Prepainted Galvanized/Aluzing Steel coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Details

Basic Info.

Model NO.:G550, FULL HARD, SGHC

Type:Steel Coil

Standard:ASTM, GB, JIS

Certification:ISO, SGS, BV

Surface Treatment:Coated

Technique:Hot Rolled

Special Use:High-strength Steel Plate

Base Metal:Galvanized or Galvalume Steel

Width:914/1000/1200/1219/1220/1250mm

Thickness:0.16-1.2mm

Zinc-Coating:Z50-150G/M2 or Az40-100G/M2

Top Side Painting:15-25 Micron

Back Side Painting:5-8 Micron

Colour:Ral Standard or According to Customers′ Requirment

Coil Weight:3-6 Mt

Coil ID:508/610 Mm

Export Markets:North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Packing:Seaworthy Packing

Standard:0.135-1.2MM

Origin:China, Shandong

HS Code:72107000

Production Capacity:180000mt

Product Description:

1. Standard: AISI, ASTM, BS, DIN, GB, JIS, ASTM, JIS, GB

2. Steel Grade: DX51D, SGCC, SGCH, SPCC, SPCD, DC01, ST12, ST13, Q195, 08AL

3. Thickness: 0.13-0.5mm

4. Width: 600-1250mm

5. Length: Up to The Thickness or as require

6. Spangle: Zero, Mini, Regular, Big, Skin Pass

7. Audited Certificates: BV, SGS, ISO, CIQ

8. Zinc Coating: 40g-200g

9. Surface: Chromated, dry/oiled, Cr3 treated anti-finger

10. Package: Standard exporting package (or as required)

11. ID: 508/610mm

Specification:

| commodity | Color Coated Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Base metal | galvanized, galvalume, cold rolled steel |

| Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness) |

| Width | 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-7 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

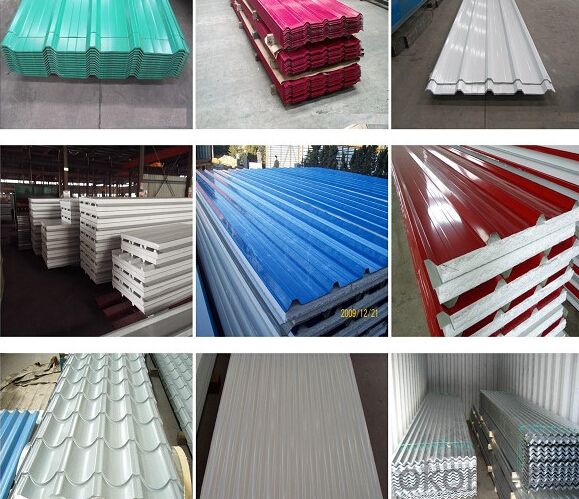

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

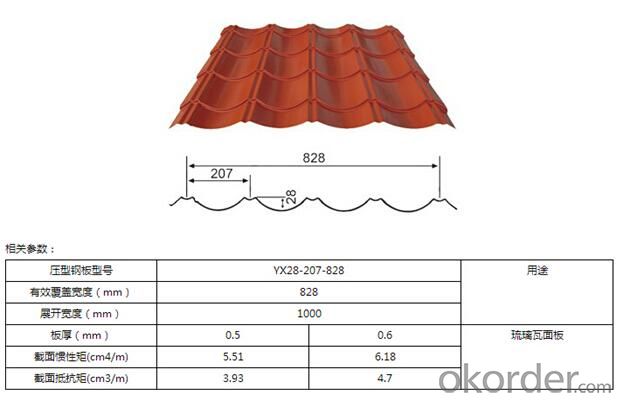

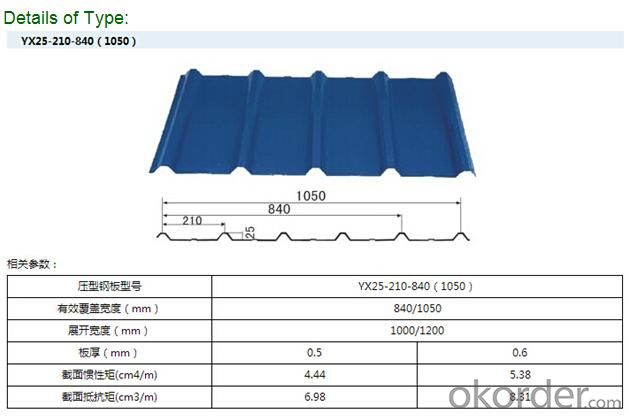

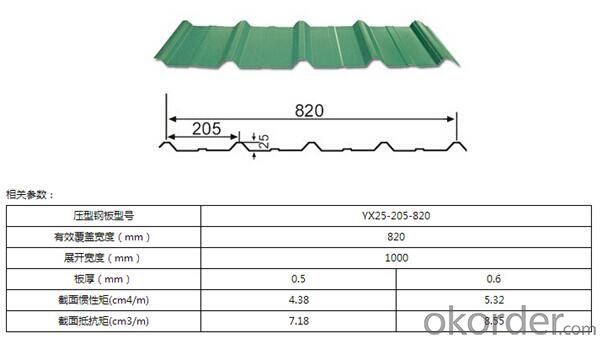

Details of Type:

FAQ:

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: How are steel coils used in the production of shipping pallets?

- Steel coils are used in the production of shipping pallets to reinforce and strengthen the structure. The coils are typically placed within the base of the pallet to provide additional support and stability, allowing the pallet to bear heavier loads and resist bending or warping during transportation.

- Q: I have been searching on pots and pans, how can I find out if it's really stainless steel, someone told me if a magnet sticks to it it's real stainless steel is this true?

- Magnets stick to some stainless but not all of it, so a magnet is not a reliable indicator.

- Q: What is the role of steel coils in the manufacturing of appliances?

- Steel coils play a crucial role in the manufacturing of appliances as they serve as the primary material for constructing the appliance's body and various components. The coils are processed, shaped, and transformed into different parts, such as the outer casing, inner structures, and internal components, providing strength, durability, and stability to the appliances. Additionally, the steel coils can be easily customized to meet specific design requirements, ensuring the appliances are efficient, reliable, and capable of withstanding the demands of daily use.

- Q: I want to purchase steel for construction purpose, What aspects should I keep in mind while deciding that which company should I contact for this?

- I okorder /

- Q: Can steel coils be coated with vibration-damping materials?

- Yes, steel coils can be coated with vibration-damping materials. These materials, such as rubber-based compounds or specialty coatings, can help reduce vibrations and dampen the noise generated by the steel coils during operation.

- Q: How are steel coils used in the manufacturing of pipes and tubes?

- Steel coils are used in the manufacturing of pipes and tubes by being unwound and fed into a pipe or tube mill. The steel coils are then shaped and welded together to form a continuous pipe or tube, which is further processed and finished according to specific requirements.

- Q: I'v had 5 people at school say steel is stonger than Titanium and some(5) kids at school say titanium stronger then steel but i looked it up on the internet and i got soem web sites that say steel is stronger then titanium and some sites that say titanium is stonger then steel sooooo???? witch one is strongerPS i no tungsten is stronger then steel.... and titanium.................

- TITANIUM is stronger than STEEL. For steel:(I am taking high tensile steel)- Material Yield strength(MPa) -1650 Ultimate strength-(MPa) -1860 density(g/cm3)- 7.8 For Titanium:(Titanium is as strong as steel, but 45% lighter) Tensile Strength : 460-615 N/mm2 So, stregth to weight ratio is higher for titaneum. Titanium is as strong as steel but much less dense. It is therefore important as an alloying agent with many metals including aluminium, molybdenum and iron. These alloys are principally used in aircraft and missiles as they are materials which have low density yet can withstand extremes of temperature. Titanium also has potential use in desalination plants which convert sea water to fresh water. The metal has excellent resistance to sea water, and so is used to protect the hulls of ships, and other structures exposed to sea water. However, the largest use of titanium is in the form of titanium(IV) oxide, which is extensively used in both house paint and artists’ paint. This paint is also a good reflector of infrared radiation and so is used in solar observatories where heat causes poor visibility. please read below:;;; The tensile strength of a material is the maximum amount of tensile stress that it can be subjected to before failure. The definition of failure can vary according to material type and design methodology. This is an important concept in engineering, especially in the fields of material science, mechanical engineering and structural engineering. There are three typical definitions of tensile strength: Yield strength - The stress a material can withstand without permanent deformation. This is not a sharply defined point. Yield strength is the stress which will cause a permanent deformation of 0.2% of the original dimension. Ultimate strength - The maximum stress a material can withstand. Breaking strength - The stress coordinate on the stress-strain curve at the point of rupture.

- Q: How are steel coils used in the manufacturing of power transmission towers?

- Steel coils are used in the manufacturing of power transmission towers by being cut, shaped, and welded together to form the structural components of the towers. The coils provide a strong and durable material that can withstand the weight and stress of the tower, ensuring its stability and longevity.

- Q: What are the factors affecting the formability of steel coils?

- There are several factors that can affect the formability of steel coils, including the composition and microstructure of the steel, the thickness and width of the coils, the temperature at which the forming process takes place, the lubrication used during forming, and the equipment and techniques employed.

- Q: i want to buy an exhaust but whats the difference between satinless steel and titanium exhaust?

- titanium is a light-weight silvery metallic element that is corrosion-resistant while a stainless steel is a steel containing atleast 12 % chromium and is also corrosion-resistant. both are good choices for a new exhaust.

Send your message to us

Prepainted Galvanized/Aluzing Steel coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords