Prepainted Rolled steel Coil for Construction Roofing use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

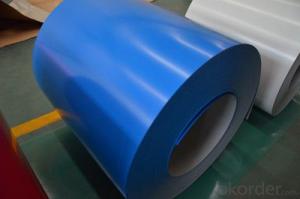

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the typical size and weight of a steel coil?

- The typical size and weight of a steel coil can vary depending on its intended use and industry standards. However, a common size for a steel coil is around 36 inches in width and weighs approximately 5 to 10 tons.

- Q: What is the process of pickling and oiling steel coils?

- The process of pickling and oiling steel coils involves several steps to ensure the quality and protection of the steel. Firstly, pickling is the process of removing impurities and scale from the surface of the steel coil. This is typically done by immersing the coil in an acid bath, such as hydrochloric acid or sulfuric acid, which helps to dissolve any oxides, rust, or other contaminants present on the surface. This step is crucial as it prepares the steel for further processing and prevents any potential defects or corrosion. After pickling, the steel coils are rinsed with water to remove any residual acid and then dried. Once the coils are clean and dry, they are then coated with a layer of oil to provide temporary corrosion protection and lubrication during subsequent handling and transport. The oil coating helps to prevent the steel from rusting or oxidizing before it is further processed or used in various applications. The oiling process can be done in several ways. One common method is by applying the oil using a roller or brush, ensuring that the entire surface of the coil is evenly coated. Alternatively, the coils can be passed through a bath or spray chamber where the oil is applied. The type of oil used can vary depending on the specific requirements of the steel and its intended use. Some common oils include mineral oil, synthetic oils, or specialized rust-preventive coatings. Once the oiling process is complete, the steel coils are typically stacked, wrapped, or packaged for storage or transportation. It is important to handle the coils carefully to avoid damaging the oil coating and compromising the corrosion protection. Overall, pickling and oiling steel coils are essential steps in the steel manufacturing process to ensure the quality, cleanliness, and protection of the steel, ultimately extending its lifespan and enhancing its performance in various applications.

- Q: How are steel coils used in the production of steel handles?

- Steel coils are used in the production of steel handles by being processed and shaped into the desired handle form. The coils are uncoiled and cut into appropriate lengths, which are then shaped and bent using various machinery and techniques. The resulting steel handles are sturdy, durable, and able to withstand the demands of everyday use.

- Q: What are the common coil transportation options?

- The common coil transportation options include trucking, rail transport, and sea freight.

- Q: What are the different types of steel coil slitting blades?

- There are several different types of steel coil slitting blades, including circular slitting blades, crush cut slitting blades, and razor slitting blades. Each type has its own unique design and is used for specific applications in the steel coil slitting process. Circular slitting blades are commonly used for high-speed slitting and provide precise and smooth cuts. Crush cut slitting blades are designed to crush and shear the material, making them suitable for cutting delicate or fragile materials. Razor slitting blades have a sharp edge that slices through the material, making them ideal for thicker or tougher materials. Overall, the choice of blade type depends on the specific requirements of the slitting process and the type of material being cut.

- Q: How are steel coils transported?

- Steel coils are typically transported using specialized flatbed trucks or railcars. The coils are carefully loaded onto these vehicles and secured using straps or chains to prevent any movement during transit. In some cases, shipping containers are also used to transport steel coils via cargo ships.

- Q: How are steel coils used in the production of metal cabinets?

- Steel coils are a vital element when producing metal cabinets, as they consist of thin steel sheets tightly wound into coils. To begin using steel coils for metal cabinet production, the first step is to uncoil them. This involves unwinding the coil and feeding the steel sheet into a machine that cuts it to the desired length, depending on the size and dimensions of the metal cabinet being manufactured. Once the steel sheet has been cut, it undergoes a process known as blanking. This entails cutting out the necessary panels and parts for the metal cabinet, including the sides, top, bottom, and doors. The blanking process is typically carried out using a stamping press or laser cutting machine to ensure precise shaping of the steel sheet. Following the blanking process, the individual panels are then formed and shaped using a series of bending and forming machines. These machines apply pressure and force to the steel panels, bending them into the desired shape and creating the necessary angles and curves required for the metal cabinet design. After the panels have been formed, they are typically joined together using welding or fastening techniques. Welding involves using heat to fuse the edges of the steel panels together, while fastening techniques may involve the use of screws, bolts, or rivets to securely hold the panels in place. In summary, steel coils are essential in the production of metal cabinets as they provide the raw material for creating the individual panels. The use of steel coils allows for greater flexibility and efficiency in manufacturing metal cabinets, enabling mass production and customization of cabinet designs.

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- 154cm is a very good knife steel, the problem is in the heat treating. Stainless should be cryo treated to get all it can offer. That being said, if you really want to drop some coin, look at getting one made from CPM 440V. Stainless isn't as strong as carbon but on a smaller knife works well. You might also look for D-2 Tool steel. There are factory knives that are made of that.

- Q: What does INOX Steel means?I have been looking up the meaning but cannot find it... please help...

- Inox Steel

- Q: How do steel coils affect the quality of finished products?

- Steel coils can greatly impact the quality of finished products in various industries. One of the key ways steel coils affect product quality is through their dimensional accuracy and consistency. When the steel coils are not properly manufactured or have irregular dimensions, it can lead to issues in the production process and result in finished products that do not meet the desired specifications. Furthermore, the surface quality of steel coils is critical in determining the final appearance and performance of the finished products. Coils with surface defects, such as scratches, rust, or unevenness, can negatively impact the aesthetic appeal of the products, making them less desirable to customers. Moreover, these defects can also affect the functionality and durability of the finished products, leading to potential failures or reduced lifespan. The mechanical properties of steel coils also play a vital role in determining the quality of finished products. Coils with inconsistent or inadequate mechanical properties can compromise the strength, toughness, and overall performance of the end products. For example, in industries such as automotive or construction, where strength and reliability are crucial, the use of steel coils with the wrong mechanical properties can lead to safety hazards or structural failures. Additionally, the chemical composition of steel coils can significantly influence the quality of finished products. The presence of impurities or variations in the alloying elements can affect the material's corrosion resistance, weldability, and other essential properties. This, in turn, can impact the longevity and functionality of the final products. In summary, steel coils have a substantial impact on the quality of finished products. Their dimensional accuracy, surface quality, mechanical properties, and chemical composition all contribute to the overall performance, appearance, and durability of the end products. Therefore, it is crucial to ensure that steel coils used in manufacturing processes meet the desired standards to achieve high-quality finished products.

Send your message to us

Prepainted Rolled steel Coil for Construction Roofing use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords