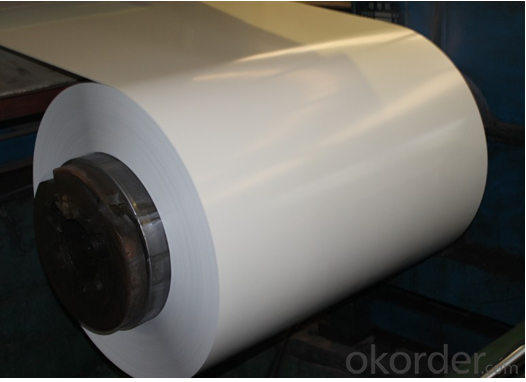

Pre-painted Galvanized Steel Coil/China PPGI for Roof Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coil/China PPGI for Roof Sheet

Product Description

CNBM Steel Plate Co., Ltd. is a large-scale private enterprise, specialized in producing and selling colored steel coils,PPGI, PPGI for Roof and Clad ,PPGL,GL and GI. We have our own R & D group.

Product Description

NAME: Competitive PPGI for Roof and Clad

SIZE:

Thickness: 0.12-1.5mm

Width: 600mm,750mm,762mm,900mm,914mm,940mm,1000mm,1050mm, 1090mm,1100mm,1200mm, 1219mm, 1250mm,1250mm

Length: According to the customer's request

Hardness:Soft( around HRB 65) ,full hard (HRB90-95)

Strength of Extension: more than 300Mpa

Yield Strength:370-380Mpa

Thickness tolerance: +/-0.02 mm(0.01 as you requested)

Width tolerance:+/ -2.0mm

ZINC, PAINT & COLOR:

Zinc coating: 30-275G/M2

Paint thickness: Top 15-25um + Back 8-10um

Paint: Epoxy Polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester

Color: As the RAL color standard or customer's sample

PACKING:

Coil weight: 3-5tons

ID: 508mm\610mm

Standard sea worthy package

STANDARD:

JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB

Base mental: Hot galvanized steel,SGCC,SPCC,SPHC, DX51D+Z, Q195,etc

Quality: CQ,DQ,DX51D

Lifespan: 10-15 years

APPLICATION:

it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

Base mental | hot galvanized steel |

Thickness | 0.12-1.5mm |

Width | 600-1500mm |

Coil Weight | 3-5ton |

Quality: | DX51D DQ CQ |

Color | all RAL colors or as per customers' sample |

Zinc-coating | 30g/m2-275g/m2 |

Coil ID | 508mm-610mm |

Packing | standard seaworthy package |

Technique | cold rolled, hot-dipped galvanizing, color coated |

Painting | Top and bottom: 20mic+5mic RMP |

Tolerance | Thickness: +/-0.02mm |

Description | Pre-painted Steel Coil uses hot galvanized steel as its basic material, factory adopts advanced equipment to degrease, rinse, transform the galvanized steel, then make primary and refined lavation to the steel coils. |

application | They are mainly applied for steel structure buildings, household appliance, furniture, transportation and other industries |

feature | Pre-painted Steel Coils have excellent performance of decoration, corrosion resistance etc. |

The special order can be negotiated | |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

4. Is the sample available?

Yes, samples can be sent for test if you need.

- Q: Can steel coils be used in the production of medical equipment?

- Yes, steel coils can be used in the production of medical equipment. Steel is a versatile material known for its strength, durability, and ability to withstand various environmental conditions. It is commonly used in the manufacturing of medical equipment such as surgical instruments, orthopedic implants, hospital beds, and diagnostic machines. Steel coils are often utilized as a raw material in the production process. They can be processed and formed into various shapes, sizes, and components required for medical equipment. The coils can be cut, shaped, and welded to create intricate parts with precise specifications, ensuring the quality and performance of the final product. Moreover, steel coils can be surface-treated to enhance their corrosion resistance, making them suitable for use in medical environments where cleanliness and hygiene are crucial. Coatings such as electroplating or powder coating can be applied to provide an additional layer of protection against rust and other forms of degradation. Furthermore, steel is a cost-effective material, which makes it an attractive choice for medical equipment manufacturers. Its availability and affordability make it a preferred option for producing high-quality medical devices while keeping the production costs manageable. In summary, steel coils can indeed be used in the production of medical equipment. Their strength, durability, versatility, and cost-effectiveness make them an ideal choice for manufacturing various components and instruments used in the healthcare industry.

- Q: How are steel coils inspected for coil weight accuracy?

- Steel coils are inspected for coil weight accuracy using weighing scales or load cells. The coils are placed on the scales or load cells, and the weight is measured to ensure it matches the specified weight range.

- Q: What are the different types of packaging for steel coils?

- There are several different types of packaging options available for steel coils, depending on the specific requirements and preferences of the manufacturer or distributor. Some of the most common types of packaging for steel coils include: 1. Wooden Crates: Steel coils can be packed in wooden crates, which provide excellent protection against damage during transportation and handling. These crates are typically made of strong and durable wooden materials, such as plywood or solid wood, and are designed to securely hold the steel coils in place. 2. Steel Frames: Another common packaging option for steel coils is steel frames. These frames are constructed using sturdy steel materials and are designed to hold the coils securely in place to prevent any movement or shifting. Steel frames are often used for larger or heavier coils, as they offer enhanced stability and durability. 3. Cardboard Boxes: For smaller or lighter steel coils, cardboard boxes can be a suitable packaging option. These boxes are typically made of strong and durable cardboard materials, and they provide adequate protection against minor impacts and scratches. Cardboard boxes are also easy to handle and can be conveniently stacked or stored. 4. Plastic Wrapping: In addition to using crates, frames, or boxes, steel coils can also be wrapped in plastic materials for added protection. Plastic wrapping is typically used to secure the coils and protect them from moisture, dust, and other external elements during transportation and storage. This type of packaging is commonly used in conjunction with other packaging options. 5. Transportation Racks: For efficient handling and transportation, steel coils can be packaged in specially designed transportation racks. These racks are typically made of steel or other strong materials and are designed to securely hold the coils in place. Transportation racks allow for easy loading and unloading of the coils and provide enhanced safety during transit. Overall, the type of packaging chosen for steel coils depends on factors such as the size and weight of the coils, the transportation method used, and the level of protection required. Manufacturers and distributors often consider these factors in order to select the most appropriate packaging solution that ensures the safe and efficient handling of steel coils throughout the supply chain.

- Q: What is the role of steel coils in the manufacturing of pipes and tubes?

- Steel coils play a critical role in the manufacturing of pipes and tubes. They are the primary raw material used to produce these products. Steel coils are made by processing molten steel through a series of rolling mills, which shape the steel into flat, thin sheets. These sheets are then wound into coils for easy transportation and storage. In the manufacturing process of pipes and tubes, steel coils are unwound, and the flat sheets are passed through a series of machines and processes. The first step is usually to cut the steel sheets into the desired width and length. This is followed by forming the sheets into a cylindrical shape through a process called roll forming or continuous forming. The edges of the sheet are welded together to create a continuous pipe or tube. Steel coils provide several advantages in the manufacturing process. Firstly, they offer consistent and reliable quality. The production of coils ensures uniform thickness and strength throughout the entire length of the sheet, which translates to consistent properties in the final pipes and tubes. This is particularly important for applications that require high structural integrity and reliability. Secondly, steel coils allow for efficient production. The continuous supply of coils ensures a steady flow of raw material, reducing downtime and improving productivity. Coils also enable automated processes, such as roll forming, which can be highly efficient and cost-effective. Furthermore, steel coils offer flexibility in terms of size and dimensions. Coils can be produced in various widths and thicknesses, allowing manufacturers to customize the size and specifications of the pipes and tubes according to their specific requirements. This flexibility enables the production of pipes and tubes for a wide range of applications, from plumbing and construction to oil and gas pipelines. In conclusion, steel coils are the essential raw material in the manufacturing of pipes and tubes. They provide consistent quality, enable efficient production, and offer flexibility in size and dimensions. Without steel coils, the production of pipes and tubes would be significantly more challenging and less efficient.

- Q: So finally got around to watching man of steelnow i heard a few times that batman was in iti didn't se him.in the film is it something subtle I've just missed or is he not in it?when i googled it got loads of results for them being together in the new film but nothing about man of steel 2013

- Zod okorder /

- Q: How are steel coils used in the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery primarily for the fabrication of structural components and parts such as frames, chassis, axles, and brackets. The high strength and durability of steel make it an ideal material for these applications, ensuring the machinery can withstand the harsh conditions and heavy loads typically encountered in agricultural operations. Steel coils are processed and formed into the required shapes and sizes to create sturdy and reliable components that contribute to the overall performance and longevity of agricultural machinery.

- Q: What are the common tests performed on steel coils for quality assurance?

- Steel coils undergo various tests to ensure their quality and compliance with industry standards and customer needs. Dimensional inspection is a prevalent test that measures the length, width, and thickness of the coils to verify their specified dimensions. Any deviations in dimensions can indicate potential quality issues. A thorough visual inspection is also conducted to identify defects and surface imperfections like scratches, dents, or rust. This examination is crucial to identify any visual flaws that may affect the coils' performance or appearance. Furthermore, mechanical tests are carried out to assess the strength and durability of the steel coils. Tensile tests measure the maximum force the steel can withstand before breaking, determining its tensile strength, yield strength, and elongation properties. Another commonly performed mechanical test is the hardness test, which determines the steel's resistance to indentation, indicating its strength and toughness. These tests are typically conducted using methods like Rockwell, Brinell, or Vickers. Corrosion resistance is also evaluated as a vital aspect of steel coil quality. Tests such as salt spray or humidity tests simulate harsh environmental conditions to assess the steel's ability to resist corrosion. Lastly, chemical composition analysis is performed to ensure that the steel coils contain the necessary elements in the correct proportions. This analysis verifies that the steel meets the required chemical properties, which significantly impact its performance and suitability for specific applications. In summary, these common quality assurance tests guarantee that steel coils meet industry standards, customer requirements, and are suitable for their intended use.

- Q: They both sell the same thingIf prices are to high companies won't by the steelIf prices are to low then the steel company won't earn enoughWhy are some steel companies more successful than others

- Steel is a global commodity. There is some variety in product (flat rolled, tubing, etc), but basically the same product worldwide. Cost to the customer includes shipping of a very heavy product. Inputs are also heavy and costly to ship. Inputs: - Coal - Iron Ore. Some firms have the ability to recycle old steel, a competitive advantage. - Energy (very energy intensive industry) - Labor - Machinery. A new blast furnace is more efficient than 50 years old. So the most profitable steel firms have some of these characteristics: - Proximity to raw materials - Proximity to customers - Access to cheaper means of transportation; rail and sea - Newer machinery - Cheaper labor force - Reasonable cost for electricity and fuel for furnaces

- Q: Can steel coils be recoiled?

- Yes, steel coils can be recoiled. Recoiling involves rewinding a coil of steel to a smaller diameter, often to improve handling and transportation.

- Q: I have a steel string, Yamaha acoustic guitar that I am learning to play at home. But at school I use a rented nylon string guitar. I like the feel of the nylon strings better then the steel strings and i was wondering if i can just switch strings or if i should just get another guitar. Can anyone help?

- As okorder /..

Send your message to us

Pre-painted Galvanized Steel Coil/China PPGI for Roof Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords