PPGI Prepainted Galvanized Steel Roof Sheets in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Details of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Grade | DX51D, SGCC, CGCC |

Thickness | 0.15mm-1.5mm |

Width | 600mm-1500mm(914/1219/1250 are available) |

Standard | JIS G3312, ASTM,GB/T1275 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Length | As per requests |

Zinc Coating | 40g-275g/m2 |

Lacquer Coated | 20-25 microns/5-15 microns |

Coil ID | 508mm/610mm |

Coil Weight | normally 3-10mt or as your requirement |

Supply ability | 200,000Mt/year (MOQ:25Mt) |

Color | RAL No. |

Price terms | FOB,CFR,CIF |

Payment terms | L/C,T/T |

Deliver time | 30days after received deposit or L/C |

Packing | Standard exporting package |

steel strip Water proof paper, metal covers, | |

Application | Corrugated roofing,outside building, |

boating building,car producing | |

household appliance | |

Main market | Southeast Asia , the EU, Russia, Ukraine , Latin America and other countries and Regions |

Specification of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Thickness | Width | Length of plate | Inner diameter of coil |

0.18-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass: | |||

Available Coated Mass(g/m^2) | Base plate | Available Coated Mass(g/m^2) | |

60,80, 100, 120, 160, 180 | Galvanized Steel | 60,80, 100, 120, 160, 180 | |

50, 70, 150 | Galvalume Steel | 50, 70, 150 |

Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20±5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface |

|

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coatin | Primer coating + Finish back coating | 2/2 | |

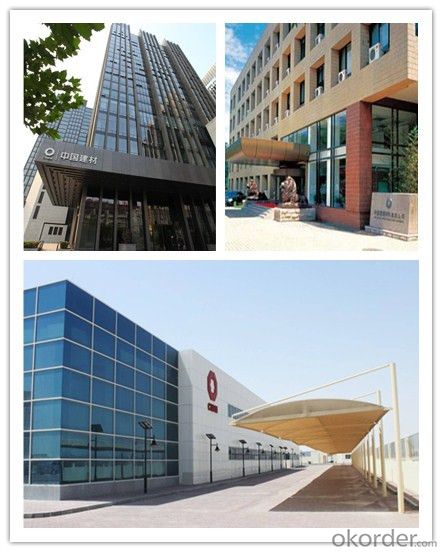

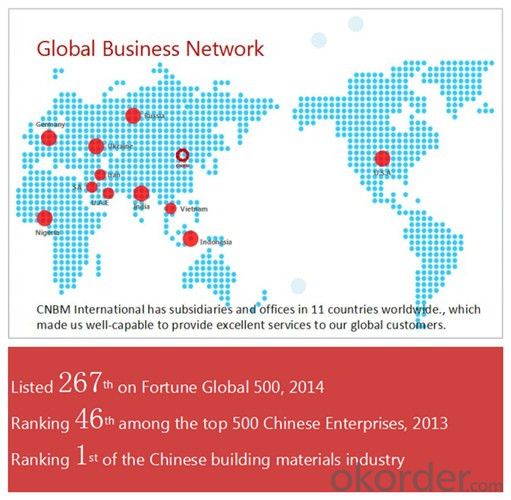

CNBM Introduction of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

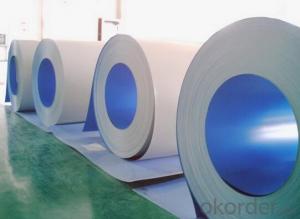

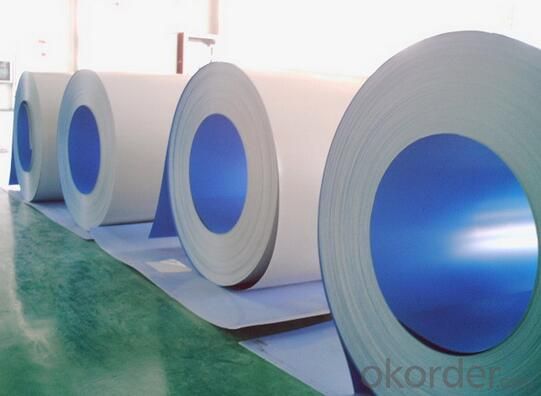

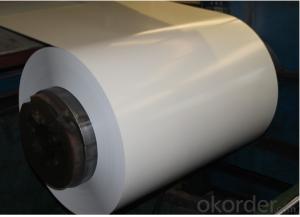

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the specific requirements for special steel used in the oil and gas sector?

- The specific requirements for special steel used in the oil and gas sector are primarily focused on its ability to withstand harsh and demanding environments. Some of the key requirements include: 1. Corrosion Resistance: Special steel used in the oil and gas sector must have excellent resistance to corrosion caused by various factors such as moisture, chemicals, and high temperatures. This ensures the longevity and reliability of the equipment in corrosive environments. 2. High Strength: The steel must possess high strength and toughness to withstand the extreme pressure, stress, and load conditions experienced in oil and gas operations. This is crucial for ensuring the structural integrity of equipment like pipelines, offshore platforms, and drilling components. 3. Low Temperature Resistance: Oil and gas operations often involve working in extremely low-temperature conditions, especially in deep-sea exploration or Arctic regions. Special steel used in such applications must have good low-temperature toughness to prevent brittle fracture and maintain its mechanical properties. 4. Weldability: Special steel used in the oil and gas sector should exhibit good weldability to ensure ease of fabrication and construction. This is crucial for joining various components and pipelines together, ensuring structural integrity and minimizing the risk of failure. 5. Resistance to Hydrogen-Induced Cracking (HIC): In the presence of hydrogen sulfide gas, which is common in many oil and gas environments, special steel must have resistance to hydrogen-induced cracking. HIC can lead to catastrophic failures, so the steel must be specifically designed to prevent this phenomenon. 6. Sour Service Resistance: In certain oil and gas fields, the presence of hydrogen sulfide and other corrosive gases necessitates the use of special steel that can withstand sour service conditions. The steel must have high resistance to sulfide stress cracking and exhibit good mechanical properties under these harsh conditions. 7. Compliance with Industry Standards: Special steel used in the oil and gas sector must meet specific industry standards and specifications, such as those set by the American Petroleum Institute (API), to ensure quality, reliability, and safety. Overall, the requirements for special steel used in the oil and gas sector are driven by the need for durability, reliability, and safety in challenging operating environments. These requirements may vary depending on the specific application within the industry, but they are all critical for ensuring the smooth and efficient functioning of oil and gas operations.

- Q: What are the main advantages of using special steel in the aerospace industry?

- The main advantages of using special steel in the aerospace industry are its high strength-to-weight ratio, excellent corrosion resistance, and superior heat and wear resistance. These properties make special steel ideal for constructing aircraft components that need to withstand extreme conditions, such as high temperatures, pressure, and stress. Additionally, special steel offers excellent fatigue resistance, ensuring the longevity and reliability of aerospace structures.

- Q: What are the properties of case-hardening steel?

- Case-hardening steel is a type of steel that possesses specific properties, such as high surface hardness and improved wear resistance. It achieves these properties through a process called case hardening, which involves heating the steel to a specific temperature and then introducing a carbon-rich environment. This process allows the steel to absorb carbon atoms, resulting in a hardened outer layer while maintaining a tough and ductile core. The hardened surface layer provides excellent resistance to abrasion and impact, making case-hardening steel suitable for applications requiring durability and strength, such as gears, shafts, and bearings.

- Q: How does special steel perform in high-pressure hydrogen environments?

- Special steel performs well in high-pressure hydrogen environments due to its high strength, corrosion resistance, and ability to withstand hydrogen embrittlement. It offers reliable performance and minimizes the risk of hydrogen-induced failures, making it a suitable choice for applications such as hydrogen storage, transportation, and fuel cells.

- Q: How does special steel perform in marine environments?

- Special steel is specifically designed to withstand the harsh conditions of marine environments. It offers superior corrosion resistance, high strength, and excellent durability, making it highly suitable for applications in marine settings. This type of steel can effectively resist the corrosive effects of saltwater, moisture, and other environmental factors, ensuring long-term performance and reducing maintenance requirements.

- Q: What are the different methods for improving the toughness of special steel?

- There are multiple approaches that can be utilized to enhance the toughness of special steel. Among the most effective techniques is the utilization of alloying. By incorporating specific elements like nickel, chromium, or molybdenum into the steel composition, the toughness can be greatly enhanced. These alloying elements aid in increasing the strength and resistance to cracking and fracture. Another method involves employing heat treatment processes. For instance, one can utilize quenching and tempering to improve the toughness of the steel. Quenching entails rapidly cooling the steel from a high temperature to room temperature, resulting in a hardened structure. Subsequently, tempering takes place, where the steel is reheated to a precise temperature and then slowly cooled. This process helps alleviate internal stresses and enhance the toughness of the steel. Furthermore, refining the microstructure of the steel can also amplify its toughness. Techniques like grain refinement, which encompass reducing the size of the grains in the steel, can lead to improved toughness. This is due to the fact that smaller grains hinder the propagation of cracks, making the steel more resistant to fracture. Lastly, special steel can undergo processes such as shot peening or surface hardening to augment its toughness. Shot peening involves bombarding the steel's surface with tiny metallic or ceramic particles, inducing compressive stresses and enhancing resistance to crack initiation. Surface hardening techniques like carburizing or nitriding can generate a hardened layer on the steel's surface, increasing its toughness and wear resistance. In conclusion, the various methods for enhancing the toughness of special steel encompass alloying, heat treatment processes, microstructure refinement, and surface treatments. Each of these techniques can be customized to meet the specific requirements of the steel and achieve the desired level of toughness.

- Q: How is leaded steel used in machining operations?

- Leaded steel is commonly used in machining operations due to its improved machinability. The addition of lead to the steel composition enhances its ability to be cut, drilled, and shaped with ease, reducing tool wear and improving surface finish. This type of steel is particularly useful in high-speed machining applications, where efficiency and precision are crucial.

- Q: How does special steel perform in cutting applications?

- Special steel is highly regarded for its exceptional performance in cutting applications. Due to its unique composition and properties, special steel exhibits superior strength, hardness, and wear resistance compared to regular steel. These characteristics make it incredibly effective in withstanding the intense forces and pressures involved in cutting processes. Special steel is known for its ability to maintain its shape and sharpness even under extreme conditions. It has a high level of toughness, ensuring that it can withstand repeated impact and resist deformation or breakage. This durability allows it to maintain its cutting edge for an extended period, resulting in longer tool life and reduced downtime for sharpening or replacing blades. Furthermore, special steel's hardness enables it to effectively cut through tough and abrasive materials such as metals, alloys, and composites. It can withstand the heat generated during cutting, preventing the blade from becoming dull or losing its cutting ability. This heat resistance also reduces the risk of thermal damage to the workpiece, ensuring precise and clean cuts. In addition to its mechanical properties, special steel offers excellent corrosion resistance. This is particularly advantageous in cutting applications that involve exposure to moisture, chemicals, or corrosive environments. The corrosion resistance ensures that the cutting tools made from special steel maintain their performance and longevity, even in challenging conditions. Overall, special steel exhibits exceptional performance in cutting applications due to its superior strength, hardness, wear resistance, and corrosion resistance. Its ability to maintain a sharp cutting edge, withstand high pressures and temperatures, and resist corrosion makes it a preferred choice in various industries, including manufacturing, construction, automotive, and aerospace.

- Q: What are the main factors that affect the machinability of special steel?

- The main factors that affect the machinability of special steel include the steel's chemical composition, microstructure, hardness, and the presence of impurities or non-metallic inclusions. Additionally, factors such as cutting tool material, cutting speed, feed rate, and coolant usage also influence machinability.

- Q: What are the main characteristics of pressure vessel steel forgings?

- The main characteristics of pressure vessel steel forgings include high strength, excellent durability, enhanced resistance to corrosion and wear, and the ability to withstand high pressure and temperature conditions. These forgings are typically made from low-alloy or carbon steel and undergo a forging process to improve their mechanical properties and ensure uniformity. Additionally, pressure vessel steel forgings are extensively tested for quality assurance to ensure their reliability and safety in various industrial applications.

Send your message to us

PPGI Prepainted Galvanized Steel Roof Sheets in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords