Polyurethane Foam Sandwich Panels - Color Steel PU Laminboard

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | export standard seaworth package,or as per costomer request |

| Delivery Detail: | within 15 days after receive your prepayment |

Specifications

EPS sandwich panel

1.width:950-1000mm,

2.density:30-50kg/m3

3.thickness:50-200mm

4.MOQ:100squire meters

Cheat Sheet

Effective width | Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm |

Length | According to customer' s request |

materials | Polystyrene foam board(EPS), Color steel sheet,Rock wool |

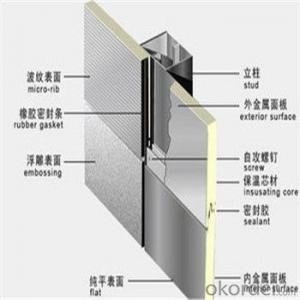

Structure | Upper and lower layer: Color steel sheet |

Middle: polystyrene foam board or polyurethane foam board or rock wool | |

Thickness | Color steel sheet: 0.3-0.6mm |

density | Rock wool 120-250kg/m3 EPS 12-35kg/m3 |

Conventional color | Ocean blue, tephrosious and other RAL color |

lifetime | 15~20 years |

Character | Light in weight, heat insulation, water resistant, green and environmental |

Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

Detailed Information

1.Product Description

Heat Insulation / Inflaming Retarding

Thickness: 50mm-200mm

Width: 950mm/1150mm

Steel Thickness: 0.35mm-0.80mm

Color: As request

This kind of Sandwich Panel has many features as follows:

2.Material:

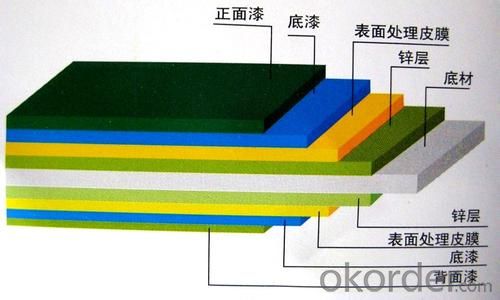

1. The thickness of up/lower steel panel: 0.35-1.2mm colour-coated panel/zinc plate, hot galvanized plate/stainless steel panel

2. Core material---The density of this(mineral)

Rock wool is: 120-250kg/m3

3. Side steel strip or not: 0.35-0.8mm galvanized plate

3.Specification:

1. The suitable interface width: 950mm, 1150mm

Thickness: 40mm-300mm

Length: No limit

2. Surface protection: PVC foil

Characteristics:

1. Advantage: Good fire-resistance, noise-absorbing

2. Fire resistance raring: None

4.Usage:

1)This kind of sandwich panel can be used in large industrial plants,warehouses

supermarkets, hospitals, stadiums, cold storage, activities room, buildings plus layer,

clean workshop and heat insulation fire place.2) sandwich plate appearance, bright color, good overall effect, it sets the bearing, thermal insulation, fireproof, waterproof in one, and no two decoration, is a widely used, especially in the construction site of the temporary facilities such as office, warehouse, walls, but also embodies the modern construction site civilization construction,

3) in the fast installation and put into use, the assembly and disassembly, material turnover multiplexing index, have obvious advantages, greatly reducing the construction site temporary facilities, will be indispensable new lightweight construction materials

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- Quantitative analysis of the problems exist in the security of the building, in a safe building. In order to solve this problem, you must first understand the specification. However, the specification is not enough, not only to understand the safety load calculation of scaffolding. Please forgive me, I am not here, in the past, it is too much trouble. Construction specifications are specified in this process, try to calculate. Technical specification for safety of fastener type steel pipe scaffold (JGJ130-2001)

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- Single row of scaffolding, that is, the entire frame by a row of pole composition; due to its small range (generally only used in decorative construction), poor stability, erection height is small, has gradually withdrawn from the construction market

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- The wall is relatively smooth, the external wall insulation per square meter with the mortar 4-foot often end of the shop to the whole shop 6 kg foot; wall is the wall, more mortar, a square need 7-9 kg

- Q: This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- Color steel sandwich panels have the effect of thermal insulation, these two types of panels can be used for houses and workshops, are able to waterproof

- Q: Sandwich panels and Malacca ecological board what is the difference

- Man can pipe the plastic tube can be directly within the tube to detect the actual deformation value

- Q: Are sandwich panels suitable for food kiosks?

- Sandwich panels are indeed appropriate for food kiosks. They have gained significant popularity in the construction industry due to their durability, insulation properties, and ease of installation. These panels consist of two external layers, typically constructed from metal, and a core material, such as polyurethane foam or rockwool, which offers outstanding thermal insulation. To meet food safety regulations, food kiosks necessitate a hygienic and clean atmosphere. Sandwich panels provide a smooth, non-porous surface that is simple to clean and maintain, making them an ideal choice for food kiosks. Furthermore, these panels offer thermal insulation, helping to maintain the appropriate temperature for storing and serving food, regardless of the climate. In addition, sandwich panels are lightweight, facilitating effortless transportation and assembly. This allows for quick setup and relocation if necessary. Moreover, they possess remarkable structural strength, ensuring stability and security for the kiosk. All in all, due to their durability, insulation properties, hygienic surfaces, and ease of installation, sandwich panels are a suitable option for food kiosks.

- Q: Color steel room life in general how many years

- Now the scaffolding is not how to use, one is relatively high cost, the second is a scaffolding scaffolding scaffolding safety, but compared with the disc scaffold, fastener steel scaffold relatively cheap, the current domestic use More is also a fastener scaffolding, just leaning on the tumbler betting set pull the disc, then foreign use more.

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- scaffolding must be set vertical and horizontal sweep longitudinal rod should be used at right angle fastener fixed at the bottom of the pipe at 200mm at the vertical pole should be fixed with fast nuts By the vertical pole pole

- Q: Color steel sandwich board on the price of how much?

- Solid wood particle board moisture-proof effect than the wood sandwich board moisture-proof effect is better than the solid wood particle board and wood sandwich board difference . solid wood particle board, is made of wood or other lignocellulosic material, after the application of adhesive Heat and pressure under the action of synthetic wood-based panel. Solid wood particle board as a new, high-grade environmentally friendly substrate. Solid wood particle plate inside the cross-scattered structure of the granular. So the nail force is good, you can nail round nails, screws. These machinability is significantly better than MDF. . solid wood particle density is higher, the board of wood fiber particles larger, more to retain the nature of natural wood, in the use of solid wood particles on the board content is generally less than 5%, better environmental protection. Solid wood grain plate warp deformation small, stable size, good, high strength, good stiffness, hanging heavy clothing is not easy to bend. At present in the European furniture market, the use of wood-based panel is also solid wood particle board. . wood sandwich panels inside and outside the two sides for the glass plate, sandwich layer waterproof plywood, the German vacuum technology from high pressure compound. Sandwich panel surface smooth, dirt can be easily removed, the entire panel colorful, with excellent light-blocking. . fiberglass plate surface has a layer of excellent performance gel coat, the atmosphere, water and the general concentration of acid, alkali, salt and other media has a good chemical stability; surface finish, excellent light retention, no discoloration, corrosion resistance , Anti-sun, anti-aging. The main application areas: dry cargo compartment, large span structure roof, wall, purification plant, high profile portfolio housing, container rooms and so on.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- General color steel foam sandwich panels. Price in the 45 - 60 yuan / M ? or so.

Send your message to us

Polyurethane Foam Sandwich Panels - Color Steel PU Laminboard

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords