Best Prepainted Galvanized steel Coil JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Best Prepainted Galvanized steel Coil JIS:

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Best Prepainted Galvanized steel Coil JIS:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

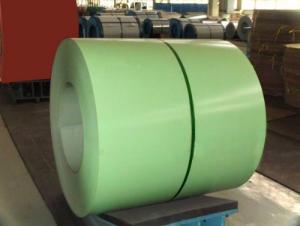

3.Best Prepainted Galvanized steel Coil JIS Images

4.Best Prepainted Galvanized steel Coil JIS Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Best Prepainted Galvanized steel Coil JIS

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components as they are typically used to form and shape various structural elements such as beams, columns, and trusses. These coils are unwound, flattened, and then processed through a series of machinery to be cut, shaped, and welded into the desired structural component. The steel coils provide a reliable and strong material base for the manufacturing process, ensuring the durability and stability of the final structural components.

- Q: What are the different types of steel coil treatments?

- There are several different types of steel coil treatments that are used to enhance the properties and performance of steel coils. These treatments include: 1. Annealing: Annealing is a heat treatment process that involves heating the steel coil to a specific temperature and then slowly cooling it. This treatment helps to relieve internal stresses, improve ductility, and increase the overall strength of the steel coil. 2. Pickling: Pickling is a chemical treatment that involves immersing the steel coil in a solution of acid or other chemicals to remove impurities, scale, and rust from the surface. This treatment helps to improve the surface finish and cleanliness of the steel coil. 3. Oil coating: Oil coating is a treatment that involves applying a thin layer of oil or other protective coating to the surface of the steel coil. This treatment helps to prevent corrosion, improve lubricity, and protect the steel coil during storage and transportation. 4. Galvanizing: Galvanizing is a process that involves coating the steel coil with a layer of zinc to protect it from corrosion. This treatment creates a barrier between the steel coil and the surrounding environment, ensuring long-term durability and resistance to rust. 5. Tempering: Tempering is a heat treatment process that involves heating the steel coil to a specific temperature and then rapidly cooling it. This treatment helps to improve the toughness and strength of the steel coil, making it more resistant to impact and deformation. These are just a few examples of the different types of steel coil treatments that are commonly used. Each treatment has its own specific purpose and benefits, and the choice of treatment will depend on the desired properties and application of the steel coil.

- Q: I heard that titanium isn't the most hypoallergenic metal because it is treated and the chemicals can cause an allergic reaction. I also heard that surgical steel is the best because it is what is used in surgery and in hip replacement implants etc. Is this correct?I've always heard that titanium is best, but now I'm curious because surgical steel is much cheaper than titanium which can be expensive.Thanks

- Implant grade titanium is much better than surgical steel. The nickel content in it (which is what alot of people are allergic to) is virtually non-existant. Though most people with a nickel allergy are fine with surgical steel too, its too small for most people to react to. But the odd few people do. Its the same with everything. Good surgical steel is probably better than cheap titanium. But implant grade ti will beat it hands down. And ti is alot stronger, and is also used in surgical impants and as replacement bits too. But a big lump of titanium hip is going to be expensive. If you're not allergic to steel, theres little reason for the extra cost, especially if it's likely to outlive you. Niobium has no nickel in at all. But that really is expensive, and I've never seen any threaded. Any particular reason why you ask? ----- Piercing-wise titanium will be better than steel. Unless they carry some not so great ti. You should be fine with steel though.

- Q: Myself, iam Working In a Steel Fabrication Company. I completed my Engineering in 2006 and immediately recruited in this company in Oman. My company is Steel Fabrication company .So as i am new to this field, i just need some basic knowledge regarding this Steel Fabrication.Waiting for ur early reply.

- make searches on internet; it's the best way to learn.

- Q: I have several stainless steel utensils and appliances, so when I put them through the dishwasher some of them are rusting, I think its because my current dishwashing soap is harsh, what is some great dishwashing soap that will clean my dishes and not be so hard on my stainless steel appliances and utensils?

- stainless steel does not work in a dish washer.Warm soapy water and dry straight away, they will last forever.

- Q: How are steel coils processed for edge trimming or conditioning?

- Steel coils are processed for edge trimming or conditioning through a series of steps. First, the steel coils are unwound and fed into a machine that trims the edges to remove any irregularities or imperfections. This process helps ensure that the edges of the steel coils are straight and smooth. After edge trimming, the coils may undergo further conditioning processes such as leveling, slitting, or recoiling, depending on the specific requirements of the end product. These processes help to refine the steel coils and prepare them for various applications in industries such as automotive, construction, or manufacturing.

- Q: How can steel coils be recycled?

- Steel coils can be recycled by first cleaning and removing any contaminants from the surface. Then, they are shredded into smaller pieces and melted down in a furnace. The molten steel is then formed into new coils or other steel products. This process helps conserve natural resources, reduces energy consumption, and minimizes waste.

- Q: Can steel coils be coated with impact-resistant materials?

- Yes, steel coils can be coated with impact-resistant materials.

- Q: How do steel coils contribute to strength and durability in manufacturing?

- Steel coils contribute to strength and durability in manufacturing in several ways. Firstly, steel is an inherently strong material due to its high tensile strength, which allows it to withstand heavy loads and resist deformation. When steel is coiled, it undergoes a process called hot rolling or cold rolling, which further enhances its strength and durability. During hot rolling, the steel is heated to high temperatures and then passed through a series of rollers, which compress and shape it into a coil. This process aligns the grain structure of the steel, making it more uniform and reducing internal stresses. The result is a stronger and more resilient material that can withstand the rigors of manufacturing processes such as bending, stamping, and forming without losing its structural integrity. Cold rolling, on the other hand, involves passing the steel through rollers at room temperature. This process not only increases the strength and hardness of the steel but also improves its surface finish. Cold-rolled steel coils are known for their smooth and uniform appearance, making them ideal for applications where aesthetics are important. Furthermore, steel coils can be coated with various protective layers to enhance their durability. These coatings, such as zinc or polymer-based coatings, act as barriers against corrosion, moisture, and other environmental factors that can weaken the steel. By preventing rust and degradation, these coatings extend the lifespan of steel coils and the products they are used in, making them more durable and cost-effective in the long run. In summary, steel coils contribute to strength and durability in manufacturing by providing a strong and resilient material that can withstand heavy loads and resist deformation. The hot rolling and cold rolling processes further enhance the strength and uniformity of the steel, while protective coatings help to prevent corrosion and extend the lifespan of the coils. Overall, steel coils are essential components in manufacturing that contribute to the strength and durability of a wide range of products.

- Q: How are steel coils used in the manufacturing of pressure vessels?

- Steel coils are used in the manufacturing of pressure vessels as they are processed into flat sheets and then formed into the desired shape. These coils provide strength and durability to the pressure vessel, ensuring it can withstand high pressures and temperatures.

Send your message to us

Best Prepainted Galvanized steel Coil JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords