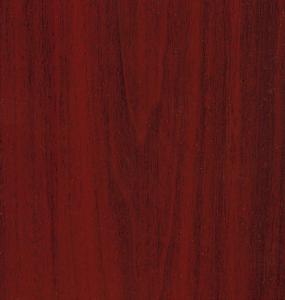

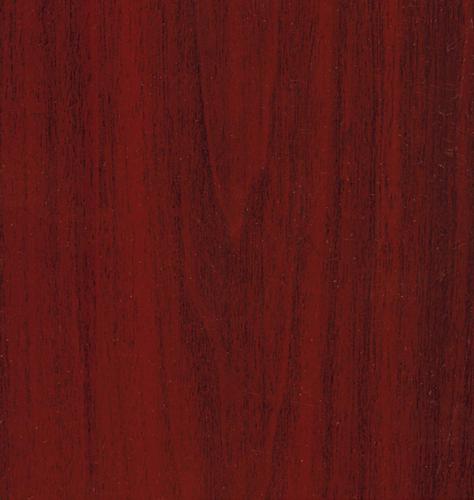

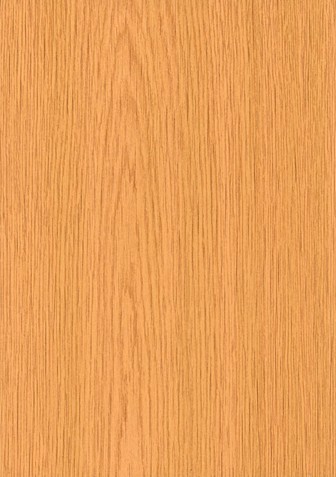

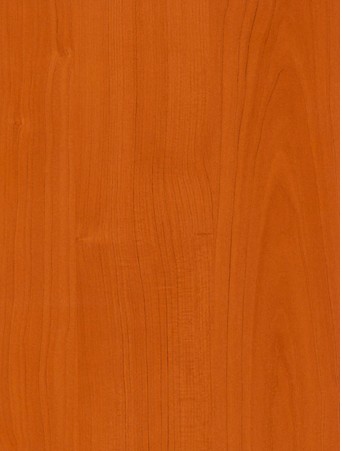

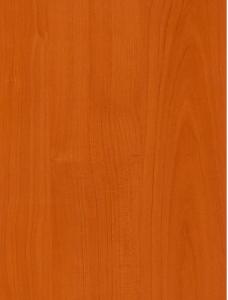

Pre-painted Galvanized Steel Coil-EN10169-WOODEN4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: a concrete or steel building?also, what is the density of concrete and steel? is concrete heavier in steel for the same volume?

- Steel is heavier than concrete for the same volume, however steel buildings are generally lighter. This is because steel buildings utilize high strength of steel, so volume of steel in steel buildings is much smaller than volume of concrete in concrete buildings. In another words in steel buildings much less volume of material is needed for the same strength compared to concrete buildings.

- Q: How do steel coils contribute to the marine vessel construction industry?

- Steel coils are essential components in the marine vessel construction industry as they play a crucial role in the fabrication of various structural elements of ships and boats. These coils are typically made of high-quality steel and are used in a variety of ways to contribute to the construction and performance of marine vessels. Firstly, steel coils are utilized in the construction of the hull, which is the main body of the ship. The hull requires strong and durable materials to withstand the harsh conditions of the sea, including waves, corrosion, and impacts. Steel coils provide the necessary strength and integrity to the hull, ensuring the vessel's structural integrity and safety. Moreover, steel coils are also employed in the fabrication of decks, bulkheads, and other internal structures of marine vessels. These components are crucial for dividing the ship into compartments, providing stability, and supporting various equipment and machinery. Steel coils are known for their excellent tensile strength, which allows them to bear heavy loads and resist deformation, making them ideal for constructing these vital components. Additionally, steel coils are used in the construction of propulsion systems and other mechanical parts of marine vessels. These coils are often shaped and formed into specific components, such as shafts, gears, and propellers, which are critical for the vessel's propulsion and maneuverability. The high strength and durability of steel coils ensure the reliability and efficiency of these mechanical systems, enabling smooth navigation and operation of the vessel. Furthermore, steel coils contribute to the marine vessel construction industry by enhancing the overall safety and longevity of ships and boats. Steel is known for its resistance to corrosion, which is a significant concern in marine environments due to the presence of saltwater. By utilizing steel coils, marine vessels can withstand the corrosive effects of seawater, reducing the need for frequent maintenance and repair. This, in turn, improves the lifespan of the vessel and reduces the risk of accidents or failures at sea. In conclusion, steel coils are indispensable in the marine vessel construction industry. These coils provide the necessary strength, durability, and resistance to corrosion, ensuring the safety, performance, and longevity of ships and boats. From the construction of the hull to the fabrication of internal structures and mechanical components, steel coils play a vital role in every aspect of marine vessel construction.

- Q: Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- Elastic Limit Of Steel

- Q: Do any tour players use steel shafted woods? And are there any real advantages to having steel shafted woods? I have only played with one person to use steel shafted woods, he tells me thats because he cant hit it straight with graphite, however he is a very short hitter.

- I'd be very surprised if there are any tour players still using steel shafts on their woods (I did actually see Tiger with a steel shaft on a driver during a clinic in 2002). Top end graphite shafts have gotten so much better there's just no reason for pros not to use them anymore. That being said, I use a 45 True Temper stiff steel shaft in my driver (Cobra X-speed, 9.5*). Graphite is longer than steel, but the distance I've lost is minimal (maybe 10 yards and I still put it out there 250+ consistently). The extra weight has actually helped me stay in control which has improved my overall driving considerably, and the very low torque in a steel shaft has paid off huge in accuracy. You're paying minimum $60 (or more) for a graphite shaft with a similar torque rating to any steel shaft. I hit easily twice as many fairways since the switch. I've even switched out my other fairway woods too, the feel and control are so much nicer. I've considered going with a 46 on the driver to try to regain some of the distance, and at $7 per shaft I can actually just go do that whenever I want. Don't get me wrong, if I were playing for money or flirting with par I'd invest in good quality graphite stuff no question, but it doesn't make sense to me right now. I'd recommend to anyone looking for more consistency out of their woods to take $20 to your golf shop and try it out. It's a lot cheaper than the alternatives.

- Q: Which one has more electrical resistivity? Wood or steel? And why?I know that the resistivity depends on the material of the conductor, but i want a perfect explaination please.Thnx in advance :)

- Wood is made up of elements which are non-metals with a high electron affinity. Specifically, carbon, oxygen, hydrogen, and some nitrogen. Furthermore the covalent bond structure in wood means electrons are tightly bound and cannot move easily from atom to another. Not without adding a great deal of energy to the first. Steel is mostly iron, which is a metal. Metals have low electron affinity. The outer electrons in metals are bound very loosely, so that they can move from atom to atom using almost no energy. Metals tend to conduct electricity very easily.

- Q: I am looking at website on google based on the terms structural steel fabrication and simply steel fabricationI know that there must be a difference between the two terms, but it seems that many website authors use the two terms interchangeably.Do you know the key differences between the two terms?

- Structural steel is steel construction material, a profile, formed with a specific shape or cross section and certain standards of chemical composition and strength. Structural steel shape, size, composition, strength, storage, etc, is regulated in most industrialized countries. Fabrication, when used as an industrial term, applies to the building of machines, structures and other equipment, by cutting, shaping and assembling components made from raw materials. Small businesses that specialize in metal are called fab shops. Steel fabrication shops and machine shops have overlapping capabilities, but fabrication shops generally concentrate on the metal preparation, welding and assembly aspect while the machine shop is more concerned with the machining of parts.

- Q: How do steel coils affect the quality of finished products?

- The quality of finished products in various industries can be greatly influenced by steel coils. Dimensional accuracy and consistency are key factors that determine the impact of steel coils on product quality. When steel coils are not properly manufactured or have irregular dimensions, it can cause issues in the production process and result in finished products that do not meet the desired specifications. Moreover, the final appearance and performance of finished products are heavily dependent on the surface quality of steel coils. Defects such as scratches, rust, or unevenness in the coils can have a negative impact on the aesthetic appeal of the products, making them less desirable to customers. Additionally, these defects can compromise the functionality and durability of the finished products, potentially leading to failures or a reduced lifespan. The mechanical properties of steel coils also play a crucial role in determining the quality of finished products. Coils with inconsistent or inadequate mechanical properties can compromise the strength, toughness, and overall performance of the end products. This is especially important in industries like automotive or construction, where strength and reliability are of utmost importance. The use of steel coils with incorrect mechanical properties can lead to safety hazards or structural failures. Furthermore, the chemical composition of steel coils can have a significant impact on the quality of finished products. The presence of impurities or variations in the alloying elements can affect the material's corrosion resistance, weldability, and other important properties. This, in turn, can affect the longevity and functionality of the final products. In conclusion, steel coils have a significant influence on the quality of finished products. Their dimensional accuracy, surface quality, mechanical properties, and chemical composition all contribute to the overall performance, appearance, and durability of the end products. Therefore, it is essential to ensure that steel coils used in manufacturing processes meet the required standards to achieve high-quality finished products.

- Q: What are the different types of steel coil surface treatments for outdoor applications?

- For outdoor applications, there are several commonly used surface treatments for steel coils that enhance durability, corrosion resistance, and appearance. Examples of these treatments include: 1. Galvanized: This treatment involves applying a layer of zinc to the steel surface, providing excellent corrosion resistance. Galvanized steel coils have a shiny, silver appearance. 2. Galvalume: Galvalume is a combination of aluminum and zinc applied to the steel surface, offering superior corrosion resistance compared to galvanized steel. Galvalume steel coils have a duller, matte finish. 3. Painted: Steel coils can be painted with various coatings to enhance appearance and protect against corrosion. The paint can be applied in single or multiple layers, depending on the desired level of protection. Painted steel coils are available in a wide range of colors and finishes. 4. Powder Coated: This type of paint coating is applied as a powder and then cured under heat, resulting in a durable and long-lasting finish. Powder coated steel coils are resistant to chipping, scratching, and fading, making them suitable for outdoor applications. 5. Organic Coated: Organic coatings, such as PVC or PVDF, are applied to steel coils to provide additional protection against corrosion and weathering. These coatings are commonly used in architectural applications where aesthetics and durability are important. These various surface treatments for steel coils offer different levels of protection and aesthetic options for outdoor applications. The choice of treatment depends on factors such as the intended use, environmental conditions, and desired appearance.

- Q: I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the metal only makes it look nicer, but does nothing to improve the function of the blade.What do you think of this?

- This Site Might Help You. RE: Does folding modern steel do anything to enhance a sword? I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the...

- Q: is surgical steel or sterling silver belly button rings better for you? surgical is really cheap so its sketch and i justt dont want it to mess up

- Sterling Silver Belly Rings

Send your message to us

Pre-painted Galvanized Steel Coil-EN10169-WOODEN4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords