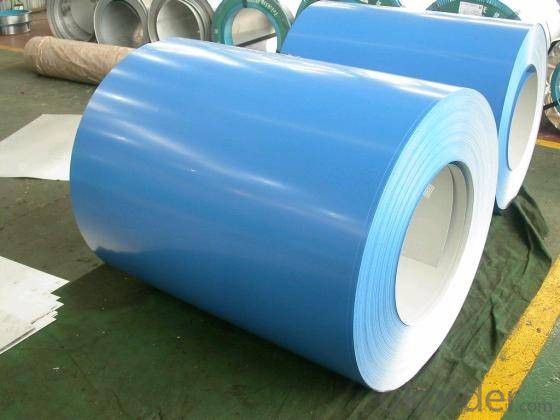

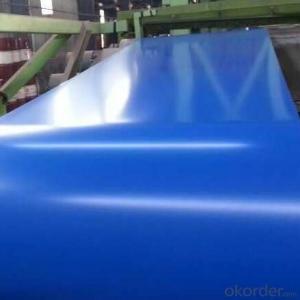

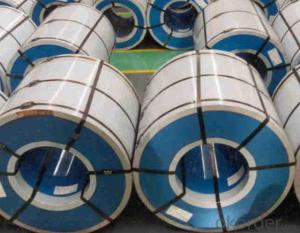

Prepainted Rolled Steel Coil for Construction Roofing Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the common applications of steel coils in construction?

- Steel coils are commonly used in construction for various applications such as roofing, siding, structural framework, and reinforcement in concrete structures.

- Q: How do steel coils contribute to the transportation industry?

- Steel coils contribute to the transportation industry by being used to manufacture various components and structures for vehicles, such as the body frames, chassis, and suspension systems. These coils are also used in the production of shipping containers, railcars, and cargo ships, ensuring the safe and efficient transportation of goods across different modes of transport.

- Q: so i just bought a stainless steel bracelet.......and recently found out that stainless steel isnt actually stainless..........will turpentine ruin it

- real s/steel is nickel and chrome, however manufacturers of kitchenware, e.g s/teel cutlery use the cheaper version of nickel chrome and iron, that is why some s/steel products rust, so if you want to test any products carry asmall magnet and test the article

- Q: How are steel coils handled during transportation to prevent damage?

- Steel coils are typically handled with extreme care during transportation to prevent damage. They are secured tightly using steel strapping or bands to prevent any movement or shifting during transit. Additionally, protective packaging materials, such as wooden or steel crates, are often used to provide extra cushioning and stability. Specialized equipment, such as forklifts or cranes, are used to lift and load the coils onto trucks or containers, ensuring safe and secure transportation.

- Q: I have a need to connect various stainless steel tubes and fitting together and was wondering how to do it. I know a TIG welder is an option but have heard rumors that there is a way to solder it in much the same way you affix copper pipe. Perhaps with higher heat and different flux. I need step by step and maybe suppliers of the materials. Thanks in advance and please I do not need the call a plumber answers as I've gotten in the past

- Soft Soldering All grades of stainless steel can be soldered with lead-tin soft solder. Leaded solders should not be used when the product being soldered is used for food processing, serving or transport. Soldered joints are relatively weak compared to the strength of the steel, so this method should not be used where the mechanical strength is dependent upon the soldered joint. Strength can be added if the edges are first lock-seamed, spot welded or riveted. In general, welding is always preferable to soldering. Recommended procedure for soldering: · 1. The steel surfaces must be clean and free of oxidation. · 2. A rough surface improves adherence of the solder, so roughening with grinding wheel, file or coarse abrasive paper is recommended. · 3. Use a phosphoric acid based flux. Hydrochloric acid based fluxes require neutralising after soldering as any remnant traces will be highly corrosive to the steel. Hydrochloric acid based fluxes are not recommended for soldering of stainless steels. · 4. Flux should be applied with a brush, to only the area being soldered. · 5. A large, hot iron is recommended. Use the same temperature as for carbon steel, but a longer time will be required because of stainless steel's low thermal conductivity. · 6. Any type of solder can be used, but at least 50% tin is recommended. Solder with 60-70% tin and 30-40% lead has a better colour match and greater strength.

- Q: Went to top gun range in Houston, Tx. Guy there said no steel bullets..Anyone know why? Think i can shoot them anywhere else? Perhaps an outdoor gun range? The are monarch FMJ 9mm steel rounds..Thanks!

- However, I cannot under any circumstance travel with loaded rifle magazines in my car. Those I have to load at the range because it would be illegal for me to travel to the range with loaded magazines. Even if I don't have a rifle in the car, I cannot possess loaded rifle magazines while traveling. All long guns (shotguns included) must be unloaded and secured in the vehicle, including magazines or tubes. There are several states with restrictions against traveling with loaded rifle magazines, so I'd suggest you check your state laws first, and if it is permissible in your state, then find out if the range will allow it too.

- Q: Project for school, we're learning about periodic elements and we have to choose an item from our hobbies to research what its made of. Any ideas on steel guitar strings??

- Steel is usually mainly made up of Iron (Fe) element, but it can also include Carbon (C) for a stronger steel or Nickel (Ni) for stainless steel.

- Q: What are the advantages of using pre-painted steel coils?

- There are several advantages to using pre-painted steel coils. Firstly, pre-painted steel coils have a protective coating applied during the manufacturing process, which makes them resistant to corrosion and increases their lifespan. Additionally, the pre-painted coating provides a smooth and aesthetically appealing finish, eliminating the need for further painting or finishing. This saves time and money on additional coatings or treatments. Moreover, pre-painted steel coils are available in a wide range of colors and finishes, allowing for greater design flexibility and customization. Lastly, pre-painted steel coils are easy to install, lightweight, and have excellent durability, making them an ideal choice for various applications in construction, automotive, and other industries.

- Q: hi i was doing a little history project on guns. i was just wondering if anyone could help me find out what material was used before steel and why this material wasnt as good as steel ( its faults)thanks for your help

- The most common was bronze, which was the strongest material that could be cast, at least until the industrial revolution. Until that time, furnaces which could reach temperatures hot enough to melt steel did not exist. The only way to work with steel would have been forging, which means hammering it into shape while red-rot. Obviously, this is not a very practical method for making large thick-walled cannons (though it was done on occasion. Small arms such as pistols and muskets could be easily made of steel by hand forging.) The most practical way to make cannons was pouring molten bronze which melts at significantly lower temperature than steel. Cast iron was also used. Note that Cast Iron contains 3%-7% carbon, compared to steel which only contains between 2% to 0.2% carbon. Due to the excessive carbon content of cast iron, it's melting point is about 500 degrees lower than steel enabling it to be melted with pre-industrial furnaces. Unfortunately, cast iron is also brittle, unlike steel or bronze. This means that a defective or cracked casting could easily explode, sending iron shrapnel everywhere. (Also, maiming and killing the gun crew, an experienced gun crew was as valuable as the cannon itself!) For this reason. Cast iron cannon were usually considered a cheap, risky alternative to expensive but durable bronze.

- Q: What are the typical lead times for steel coil orders?

- The typical lead times for steel coil orders vary depending on factors such as the supplier, quantity, and specifications required. However, lead times can range from a few weeks to several months, with an average of 6-8 weeks being common.

Send your message to us

Prepainted Rolled Steel Coil for Construction Roofing Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords