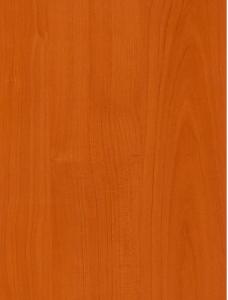

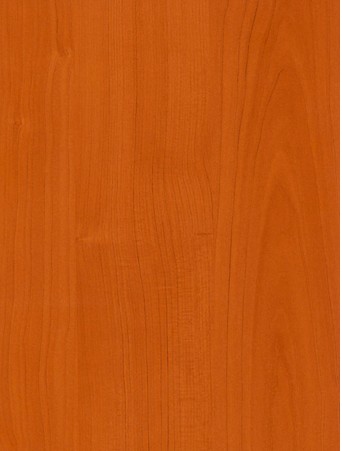

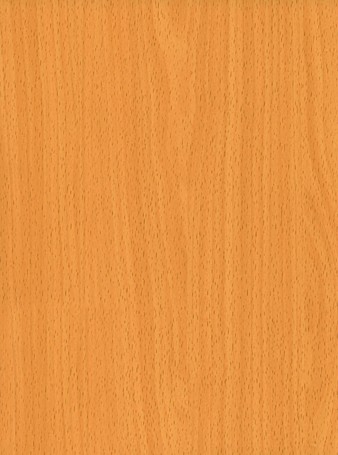

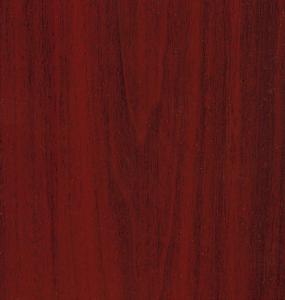

Pre-painted Galvanized Steel Coil-EN10169-WOODEN10

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: I thought it was STAINLESS STEEL! I have stainless steel can openers spatulas that are rusty. What's up with that? did you know that braces on people's teeth are made of stainless steel? That's why they call people metal-mouth. I used to have braces.

- steel is a iron alloy with composites like carbon and with a minimum chromium percentage of 10.5 ...and the strength and other properties are closely related to the percentage of carbon and chromium used in it..! its the chromium that creates a thin oxide layer maintaining the lustre by preventing the alloy from forming the iron oxide which is often reffered as rust..so if you got your stainless steel rusted you are betryed by the manufactures and may be they have failed to anticipate the sorrounding environment so that they selected a compostion that best suits..!! cheers..!

- Q: What are the different coil leveling line configurations used for steel coils?

- The steel industry utilizes various coil leveling line configurations to meet specific requirements and preferences. Some commonly employed configurations include: 1. Straightener: Employed to rectify coil shape defects or distortion. It consists of rollers that gradually straighten the coil. 2. Leveler: Ensures consistent thickness throughout the coil. Utilizes rollers to flatten the coil to the desired thickness. 3. Combination Straightener/Leveler: Integrates both straightening and leveling functions into a single machine. Combines rollers and straightening elements for shape correction and thickness leveling in one pass. 4. Looping Pit: Allows continuous processing of accumulated coils. Serves as a buffer between the entry and exit sections of the leveling line, accommodating variations in coil supply and demand. 5. Tension Leveler: Applies tension during leveling to remove shape defects and achieve a flat, uniform surface. 6. Rotary Shear: Incorporates a synchronized rotary shear to cut the leveled coil accurately and precisely. These examples showcase the diverse coil leveling line configurations used in the steel industry. The choice of configuration depends on factors such as desired product specifications, coil dimensions, processing speed requirements, and budget considerations.

- Q: I know this is an alloy, but can it be mixed to form a superior steel? Therefore less likely to stain?

- Unfortunately the stainless property does not make a 100% superior blade, unless you are not too concerned with how it performs. Generally speaking the mineral that allows steel not to stain is chromium so the higher content of chromium the more shiny and less likely to stain. The best performing blades however are the ones resistant to fatigue that usually contain high silica levels like japanese blades. Chromium on the other hand does make a less flexible and lower quality blade that also needs to be thicker, so it comes down to what will you be using it for.

- Q: What are the different types of steel coil surface treatments for indoor applications?

- There are several different types of steel coil surface treatments that are suitable for indoor applications. These treatments are designed to enhance the appearance, durability, and performance of the steel coil in various indoor environments. Some of the common surface treatments for indoor applications include: 1. Galvanized Coating: This is one of the most popular surface treatments for indoor applications. Galvanizing involves applying a layer of zinc to the steel coil, which provides excellent corrosion resistance and protects the steel from environmental elements. 2. Pre-painted Coating: Pre-painting the steel coil with a specific color or finish is another common surface treatment for indoor applications. This coating not only improves the aesthetics of the steel, but also provides additional protection against corrosion and wear. 3. Powder Coating: Powder coating is a process where a dry powder is electrostatically applied to the steel coil and then cured under heat. This treatment creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder coating is available in a wide range of colors and textures, making it a versatile choice for indoor applications. 4. Vinyl Coating: Vinyl coating is a type of surface treatment that involves applying a layer of PVC (polyvinyl chloride) to the steel coil. This coating provides excellent chemical resistance and protects the steel from moisture, abrasion, and UV radiation. Vinyl coating is commonly used in indoor applications where chemical exposure or moisture resistance is a concern. 5. Laminated Coating: Laminating the steel coil involves bonding a thin layer of plastic or other material to the surface of the steel. This treatment enhances the appearance of the steel and provides additional protection against scratches, stains, and fading. Laminated coatings are available in various colors and patterns, making them suitable for indoor applications where aesthetics is a priority. It is important to consider the specific requirements of the indoor application when choosing a steel coil surface treatment. Factors such as corrosion resistance, durability, aesthetics, and budget should be taken into account to ensure the best possible performance and longevity of the steel coil in indoor environments.

- Q: How are steel coils processed for edge trimming or conditioning?

- Steel coils are processed for edge trimming or conditioning through a series of steps. First, the coils are unwound and fed into a machine that trims the edges to remove any irregularities or imperfections. This process ensures that the edges are smooth and straight. After trimming, the coils may undergo further conditioning, which involves heat treatment or surface coating to enhance their properties and durability. Overall, these processes are essential for producing high-quality steel coils that meet the desired specifications and standards.

- Q: What are the different methods of galvanizing steel coils?

- There are three main methods of galvanizing steel coils: hot-dip galvanizing, electro-galvanizing, and continuous galvanizing. Hot-dip galvanizing involves immersing the steel coil in a bath of molten zinc, providing a thick and durable coating. Electro-galvanizing uses an electrical current to deposit a thin layer of zinc onto the steel surface. Continuous galvanizing is a process where the steel coil is continuously passed through a series of zinc baths, resulting in a uniform coating.

- Q: How are steel coils used in the manufacturing of safety systems?

- Steel coils are commonly used in the manufacturing of safety systems such as airbags and seat belts. The steel coils are formed into springs which provide the necessary tension and force to ensure the proper functioning of these safety devices. The coils are carefully designed and integrated into the system to enhance its performance and reliability, ultimately helping to protect occupants in the event of a collision.

- Q: What are the dimensions of steel coils used in the mining equipment industry?

- The dimensions of steel coils utilized in the mining equipment sector may differ depending on the particular application and demands. Nevertheless, there are frequently employed standard dimensions. Typically, the width of steel coils used in the mining equipment industry can range from 600mm to over 2000mm. This allows for adaptability in the manufacturing process and guarantees that the coils can be customized to fit different equipment sizes and specifications. Regarding thickness, steel coils employed in mining equipment can range from 1.5mm to 20mm or more. The specific thickness is determined by factors such as equipment type, intended usage, and required durability level. The length of steel coils used in the mining equipment industry can also vary, but usually falls within the range of 1000mm to 6000mm. Once again, this offers flexibility in the manufacturing process and ensures that the coils can be cut to suit the exact requirements of the equipment being produced. It is essential to acknowledge that these dimensions are not fixed and can be tailored to meet the specific needs of the mining equipment sector. Manufacturers and suppliers in the industry can often provide coils in different sizes and dimensions to accommodate the wide array of equipment used in mining operations.

- Q: Moravia’s coal and steel industries face challenges because they _____. a.do not run efficientlyb.have run out of resourcesc.have a declining work forced.have not privatized

- do not run efficiently is the correct answer

- Q: Steel, Sturm, and Kitiara are in a series called the Dragonlance Chronicles.

- Steel Brightblade

Send your message to us

Pre-painted Galvanized Steel Coil-EN10169-WOODEN10

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords