Pre-Painted Galvanized Steel Sheet/Coil in High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

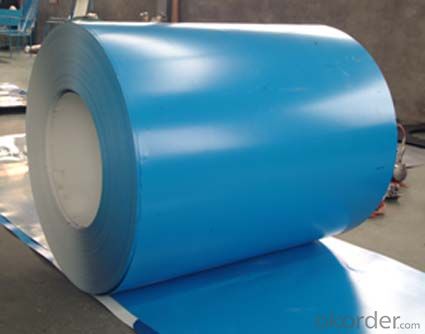

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets withstand high temperatures?

- Yes, steel sheets can withstand high temperatures.

- Q: What are the different sheet metal folding techniques for steel sheets?

- Steel sheets can be subjected to various sheet metal folding techniques. These techniques find extensive application in industries like automotive, aerospace, and construction for creating intricate shapes and structures. Some frequently used sheet metal folding techniques for steel sheets comprise: 1. Box and Pan Folding: This technique entails bending the sheet metal along multiple parallel edges to form a box-shaped structure. It is commonly utilized for manufacturing enclosures, cabinets, and trays. 2. Hemming: Hemming is employed to fold the edges of a sheet metal component, enhancing its rigidity and eliminating sharp edges. It finds prominent usage in the automotive sector for fabricating panels and body parts. 3. Brake Press Folding: Brake press, a machine tool utilizing hydraulic or mechanical press, is employed to bend the sheet metal. Precise and accurate folding is facilitated by adjusting the bend's angle and depth. Brake press folding is a frequently employed technique in sheet metal fabrication. 4. Roll Forming: Roll forming is a continuous bending process wherein the sheet metal passes through a series of rollers, gradually shaping it into the desired profile. It is suitable for creating elongated and continuous shapes like tubes and channels. 5. Rotary Folding: In this technique, a rotating tool is utilized to fold the sheet metal along a curved or circular path. It is often applied to create rounded edges, curves, and cylindrical shapes. 6. Folding Machines: Folding machines are specifically designed to fold sheet metal by applying pressure along a predetermined line. These machines can be programmed to carry out various folding operations, including simple bends, complex shapes, and multiple folds. Each of these sheet metal folding techniques possesses its own advantages and limitations. The selection of a particular technique depends on factors such as the design's complexity, required precision, and production volume. Skilled craftsmen and specialized machinery are frequently employed to ensure accurate and efficient folding of steel sheets.

- Q: What does "Z" mean to the performance of steel?

- To apply for Z steel plate thickness and subjected to tensile load on just the thickness direction has the performance requirements, it is in a certain level of structural steel (called parent steel) on the basis of the special treatment (such as calcium treatment, vacuum degassing, argon stirring etc.) and proper heat treatment steel.

- Q: Can steel sheets be used for decorative column wraps?

- Indeed, decorative column wraps can be created using steel sheets. The versatility of steel sheets allows for easy customization to cater to different design preferences. Whether one desires a sleek and modern look or a more intricate and ornate design, steel sheets can be shaped accordingly. To further enhance the aesthetic appeal and protect against corrosion, steel sheets can be painted or coated with various finishes. Moreover, steel is a durable and long-lasting material, making it suitable for both indoor and outdoor applications. Thus, if one aims to add a contemporary touch or a traditional charm to their space, steel sheets serve as an excellent option for decorative column wraps.

- Q: How do steel sheets perform in corrosive environments like saltwater?

- Steel sheets exhibit excellent resistance to rust and corrosion in corrosive environments like saltwater. This is primarily due to the presence of chromium in the steel, which forms a protective layer of chromium oxide on the metal surface. This layer acts as a barrier, preventing direct contact between the steel and the corrosive elements in saltwater, thereby reducing the risk of corrosion. However, it is important to acknowledge that steel sheets are not completely immune to saltwater corrosion. Extended exposure to saltwater can still lead to some degree of corrosion, particularly when combined with other factors such as high temperatures, abrasion, or impurities in the water. To enhance the performance of steel sheets in saltwater environments, various protective coatings can be utilized. These coatings, including paint, galvanization, or epoxy, provide an extra layer of protection to the steel, further minimizing the chances of corrosion. Regular maintenance and inspection are vital to ensure the long-term effectiveness of steel sheets in saltwater environments. This involves cleaning the surface, eliminating any accumulated salt or debris, and rectifying any damaged or compromised areas of the protective coating. Overall, although steel sheets possess good resistance to corrosion in saltwater environments, it is imperative to take appropriate precautions such as using protective coatings and conducting regular maintenance to ensure their optimal performance and durability.

- Q: Are steel sheets suitable for electrical grounding applications?

- Yes, steel sheets can be suitable for electrical grounding applications. Steel is a good conductor of electricity, and it can effectively dissipate electrical charges to the ground. Steel sheets are commonly used in grounding applications because of their durability, strength, and cost-effectiveness. They can be easily installed and provide a reliable connection to the earth, ensuring a safe path for electrical currents to flow in case of a fault or surge. However, it is important to ensure that the steel sheets are properly installed and maintained, as any corrosion or damage can affect their conductivity and effectiveness in grounding electrical systems.

- Q: Can steel sheets be used for electrical enclosures or cabinets?

- Yes, steel sheets can be used for electrical enclosures or cabinets. Steel is a commonly used material for such applications due to its durability, strength, and ability to provide protection against external factors like moisture and impact. Additionally, steel can be easily modified or customized to meet specific requirements, making it suitable for various electrical enclosure designs.

- Q: Can the steel sheets be used as a magnetic surface?

- Yes, steel sheets can be used as a magnetic surface.

- Q: Can the steel surface be made of epoxy resin flooring?

- According to the characteristics of epoxy resin, it should be possible

- Q: What are the different coating options available for steel sheets?

- There are several coating options available for steel sheets, including galvanized coating, zinc coating, epoxy coating, powder coating, and paint coating. Each option provides different benefits such as corrosion resistance, durability, aesthetic appeal, and ease of maintenance. The choice of coating depends on the specific requirements of the application and the desired outcome.

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil in High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords