BMP Prepainted rolled Steel Coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

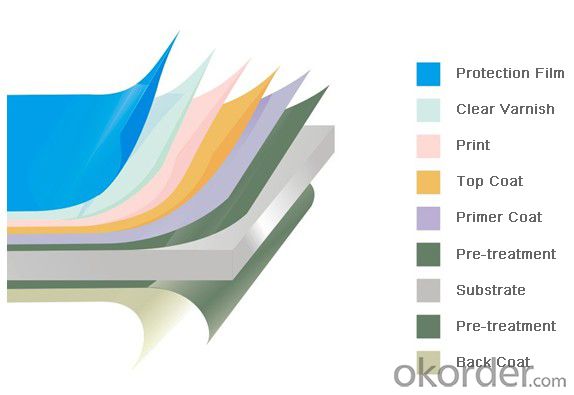

Structure of BMP Prepainted rolled Steel Coil for Construction Roofing constrution

Description of BMP Prepainted rolled Steel Coil for Construction Roofing constrution

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling.

Main Feature of BMP Prepainted rolled Steel Coil for Construction Roofing constrution

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of BMP PPGI Prepainted rolled Steel Coil for Construction Roofing constrution

Refrigerators, frozen food display cabinets, washing machines, electric ovens, vending machines, air conditioners, copiers, switchgear, instrument cabinets, electric fans, vacuum cleaners and so on.

Transport: Car ceiling, backplane, hoardings, interior trim panels, car shell, trunk panels, car dashboard, console shell, tram, train ceiling, partitions, wall, door, ships separated Swatchesdoors, furniture board, flooring, container, etc.

Sheet metal processing and furniture applications: Ventilation and heating stoves, water heaters, shell, counters, shelves, signs, wardrobe, desk, bedside cabinets, chairs, lockers, file cabinets, bookshelves.

Exact Rate As Per Your Request.

Specifications of BMP Prepainted rolled Steel Coil for Construction Roofing constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances, |

FAQ of BMP Prepainted rolled Steel Coil for Construction Roofing constrution

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc .

- Q: I am thinking about getting a cold steel tilite or a kershaw leek or possibly a buck sirus. If you have had any experience with these knives please give it to me. thanks

- Cold Steel uses an incredible quality of metal. If you want very durable go with that. The benefit to Kershaw is they make better folders. Fixed blade--go with Cold Steel. Folder, go with Kershaw. I get all my knives from the guys below, they have free shipping and really good prices.

- Q: does anyone out there know where to get a good deal on a pedal steel guitar? i am from northern indiana and i'm willing to travel some if i have to.i am just getting into pedal steel guitar and i really don't have any idea what i need. i don't know how to play a guitar (i do know how to play the piano and the drums) at all but i want to learn to play the pedal stell guitar and i can't do that without getting one first so, if anyone can help me out i would greatly appreciate it! :o)

- I agree with everything that Lester said. Another thought is to consider starting on a lap steel guitar rather than a pedal steel - its related, a little easier to learn on, and less expensive. Once you get proficient on the lap steel, you can move up to the pedal steel. Good luck!

- Q: I am currently writing a manuscript, and would like to know whether guns made out of steel, burn or melt when exposed to flames. Thanks.

- Steel melts around 2500°F (1370°C). That's hotter than most normal fires (obviously, your steel pots don't melt on the stove, do they?) but a blowtorch or something like that could do it.

- Q: How are steel coils used in the manufacturing of steel drums?

- Steel coils are used in the manufacturing of steel drums by being shaped and welded into the cylindrical body of the drum. The coils are unrolled and cut to the desired length, then formed into a circular shape and welded together to create a seamless drum.

- Q: How are steel coils used in the production of construction components?

- Steel coils are used in the production of construction components by being processed into various shapes and sizes, such as beams, columns, and plates. The coils are unwound and then cut, bent, or shaped to meet the specific requirements of the construction project. Additionally, the high strength and durability of steel make it a preferred material for construction, ensuring the components can withstand heavy loads and harsh environmental conditions.

- Q: will peircers use surgical steel? how do you know for sure what they are using?

- When you go to get your tongue pierced they will tell you exactly what their doing and what their using. And I had my belly button pierced, and my boyfriend has his tongue and eye brow pierced and it's all done with surgical steel. Piercers wont use anything but that.

- Q: Having a new kitchen and would like to know the pros and cons of stainless steel as opposed to white appliances. I can only think of finger marks on the SS, which I believe are difficult to remove. Anyone had both that they could advise please?

- I have Stainless Steel and YES it shows finger prints etc, Since there are no children around it's easier to keep clean, but one word of caution when using commercial SS cleaners, if the spray gets onto the floor it's almost impossible to get off and makes it slippery as ice. I'd use newspaper before using a SS cleaner,, I've had both and would opt for WHITE in any case. So easy to maintain, Now, they do make a Faux SS, which is very nice., and don't show any markings at all, our Son has one and with 3 kids in the house constantly using the Fridge it's been great, you might want to look into that..

- Q: How are steel coils used in the production of HVAC equipment?

- Steel coils are used in the production of HVAC equipment as they serve as the primary components for heat transfer. These coils are responsible for facilitating the transfer of heat between the air and refrigerant, ensuring efficient cooling or heating of the air circulating within the HVAC system.

- Q: How do steel coils contribute to sustainability in manufacturing?

- Steel coils contribute to sustainability in manufacturing in several ways: 1. Recyclability: Steel is one of the most recycled materials in the world, with a recycling rate of over 90%. Steel coils are made from recycled steel and can be recycled again at the end of their life cycle. This reduces the need for extracting raw materials, conserves natural resources, and reduces energy consumption and greenhouse gas emissions associated with steel production. 2. Durability: Steel is known for its strength and durability. Steel coils are designed to withstand heavy loads, extreme temperatures, and harsh environmental conditions. This means that products made from steel coils, such as automotive parts, construction materials, and appliances, have a longer lifespan, reducing the need for frequent replacements and minimizing waste. 3. Energy efficiency: Steel coils are used in various manufacturing processes, such as stamping, forming, and welding. These processes require less energy when working with steel coils compared to other materials. Steel's high strength-to-weight ratio allows for the production of lightweight yet strong components, reducing energy consumption during transportation and improving fuel efficiency in vehicles. 4. Reduced emissions: Steel coils contribute to sustainability by helping manufacturers reduce their emissions. Steel is a low-carbon material, and its production emits fewer greenhouse gases compared to other materials like aluminum or plastics. By using steel coils, manufacturers can reduce their carbon footprint and contribute to climate change mitigation efforts. 5. Circular economy: Steel coils are a key component in the circular economy, which aims to minimize waste and maximize resource efficiency. Steel coils can be easily recycled and reused, ensuring that they remain in the production cycle for a longer time. This reduces the need for virgin materials and promotes a more sustainable and circular approach to manufacturing. In conclusion, steel coils contribute to sustainability in manufacturing by being recyclable, durable, energy-efficient, emission-reducing, and promoting a circular economy. By choosing steel as a material and utilizing steel coils, manufacturers can make significant strides towards reducing their environmental impact and fostering a more sustainable manufacturing industry.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications. They are utilized in the manufacturing of pipelines, storage tanks, and other equipment due to their strength, durability, and resistance to corrosion. Steel coils are also employed in the construction of offshore platforms and drilling rigs, where they provide structural support and ensure the safety and reliability of the infrastructure.

Send your message to us

BMP Prepainted rolled Steel Coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords