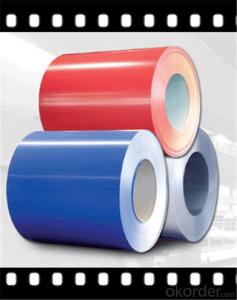

Hot sale Prepainted steel coil PPGI GI of CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,JIS | Grade: | steel | Thickness: | 0.25-0.8mm |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | CNBM | Model Number: | SGCC Q195L, Q235, DX51D |

| Type: | Steel Coil | Technique: | Hot Rolled,hot dip | Surface Treatment: | Coated |

| Application: | Flange Plate | Special Use: | Silicon Steel | Width: | 600-1250mm |

| Length: | 2000-6000mm |

Packaging & Delivery

| Packaging Detail: | seaworthy packing or as per buyer's requirment |

| Delivery Detail: | 10-20 days |

Specifications

1.reasonable price

2.reliable quality

3.fast shipment

4.huge production capacity

5.BV,SGS and TUV certificates

Prepainted Steel coil PPGI

Our Advantages

1. more than 10 years experiences in steel business

2. good quality

3. competitive price

4. meet your needs via reprocessing

5. excellent service

6. short delivery time

7. long mutual beneficial business cooperation

8. certificate: ISO9001

- Q: How are steel coils used in the production of packaging machinery?

- Steel coils are used in the production of packaging machinery as they serve as the raw material for manufacturing various components of the machinery, such as frames, supports, and structural elements. The steel coils are processed through cutting, bending, and welding to create the necessary parts, ensuring durability and stability in the packaging machinery's construction.

- Q: I was cutting a sheet of steel with an angle grinder when suddenly the rate at which the blade was cutting slowed way down. I tried a few different things, and turned off the tool and looked at the blade. It didn't look damaged, but it definitely was not cutting as quickly. I thought either I had hit a harder section of steel (is that possible? It looked pretty uniform) or the blade had lost it's abrasive quality or something. Also, before this happened I had accidentally cut into the wooden sawhorse that was holding up the steel sheet, but I've done that before with no problem. After a short while the problem fixed itself and the rate of cutting went back to a fast normal. Anyone know why this happened?

- Sounds like the abrasive surface got blinded, coated with something that prevented the abrasive particles from touching the steel. It is possible to have vastly different hardnesses in a single piece of steel. Case hardening, carburizing, induction hardening, heat affected zone from welding, differences in work hardening, and presence of inclusions are some of the things that can create hardness variation within a single piece. But... sounds like you are working with a sheet which is unlikely to have any of these conditions. So... it was probably the grinding disk

- Q: What is the average price of a steel coil?

- The average price of a steel coil can vary depending on several factors such as the type of steel, the thickness and width of the coil, the market demand, and the location of purchase. Generally, the price can range from $500 to $1500 per metric ton. However, it is important to note that prices are subject to fluctuations in the steel market, which can be influenced by global economic conditions, trade policies, and supply-demand dynamics. Therefore, it is advisable to consult with steel suppliers or monitor market trends to get the most accurate and up-to-date pricing information.

- Q: Can steel coils be coated with zinc?

- Yes, steel coils can be coated with zinc through a process known as galvanization.

- Q: Are steel coils used in furniture manufacturing?

- Yes, steel coils are commonly used in furniture manufacturing for various purposes such as providing support and stability to seating structures, enhancing durability, and ensuring proper weight distribution.

- Q: I have a necklace that has a pendent made out of stainless steel. The pendent is connected by a cord, not chain, that I can take on and off; so, I leave it on all the time. It has gotten pretty tarnished because of that.

- steel jewelry Daily care? Just need a soft cloth just fine. Or you can use toothpaste to clean the stailess steel jewelry.

- Q: What are the different steel coil specifications?

- There are various steel coil specifications available, including dimensions (thickness, width, and length), chemical composition, mechanical properties (such as tensile strength and yield strength), surface finish, and coating options. These specifications vary depending on the specific application and industry requirements.

- Q: What are the different coating options for steel coils?

- There are several coating options available for steel coils, each serving different purposes and providing unique benefits. Some of the commonly used coating options for steel coils include: 1. Galvanized Coating: This coating involves immersing the steel coils in a bath of molten zinc, creating a layer of zinc on the surface. Galvanized coating provides excellent corrosion resistance and protects the steel from rusting. It is commonly used in applications where the steel coils are exposed to harsh environments or moisture. 2. Galvannealed Coating: This coating is a combination of galvanizing and annealing processes. The steel coils are first galvanized and then annealed to create a layer of zinc-iron alloy on the surface. Galvannealed coating offers enhanced paintability and weldability while providing good corrosion resistance. 3. Aluminum-Zinc Alloy Coating: Also known as Galvalume, this coating consists of an aluminum-zinc alloy applied to the steel coils. It provides excellent corrosion resistance and heat reflectivity, making it suitable for various applications, including roofing, siding, and automotive parts. 4. Organic Coatings: These coatings are typically applied as a top layer over a base coat of galvanized or galvannealed coating. Organic coatings can be in the form of paints, lacquers, or powder coatings. They provide additional protection against corrosion, UV rays, and abrasion, while also enhancing the aesthetics of the steel coils. 5. Chromate Conversion Coating: This coating is primarily used as a pre-treatment before applying organic coatings. It helps improve adhesion between the steel surface and the organic coating, ensuring better corrosion resistance. The choice of coating depends on various factors such as the intended application, environmental conditions, desired appearance, and budget. Manufacturers and end-users should carefully consider these factors to select the most suitable coating option for their specific requirements.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: My mother is in a weilding class, and today she accidentally welded Galvanized Steel. She doesn't feel good and she wants to know what the symptoms are for Galvanized Poisoning from breathing in the Fumes. Please help, I am worried for her.

- Galvanized Poisoning

Send your message to us

Hot sale Prepainted steel coil PPGI GI of CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords