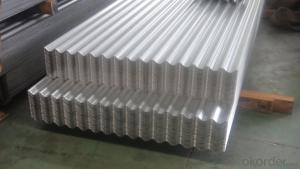

PPGL Steel coils manufacturer Prepainted Galvanzied for roofing,good quality with best price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We have devoted to manufacture steel coils for 13 years. As the biggest manufacture in Hebei China, we have two large factory and 8 production lines, sincerely welcome to your visit if possible.

1, Production Introduction: PPGI are prepainted galvanized steel coils, used for making roof, advantage is can be used at least 10 years.

2, Product feature:

① We're factory, products has the best price for you.

② We have 8 production lines, have the fastest delivery time for order

③ All colors can be produced by our factory.

④ Product can accept any test before shipment.

3,Parameter list:

① Product Name:PPGL

②Thickness:0.2-1.0MM

③ Width:914-1250MM

④ Az Coating:30-275 G/M2

⑤Coil Weight:3-5MT

⑥Coil ID:508MM

⑦Packing :Standard Export Seaworthy Shipping Packaging

⑧Payment Terms:T/T Or irrevocable LC at sight

⑨Delivery Time:

10 days after advance is confirmed if order≤100MT

15 days after advance is confirmed if 100MT≤order≤200MT

20 days after advance is confirmed if 200MT≤order

4,

- Q: Can steel sheets be used for interior design purposes?

- Yes, steel sheets can be used for interior design purposes. Steel sheets have a sleek and modern appearance that can add an industrial or contemporary touch to any interior space. They are durable, long-lasting, and resistant to wear and tear, making them suitable for high-traffic areas. Steel sheets can be used in various ways in interior design, such as wall cladding, ceiling panels, room dividers, furniture, countertops, and backsplashes. They can be painted or coated in different finishes to match the desired aesthetic, and can also be shaped or perforated to create unique patterns or textures. Overall, steel sheets offer versatility, strength, and a visually appealing element to interior design projects.

- Q: Can the steel sheets be used for storage cabinets?

- Yes, steel sheets can be used for storage cabinets. Steel is a durable and sturdy material that is commonly used in the construction of cabinets and other storage solutions. Steel sheets can be easily fabricated and shaped into the desired size and design for cabinets, providing a strong and reliable storage solution. Additionally, steel is resistant to corrosion, making it suitable for storing various items and ensuring the longevity of the cabinets.

- Q: Are the steel sheets magnetic?

- Indeed, steel sheets possess magnetism. Being predominantly constituted of iron, steel qualifies as a ferromagnetic substance. Consequently, it can be subjected to magnetization and exhibit an attractive force towards other materials with magnetic properties. Steel sheets are frequently employed in contexts necessitating magnetic characteristics, such as the production of magnets, electrical devices, and diverse industrial machinery.

- Q: What are the different methods of joining steel sheets?

- There are several methods of joining steel sheets, including welding, riveting, bolting, adhesive bonding, and clinching.

- Q: How do steel sheets handle water resistance?

- Steel sheets handle water resistance very well due to their inherent properties. Steel is a non-porous material, meaning it does not absorb water. Additionally, steel sheets are often coated with protective layers, such as galvanized or stainless steel finishes, which provide an extra barrier against water penetration. This makes steel sheets highly resistant to corrosion, rust, and water damage, making them suitable for various applications, including roofing, construction, and marine environments.

- Q: Can the steel sheets be used for industrial machinery?

- Industrial machinery can indeed utilize steel sheets. Steel, known for its robustness, endurance, and resistance to damage, is a favored option for constructing industrial machinery. By shaping, cutting, and welding steel sheets, manufacturers can produce diverse components and parts essential for industrial machinery. The adaptability of steel empowers manufacturers to design and fabricate machinery that precisely meets specifications and demands. Furthermore, steel's capacity to endure hefty burdens, extreme temperatures, and corrosive surroundings renders it suitable for a vast array of industrial applications.

- Q: What is the typical thermal conductivity of a steel sheet?

- The typical thermal conductivity of a steel sheet is around 50-60 W/mK.

- Q: What are the applications of steel sheets in construction?

- Steel sheets are widely used in construction for applications like roofing, flooring, wall cladding, and structural components due to their durability, strength, and versatility. They provide a reliable and long-lasting solution for various construction needs, ensuring stability, fire resistance, and protection against harsh weather conditions. Additionally, steel sheets can be easily customized, allowing for flexibility in design and construction processes.

- Q: Can steel sheets be used for HVAC systems?

- Yes, steel sheets can be used for HVAC systems. Steel sheets are commonly used in HVAC systems for ductwork fabrication and construction due to their durability, strength, and resistance to corrosion. They are able to withstand high temperatures, making them suitable for heating systems, and can also be used in air conditioning systems for ducts, plenums, and vents.

- Q: What is the typical price difference between galvanized and non-galvanized steel sheets?

- The price difference between galvanized and non-galvanized steel sheets typically fluctuates based on various factors, including the steel grade, market conditions, and the size and quantity of the sheets. Generally, non-galvanized steel sheets are slightly less expensive than galvanized ones. Galvanization is a process that involves applying a protective zinc coating to the steel, which helps prevent rust and corrosion. This extra layer of protection enhances the steel's durability and lifespan, making it suitable for outdoor use or in environments exposed to moisture or chemicals. The cost of galvanizing steel includes additional manufacturing steps, such as cleaning, dipping the steel in molten zinc, and post-treatment processes. These additional steps contribute to the higher price of galvanized steel sheets compared to their non-galvanized counterparts. As a rough estimate, the price difference between galvanized and non-galvanized steel sheets can range from 10% to 30%. However, it's important to note that this is a general range, and actual prices may vary depending on the specific market conditions and supplier pricing. To obtain accurate and up-to-date pricing information for galvanized and non-galvanized steel sheets in your specific region or market, it is advisable to consult with steel suppliers or conduct market research.

Send your message to us

PPGL Steel coils manufacturer Prepainted Galvanzied for roofing,good quality with best price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords