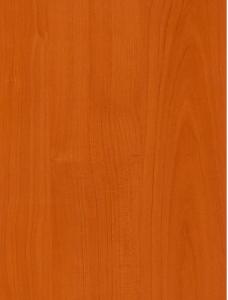

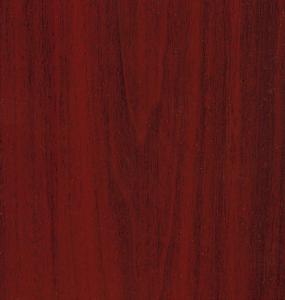

Pre-painted Galvanized Steel Coil-EN10169-WOODEN9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: Can steel coils be coated with silicon?

- Yes, steel coils can be coated with silicon through a process known as siliconizing or silicon coating. This enhances the steel's resistance to corrosion, improves its electrical conductivity, and provides other beneficial properties.

- Q: How are steel coils welded together?

- Steel coils are typically welded together using one of two methods: either by resistance welding or by arc welding. In resistance welding, the coils are pressed together and an electric current is passed through them, generating heat and causing the coils to fuse together. Arc welding, on the other hand, involves the use of an electric arc that melts the edges of the coils, creating a molten pool. As the pool solidifies, the coils bond together, forming a strong weld. Both methods ensure a secure and durable connection between the steel coils.

- Q: How are steel coils used in the production of storage racks?

- Steel coils are used in the production of storage racks by being uncoiled, cut, and shaped into the required dimensions and components of the racks. These steel coils provide the necessary strength and durability to support heavy loads and ensure the stability and longevity of the storage racks.

- Q: How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q: Why is the selection of steel building erector of extreme importance while starting a new steel building project?

- Because if the beaming is screwed up, everything in the building is at risk. Also, if the erector runs late, everything else is delayed. An incompetent erector can actually cause damage to the beams [especially if inadequate bracing leads to collapse] and getting new ones can severely delay the project.

- Q: How do steel coils affect the quality of finished products?

- Steel coils can have a significant impact on the quality of finished products. Their quality, including dimensions, surface condition, and mechanical properties, directly affects the final product's strength, durability, and appearance. Coils with inconsistent dimensions or surface defects can lead to uneven or weak finished products. Similarly, if the mechanical properties of the coils do not meet the required specifications, it can compromise the performance and functionality of the end product. Therefore, ensuring the high quality of steel coils is crucial for achieving superior finished product quality.

- Q: If i get a samurai sword made of carbon steel, what is the hardest thing i can hit before it breaks? Or will it not break?

- If you can get it, and it is not in a museum or owned by a wealthy collector it is probably junk. a realsamuari ( warrior) sword probably took a year or more to make, 6 months or so to sharpen and was tempered by dipping in the blood of a peasant. It might have been marked by the number of human bodies it could cut through in one stroke ,1 was a minimum by all accounts they were the finest steel weapons ever made the curved thing in a knife shop is a cheap knock off

- Q: Why is the steel tape tape head not fixed?

- It makes sense to be irregular;You can see the standard ruler of steel roll head is a gap, when you take the time to object quantity, the head will indent the gap, so you measure is the size of the head from the head of steel;When you hook the object, the head will pull apart and you'll take the dimension from the end of the steel head.

- Q: aLSO, DOES STEEL C45 REFER TO THE CARBON IN IT?ALSO, WHAT IS AIRCRAFT GRADE PLYWOOD AND WHERE DOES ONE GET IT

- chromium nickle steel aka stainless steel exact amount of chrome and nickle will determine type/grade numbers Check the google for steel type/grade Never head of aircraft grade, however,, there is marine grade - normally baltic birch with waterproof glue and no defects i.e. knots, etc. Very strong (also quite expensive) but worth it for the correct applications

- Q: Okay basically bought my girlfriend Tiffany sterling silver necklace for her birthday and now christmas is coming up i want to buy her this DG Necklace. BUT i have discovered its steel. And its ?110. I am not a rich man i am infact quite young and we have been together for an incredibly long time! I wanted to know is Steel seen as a cheap necklace, whats your say? Don't give me all this bull about her being grateful as she does not expect this. BUT I WANT IT TO BE NICE. Whats your say? Is Steel good? Does it get dirty? Does it shine? Is it worth it? Thanks x

- Things about steel~ Basically indestructable Should be non magnetic It shines Why not get it

Send your message to us

Pre-painted Galvanized Steel Coil-EN10169-WOODEN9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords