PPGI JIS G3302 Best Prepainted Galvanized steel Coil

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 231 m.t.

- Supply Capability:

- 3123 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

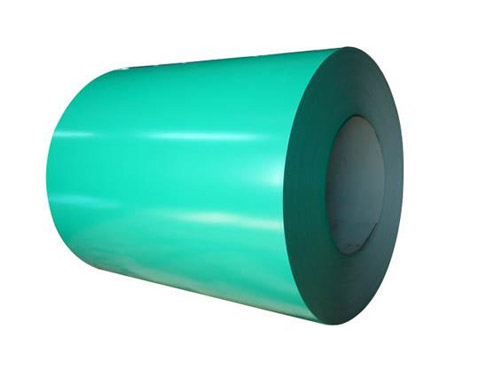

1.Structure of Prepainted Galvanized steel Coil :

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

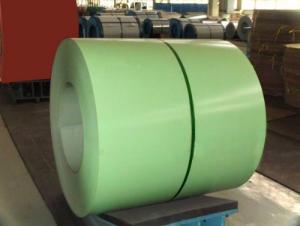

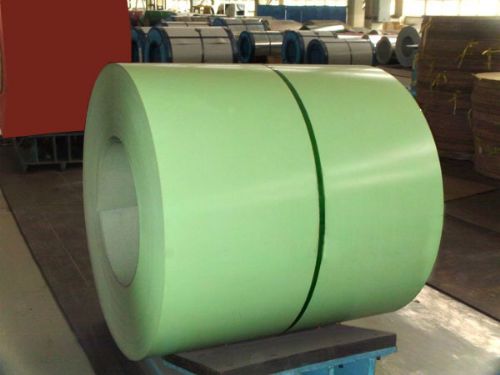

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized steel Coi

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: Can steel coils be welded together?

- Yes, steel coils can be welded together. Welding is a common technique used to join metals, including steel coils. It involves melting the edges of the coils and fusing them together using a filler material. This process creates a strong and durable bond between the coils, allowing them to be joined and used as a single unit. Welding steel coils together is commonly done in various industries, such as manufacturing, construction, and automotive, to create larger structures or components. However, it is important to ensure proper welding techniques and quality control measures are followed to ensure the integrity and strength of the weld joint.

- Q: Molten steel changes to solid steel at its __________ point. Could you please fill in the blank? Thank you so much, it is greatly appreciated. I have been looking for the answer to this question for a long time, but I never understand what the websites are trying to say because I don't have that big of a vocabulary and don't know what they mean. I've seen things saying steel boiling point, steel melting point, and steel freezing point. I don't know what any of those mean, and they might be the answer. Please help me. Thank you.

- just like a melting point of ice and the boiling point of water, there are different points where something is converted into another form. such as icewatersteam. it's always the same thing and it's a physical change, but just in a different form. molten steel changes to solid steel at it's freezing point. or solid point. i'm not sure how you would word that. but it would not be melting or boiling point. hope that helped.

- Q: What are the common manufacturing defects in steel coils?

- There are several common manufacturing defects that can occur in steel coils, including surface imperfections such as scratches, pits, or dents, dimensional inconsistencies such as uneven thickness or width, edge defects like burrs or cracks, and internal defects such as inclusions or voids. These defects can impact the quality and performance of the steel coils, and manufacturers strive to minimize these issues through quality control measures and inspections.

- Q: Will a stainless steel mesh screen scratch a titanium cup, or vice versa?I have a titanium french press and am thinking about replacing the included press with an all steel one. I am worried about little flakes of titanium or steel getting ground off into the coffee when the press slides in and out. The original press has a polyester cloth for a screen, so nothing scratches.

- Steel is usually harder than titanium, at least when both materials are hear-treated to give their best strengths. And a harder material can scratch a softer one. So I imagine that the answer is that it will scratch. However much of the rest of your question is unclear and it may be that the amount of friction between the two is so small that no wear will take place, so there could be no problem. The function of the polyester cloth may be vital in reducing this friction, so that unless you keep this part of the original design, the scratching will become worse no matter which combination of metals are used.

- Q: How do steel coils contribute to the automotive manufacturing sector?

- Steel coils are essential in the automotive manufacturing sector as they are used to produce various components such as body parts, frames, and suspension systems. The high strength and durability of steel coils make them ideal for ensuring the safety and structural integrity of vehicles. Additionally, steel coils are easily moldable, allowing manufacturers to create complex shapes and designs, contributing to the overall aesthetics and functionality of automobiles.

- Q: How are steel coils used in the manufacturing of electrical wiring?

- Steel coils are used in the manufacturing of electrical wiring to provide strength and support to the wiring. The steel coils are typically used as a core or reinforcement within the wiring to enhance its durability and prevent it from bending or breaking easily.

- Q: How do steel coil manufacturers ensure timely delivery?

- Timely delivery is ensured by steel coil manufacturers through a variety of strategies and measures. Their first priority is to maintain a well-coordinated system for production and supply chain management. This involves efficiently scheduling production processes, monitoring inventory levels, and closely coordinating with raw material suppliers. In addition, advanced forecasting techniques are often employed by steel coil manufacturers to predict product demand. By analyzing historical data, market trends, and customer behavior, they can anticipate future orders and plan production accordingly. This proactive approach minimizes the risk of delays and allows for better allocation of resources. Furthermore, close collaboration with transportation and logistics companies is essential to ensure smooth and timely delivery. Strategic partnerships are established and favorable agreements negotiated to facilitate efficient transportation of steel coils to customers. This includes optimizing routes, utilizing reliable carriers, and closely tracking shipments to promptly address any unforeseen issues. Moreover, buffer stocks may be maintained by manufacturers to mitigate the impact of unexpected disruptions, such as equipment failures or supplier delays. By having a safety stock of finished products, they can quickly respond to urgent orders and uphold their delivery commitments. Lastly, effective communication plays a crucial role in ensuring timely delivery. Steel coil manufacturers maintain open lines of communication with their customers, keeping them informed about production progress and potential delays. This transparency allows for proactive problem-solving and helps manage customer expectations. In conclusion, steel coil manufacturers employ efficient production and supply chain management systems, advanced forecasting techniques, collaboration with transportation and logistics companies, buffer stocks, and effective communication to ensure timely delivery. These strategies collectively enable them to meet delivery deadlines and provide reliable service to their customers.

- Q: could anybody tell me the the weight of a cubic metre of mild steel? and where to get this info from?

- i thnk 7.85 the density of ms is 7.85 kg/cm2 and formula is density=mass/volume u have volume=1m3 7.85*1=mass so 7.85 kg

- Q: I have been thinking of buying a knife that says it has damascus steel. The reason for the question is that many people told me that damascus steel does not exist anymore, and that damascus nowadays is fake. Is this true???

- damascus steel it says is made from ore containing either tungsten or vanadium, although most tools I've seen are made from chrome vanadium, it wouldn't be hard in this day and age to get the proper material. Although it DOES say in wikipedia that apparently the technique died out a long time ago due to shortage of the ore. Then it talks about reproduction attempts. So theoretically, yes, it could be the deal deal. But it does refer at the bottom about damascend steel which is made with a different technique, you could be buying one of those. NEXT TIME JUST LOOK UP THE ARTICLE YOURSELF AND READ IT

- Q: i currently have just steel guitar strings, not a fan they need replacing and i was wondering whats the difference between steel and bronze strings and or nickle strings?

- You may want to experiment with different alloys to find which sound best on your guitar...but if it's acoustic, you should be using bronze wound strings.

Send your message to us

PPGI JIS G3302 Best Prepainted Galvanized steel Coil

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 231 m.t.

- Supply Capability:

- 3123 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords