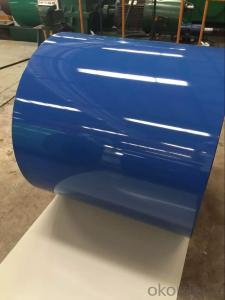

PPGI/Color Coated Steel for Roofing/Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

From China Manufacturer PPGI/PPGL Prepainted Galvanized Steel For Building Steel Material / Roofing

1) Price terms: CIF CFR FOB

2) Payment: T/T or L/C at sight

3) Shipping port: Qingdao China

4) Samples are available and free of charge

5) Coil ID : 508 / 610 MM

6) Packing: seaworthy packing

7) Delivery: about 10-15 days upon the day of deposit and L/C opening

Product | PPGI/PPGL | Galvanized | Galvalume/Aluzinc | |

Certificate | ISO9001:2008,ISO14001:2004 | |||

standard | ASTM A755 | ASTM A653 | ASTM A792 | |

Grade | CGCC/CGLCC | SGCC/CS/DX51D | SGLCC/CS/DX51D | |

Model | Thick:0.16-0.90mm | Thick:0.14-3.5mm | Thick:0.23-2.0mm | |

Type | Roll/Coil | Roll/Coil | Roll/Coil | |

surface | Protective | Chromating Treatment Oiled | ||

Application | Structural,Roofing,Commercial use,Household Appliance,Industry | |||

Special | Wear resistant steel,High-strength-steel plate | |||

FAQ

1. Is the sample available?

Yes, samples can be sent for test if you need.

- Q: What are the common applications of stainless steel coils?

- Stainless steel coils have numerous applications in various industries due to their exceptional corrosion resistance, durability, and versatility. Some common applications include manufacturing of kitchen appliances, automotive parts, construction materials, medical instruments, chemical processing equipment, and electrical components. Additionally, stainless steel coils are widely used in the production of pipes, tubes, and fittings for various sectors such as oil and gas, food processing, pharmaceuticals, and water treatment.

- Q: How are steel coils used in the manufacturing of pipes?

- Steel coils are used in the manufacturing of pipes by being uncoiled and fed into a pipe-making machine. The steel is then shaped and welded to form a continuous pipe, which is cut and shaped to the desired length and diameter.

- Q: How are steel coils tested for quality?

- Steel coils are tested for quality through a variety of methods including visual inspection, dimensional measurements, chemical composition analysis, and mechanical testing. These tests ensure that the steel coils meet the required standards for strength, durability, and other performance parameters.

- Q: i was giving this old knive. the knife part is stainless steel and has a couple rust spots but im not sure that the handle is (i think stainless) but it has this un smooth surface i dont think its rust because its not brown. would rubbing alcohol help clean it?

- Your answers are all good but I would mention that we have a set of Sabtier chef knifes that were expensive these look to be stainless but are not quite as I think that marine grade stainless does not make the best cutting edge and my guess is that your knife would contain a greater amount of carbon better cutting edge but not so stainless. As a carpenter that has to sharpen cutting tools I add that I have never had a chisel or plane blade that was made of stainless steel and the best edges I obtain are with vintage tools. Bar Keepers friend is great as is 00 grade wire wool but do not put your knife through the dishwasher as the cleaning tabs will pit the surface of your knife.

- Q: How are steel coils inspected for edge quality using visual inspection?

- Steel coils are inspected for edge quality using visual inspection by carefully examining the edges of the coils for any defects, such as cracks, burrs, or unevenness. Trained inspectors visually assess the edges for any visible abnormalities or irregularities, ensuring that the edges meet the required quality standards for further processing or usage.

- Q: How are steel coils processed?

- Steel coils are processed through a series of steps that include uncoiling, levelling, cutting, and recoiling, ensuring the steel is transformed into the desired shape and size for various applications such as construction, automotive, and manufacturing industries.

- Q: How are steel coils used in the manufacturing of agricultural irrigation systems?

- Steel coils are used in the manufacturing of agricultural irrigation systems as they are shaped and formed into pipes, tubes, or other components that are essential for transporting water from the source to the fields. The coils provide strength, durability, and corrosion resistance, ensuring that the irrigation system can withstand the harsh agricultural environment and last for a long time.

- Q: I need to know the density of steel as one of my physical properties of steel. Any answers? If u have more physical or chemical properties of steel, that would help to thanks.

- It depends on what kind of steel it is. Martensitic steel has a lower density than austenitic steel. However, a good number for a typical steel is 0.286 pounds per cubic inch (7.92 grams per cubic centimeter).

- Q: I'm quite confused...i watched all of steel angel kurumi (the 28 episodes) and then continued to steel angel kurumi zero. it was an entire different story line with only the steel angels being the same. the world is different the guys are different, and there is a new character. Even the humor is gone. its like a whole different series. So what gives, what is the relationship between them?

- Steel Angel Zero is an OVA (Original Video Animation), a very short animation that went straight to DVD. It probably was written because Kurumi was so popular, and the producer wanted to check the waters for whether they should make a second season. It's pretty hard to keep track of what anime is which, especially in the more popular series. If you think Zero is worth zero, try Steel Angel Kurumi 2 (anime, 12 episodes), and Steel Angel Kurumi Encore (OVA, 4 episodes) as well.

Send your message to us

PPGI/Color Coated Steel for Roofing/Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords