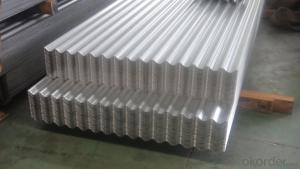

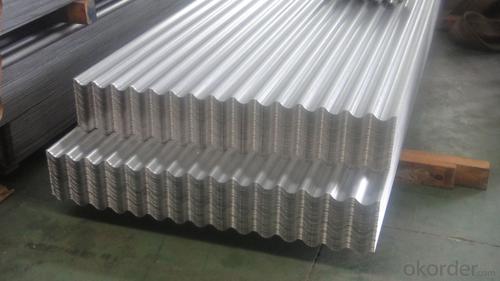

galvanized metal roofing prices / galvanized steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized corrugated sheet / Steel iron corrugated plate

1) Standard: ASTM, GB, JIS

2) Grade: SGCC/DX51D/SGCH

3) Specification: Thickness: 0.13-0.5mm

Width: 665mm--914mm

Length: 1000mm-3660mm

4) Application: Roof and wallboards Wallboards, ceiling boards, window panel

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

Grade | SGCC, DX51D, DX53D, DX54D, etc |

Thickness | 0.15-1.2mm |

Effective Width | After Briquetting: 790-1025mm |

Waves | 8-15 |

Length | 1000-6000mm |

Zinc Coating | 60g/m2-180g/m2 |

Spangle State | regular spangle, small spangle, big spangle, non-spangle |

Color | According to your requirements. |

- Q: What is the typical thickness tolerance of a steel sheet?

- The typical thickness tolerance of a steel sheet can vary depending on the specific grade of steel and the manufacturing process used. However, in general, the typical thickness tolerance for a steel sheet is around ±0.005 to ±0.010 inches.

- Q: What is the difference between a hot rolled and pickled steel sheet?

- The production of a hot rolled steel sheet involves heating the steel above its recrystallization temperature, typically around 1700°F (926°C), and then rolling it into the desired shape or thickness. This process leads to the formation of a scale or oxide layer on the surface of the steel. In contrast, a pickled steel sheet goes through an additional step known as pickling, which removes the scale or oxide layer formed during the hot rolling process. This step is usually carried out by immersing the steel sheet in an acid bath, such as hydrochloric acid, to dissolve the scale. The main distinction between a hot rolled and pickled steel sheet lies in the surface finish and cleanliness. Due to the presence of scale, a hot rolled steel sheet will have a rougher surface, which may not be visually appealing and might require further processing or finishing. On the other hand, a pickled steel sheet will exhibit a smoother and cleaner surface as a result of the scale removal. Another difference lies in the corrosion resistance of the two types of steel sheets. Hot rolled steel, with its scale, is more prone to corrosion, especially in humid or corrosive environments. Conversely, pickled steel possesses better corrosion resistance due to the elimination of the scale and the subsequent application of a protective coating or treatment. Regarding applications, hot rolled steel sheets are commonly used in structural components, construction materials, and general fabrication where surface finish is not a critical factor. In contrast, pickled steel sheets are often preferred in industries such as automotive, appliances, and manufacturing, where a smooth and clean surface is desired for further processing or finishing. In summary, the difference between a hot rolled and pickled steel sheet lies in the surface finish, cleanliness, and corrosion resistance. While hot rolled steel has a rougher surface due to the presence of scale, pickled steel undergoes an acid bath to remove the scale, resulting in a smoother and cleaner surface. Pickled steel also offers better resistance to corrosion and is preferred in applications where a high-quality surface finish is required.

- Q: What are the specifications for steel sheets used in construction?

- The specifications for steel sheets used in construction can vary depending on the specific project requirements. However, common specifications generally include the steel grade (such as ASTM A36 or ASTM A572), the thickness (measured in gauge or millimeters), the width and length dimensions, the surface finish (such as hot rolled or cold rolled), and any additional properties like corrosion resistance or fire resistance. These specifications ensure that the steel sheets meet the necessary strength, durability, and safety standards for their intended use in construction applications.

- Q: How do steel sheets compare to glass sheets?

- Different applications require distinct characteristics in steel sheets and glass sheets. To begin with, steel sheets are renowned for their strength and durability, enabling them to bear heavy loads and resist impact and damage effectively. Consequently, they are well-suited for construction purposes, including building manufacturing, bridge construction, and machinery development. Furthermore, steel sheets provide excellent fire protection and can withstand extreme weather conditions. On the other hand, glass sheets are highly valued for their transparency and aesthetic appeal. By allowing natural light to pass through, they create a bright and open atmosphere. Consequently, glass sheets are commonly used in windows, doors, and architectural structures to enhance visibility and the visual appeal of a space. Additionally, glass sheets possess excellent thermal insulation properties, which aid in reducing energy consumption in buildings. When it comes to maintenance, steel sheets require minimal upkeep due to their corrosion resistance and infrequent need for cleaning. However, they may require painting or protective coatings to prevent rusting. Conversely, glass sheets may need regular cleaning to maintain their transparency and appearance. Moreover, they are more prone to scratching and breakage compared to steel sheets. Lastly, cost must be considered. Generally, steel sheets have a lower initial cost compared to glass sheets. However, the overall cost may vary depending on factors such as size, thickness, and quality. Additionally, the installation and maintenance costs should also be taken into account. In conclusion, steel sheets and glass sheets possess unique characteristics and properties. The choice between the two depends on specific project requirements, including strength, transparency, aesthetics, maintenance, and cost considerations.

- Q: Can the steel sheets be used for outdoor furniture?

- Outdoor furniture can indeed utilize steel sheets. Steel, being a robust and weather-resistant substance, is well-suited for outdoor purposes. It can withstand diverse environmental conditions, including rain, wind, and sunlight, without rapid corrosion or deterioration. Moreover, steel sheets can be manipulated and formed into various furniture styles, offering both practicality and visual allure. Whether it's tables, chairs, benches, or even decorative accents, steel sheets prove to be an exceptional option for outdoor furniture due to their durability, longevity, and adaptability.

- Q: What are the different quality standards for steel sheets?

- There are several different quality standards for steel sheets, which are used to ensure that the material meets specific requirements and is suitable for its intended use. Some of the most common quality standards for steel sheets include: 1. ASTM A36/A36M: This standard specifies the requirements for carbon structural steel, including steel sheets, used in general structural purposes. It outlines the chemical composition, mechanical properties, and other relevant factors. 2. ASTM A568/A568M: This standard covers the general requirements for steel sheet products, including hot-rolled, cold-rolled, and coated sheets. It provides specifications for dimensions, tolerances, and surface quality. 3. EN 10130: This European standard specifies the requirements for cold-rolled low carbon steel flat products, including steel sheets. It outlines the chemical composition, mechanical properties, and other relevant factors. 4. JIS G 3302: This Japanese industrial standard covers the requirements for hot-dip zinc-coated steel sheets and coils. It includes specifications for the coating weight, surface finish, and mechanical properties. 5. ISO 3574: This international standard specifies the requirements for cold-reduced carbon steel sheet of commercial and drawing qualities. It provides guidelines for dimensions, tolerances, and mechanical properties. 6. GB/T 2518: This Chinese national standard outlines the requirements for continuous hot-dip zinc-coated steel sheets and coils. It includes specifications for the coating weight, surface finish, and mechanical properties. These quality standards help ensure that steel sheets are produced and supplied with consistent properties and characteristics, making them suitable for various applications such as construction, automotive, manufacturing, and more. It is important for manufacturers, suppliers, and end-users to adhere to these standards to ensure the quality and reliability of steel sheet products.

- Q: Are steel sheets resistant to abrasion?

- Yes, steel sheets are generally resistant to abrasion. They are known for their durability and ability to withstand wear and tear, making them suitable for applications where abrasion resistance is required.

- Q: What is the average thickness of galvanized steel sheets?

- The average thickness of galvanized steel sheets typically ranges from 0.8mm to 3mm, depending on the specific application and industry standards.

- Q: Is 5mm thick steel plate tapping M8 thread reliable?

- The pitch of the M8 is 1.25, it can attack 4 teeth. The force of the thread is 4-5 teeth. The bottom is not greater than 6.7mm, 8.8 plus elastic pad bolt.

- Q: Are steel sheets suitable for manufacturing kitchen appliances?

- Yes, steel sheets are suitable for manufacturing kitchen appliances. Steel is a versatile and durable material that is commonly used in the manufacturing industry. It has high strength, which makes it suitable for withstanding the daily wear and tear of kitchen appliances. Steel sheets are also resistant to corrosion, which is important in a kitchen environment where appliances are constantly exposed to water, moisture, and food spills. Additionally, steel is a hygienic material that is easy to clean and maintain, making it ideal for kitchen appliances where cleanliness is crucial. Furthermore, steel sheets can be easily shaped and formed into different designs and sizes, allowing for a wide variety of kitchen appliances to be manufactured. Overall, steel sheets provide the necessary properties and characteristics required for the manufacturing of kitchen appliances.

Send your message to us

galvanized metal roofing prices / galvanized steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords