15-0.8mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | cnbm | Type: | Steel Plate |

| Technique: | Hot Rolled | Surface Treatment: | Galvanized | Application: | construction industry; automobile making |

| Special Use: | High-strength Steel Plate | Width: | 0.15-0.8mm | Length: | On Request |

| Color: | On Request | Certificate: | ISO9001TUV | Zinc Coating: | Z60-Z150 or on request |

| Payment: | L/C T/T | Usage: | Buldings | Package: | Standard Export Packing |

| Type of Company: | Manufacturer | MOQ: | 25 Tons | Coil weight: | 3-8MT |

Packaging & Delivery

| Packaging Detail: | Standard Export Packing for the goods pallet packing or according to customer's request |

| Delivery Detail: | within 15-45 days after the receipt of L/C or deposit |

Specifications

Thickness: 0.15-0.8mm

Width: 700-1250mm

Length: On Request

Product Description

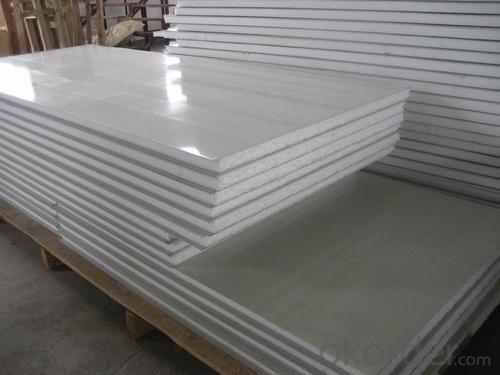

Prepainted Galvanised Steel Sheet

Brand Name: CNBM

Thickness: 0.15-0.8mm

Width: 700-1250mm

Length: As your request

Zinc Coating: 60-150g/ m² or as your request

Advantage:

| HIGH QUALITY |

| LOW PRICE |

| FAST DELIVERY |

Application:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

- Q: Why can steel HPB300, steel plate without Q300, steel structure manuscript review, but also continued the Q235, why not improve it?

- HPB's full name is hot rolled round steel (HPB is Hot-rolled Plain Steel Bar) in English, commonly known as wire rod, diameter 6 - 12 rounds of the most common, including HPB235 and HPB300. You haven't met HPB400?. HRB400 and RRB400 are treated steel bars in order to have such high strength. But the general strength, ductility will be reduced, as the saying goes, "tossing" is not resistant to toss about.

- Q: Are steel sheets available in textured finishes?

- Yes, steel sheets are available in textured finishes. Textured finishes can be achieved through various processes such as embossing, etching, or brushing. These techniques create patterns or textures on the surface of the steel sheet, giving it a unique and visually appealing appearance. These textured finishes not only enhance the aesthetic appeal of the steel sheet but also provide functional benefits like improved grip, reduced glare, or increased durability. Different types of textures can be applied to steel sheets to suit different applications and design preferences.

- Q: Are steel sheets suitable for agricultural equipment?

- Yes, steel sheets are suitable for agricultural equipment. Steel is known for its strength, durability, and resistance to corrosion, making it an ideal material for agricultural machinery that needs to withstand harsh conditions and heavy use. Additionally, steel sheets can be easily shaped and welded to create custom designs for specific farming applications.

- Q: How do steel sheets perform in terms of earthquake resistance?

- Steel sheets are highly effective in enhancing earthquake resistance due to their high strength and flexibility. The flexibility of steel enables it to absorb and dissipate seismic energy, reducing the impact on the structure. Additionally, steel sheets can be designed and fabricated to withstand specific seismic loads, making them a preferred choice for earthquake-resistant construction.

- Q: Are the steel sheets resistant to chemical spills?

- Yes, steel sheets are generally resistant to chemical spills due to their inherent corrosion resistance properties.

- Q: How are steel sheets measured?

- Steel sheets are typically measured in terms of thickness (in gauge or millimeters) and size (length and width).

- Q: How are steel sheets protected during welding?

- Steel sheets are protected during welding through a process called shielding. Shielding is essential to prevent the steel sheets from being exposed to oxygen and other atmospheric contaminants that can cause oxidation and impurities in the weld. There are various methods used to shield the steel sheets during welding. One common method is to use a shielding gas, such as argon or carbon dioxide, which is directed at the welding area to create a protective atmosphere. This gas displaces the surrounding oxygen, preventing it from reacting with the heated metal and causing oxidation. In addition to shielding gas, another method commonly employed is the use of flux. Flux is a substance that is applied to the joint area of the steel sheets prior to welding. It acts as a protective barrier, creating a molten slag that covers the weld and shields it from the atmosphere. Flux can be in the form of a powder, paste, or even a wire that is fed continuously during welding. Furthermore, some welding techniques, such as submerged arc welding, utilize a combination of both shielding gas and flux to provide optimal protection to the steel sheets. This technique involves the use of a granular flux that is fed continuously along with the welding wire. The flux melts and forms a protective layer over the weld, while the shielding gas prevents atmospheric contamination. Overall, the protection of steel sheets during welding is vital to ensure the quality and integrity of the weld. Shielding methods, such as shielding gas and flux, create a protective environment that prevents oxidation, impurities, and other defects from forming in the weld, resulting in a strong and durable joint between the steel sheets.

- Q: Are steel sheets available in different grades of stainless steel?

- Different grades of stainless steel are available, providing a range of options for steel sheets. Stainless steel is a versatile material widely used in industries like construction, automotive, and manufacturing due to its corrosion resistance and durability. Stainless steel has several grades, each with unique properties and composition. The most common grades are 304, 316, 430, and 201, which vary in chemical composition, including the amount of chromium, nickel, and other alloying elements. The choice of grade depends on the specific application and desired characteristics of the steel sheet. For instance, grade 304 is commonly used for general purposes because of its excellent corrosion resistance and strength. On the other hand, grade 316 is often preferred in environments with high exposure to corrosive elements, such as marine applications. Steel sheets are available in different thicknesses, sizes, and finishes, making them suitable for various applications. Whether you require stainless steel sheets for architectural purposes, food processing equipment, or industrial machinery, there is a grade that can meet your requirements. To ensure you select the appropriate grade of stainless steel sheet, it is important to consult with a supplier or manufacturer. They can provide guidance based on factors like the intended use, environmental conditions, and budget constraints. Ultimately, the availability of different grades of stainless steel sheets ensures there is a suitable option for diverse applications.

- Q: What is the thickness of the water resisting steel plate of the electrical outlet?

- The water resisting steel plate of the electric door mainly meets the need of welding between the sleeve and the setting of the water stopping line.

- Q: Are steel sheets suitable for structural applications?

- Yes, steel sheets are suitable for structural applications. Steel sheets are known for their high strength, durability, and versatility, making them an ideal choice for various structural projects. They can be easily manipulated and fabricated into different shapes and sizes, allowing for flexibility in design. Additionally, steel sheets offer excellent load-bearing capacity, resistance to corrosion, and fire protection, making them a reliable and long-lasting option for structural applications.

Send your message to us

Prepainted Galvanized Steel Coil/ PPGI of CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords