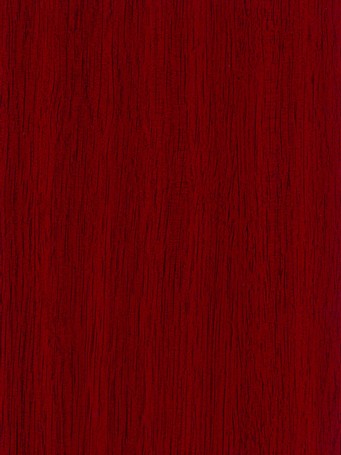

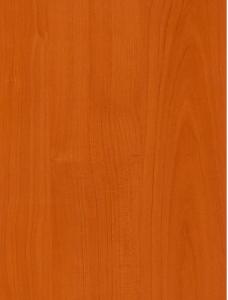

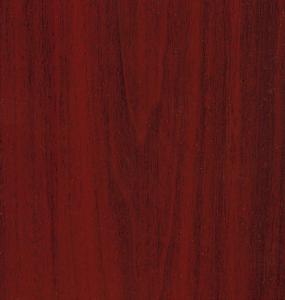

Pre-painted Galvanized Steel Coil-EN10169-WOODEN7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: How are steel coils inspected for color consistency using colorimetry?

- Steel coils can be inspected for color consistency using colorimetry, which is a method of quantifying and measuring colors. Colorimetry involves the use of specialized instruments, such as spectrophotometers or colorimeters, to measure the color of an object in terms of its hue, saturation, and brightness. To inspect steel coils for color consistency, a colorimeter is typically used. This device emits light onto the surface of the steel coil and measures the amount of light reflected back. The reflected light is then analyzed and compared to a known standard color to determine if there are any deviations. The colorimeter measures color by breaking down the reflected light into different wavelengths and quantifying the intensity of each wavelength. This data is then converted into numerical values that represent the color of the steel coil. These numerical values can be compared to a predefined color standard to determine if the color of the coil falls within an acceptable range. To ensure accurate and consistent color measurement, colorimetry relies on standardized color spaces, such as CIE L*a*b* or CIE RGB, which define a specific range of colors. By using these standardized color spaces, colorimeters can provide objective and reliable measurements of color consistency. In the case of steel coils, color consistency is particularly important for industries where the appearance of the final product is crucial, such as automotive or appliance manufacturing. By inspecting the color of steel coils using colorimetry, manufacturers can ensure that the final products have a consistent and visually appealing appearance. Overall, colorimetry is an effective method for inspecting steel coils for color consistency. By using specialized instruments and standardized color spaces, manufacturers can accurately measure and compare the color of steel coils to predefined standards, ensuring that the final products meet the desired color specifications.

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: How are steel coils used in the manufacturing of electrical wiring?

- Steel coils are used in the manufacturing of electrical wiring as a core material for cable reinforcement. The coils provide structural strength and support to the wires, ensuring durability and resistance to external forces. Additionally, the steel coils help in maintaining proper electrical conductivity and minimize electrical losses, ensuring efficient power transmission and distribution.

- Q: How are steel coils transported?

- Steel coils are typically transported using specialized trailers or railway cars. The coils are securely fastened to prevent movement during transportation and are often stacked to maximize space utilization.

- Q: I am doing a experiment on mild steel soaked in sodium chlorideanyone can enlighten me about the effect of the sodium chloride in engineering term ?The mild steel specimen which I soaked in the sodium chloride has orange rust on it

- The mild steel contains a lot of Iron. The NaCl solution quickly attacks the iron content and forms rust. Over time, the solution may also cause what is called 'Chloride Cracking' of the steel. Pitting corrosion of stainless steel due to chlorides would certainly produce a rust-colored product. Passivation can be used to maintain a good corrosion resistant surface of stainless steel process vessel. There are many commercial products for this purpose. In the pharmaceutical industry, this process is often called derouging, that is to remove the buildup of iron oxides on the stainless steel process surfaces

- Q: Can steel coils be stamped?

- Yes, steel coils can be stamped. Stamping is a common manufacturing process used to shape and cut steel coils into desired forms and designs.

- Q: I want an EDC (Every Day Carry) Knife that:~folds~is non-serrated~has a pocket clip~has a blade length of about 4 in. long~is concealable~urban environment friendly~priced around $50What do you suggest? I am currently thinking on purchasing the Cold Steel 4 inch Zytel Ti-Lite.

- Based okorder /

- Q: What's the best way to clean granite countertops and stainless steel appliances? My countertops especially always look dull and streaky. Thanks!!!!!!!

- Granite purely needs a wipe with washing liquid in water Dry off applying a micro fibre textile comparable which comprise your chrome steel yet to maintain it finding extreme high quality practice a splash little one oil on cotton wool and wipe over This facilitates look after its shine and lustre

- Q: Cooling bed generally a part of the steel rolling mills

- In the USA, a steel cooling bed is called a run-out table. It consists of a series of steel rolls. Each roll may be individually driven by an electric motor. DC motors are often used with parallel armatures connected to a common armature voltage control speed control unit. The roll speed is controlled to match the speed of the incoming sheet of steel so that the steel does not slide or skid on the surface of the rolls. Field trim resistors help to assure that the speed and torque of rolls is matched. A centering mechanism may be used to keep the steel in the center of the table. Water may be sprayed from the top and bottom to aid cooling. After an initial run out table, the strip of steel may be cut on-the-fly into individual sheets which pass to another table that is running slightly faster to separate the sheets. Alternatively, the steel may be coiled at the end of the table.

- Q: Okay basically bought my girlfriend Tiffany sterling silver necklace for her birthday and now christmas is coming up i want to buy her this DG Necklace. BUT i have discovered its steel. And its ?110. I am not a rich man i am infact quite young and we have been together for an incredibly long time! I wanted to know is Steel seen as a cheap necklace, whats your say? Don't give me all this bull about her being grateful as she does not expect this. BUT I WANT IT TO BE NICE. Whats your say? Is Steel good? Does it get dirty? Does it shine? Is it worth it? Thanks x

- I think steel would probably be better than silver. (Since silver tarnishes.) I have a piece of steel jewellery and it looks the same as silver. You should definately get her it.

Send your message to us

Pre-painted Galvanized Steel Coil-EN10169-WOODEN7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords