Pre-Painted Galvanized/Aluzinc Steel Coil JIS G3312 with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. PPre-Painted Galvanized/Aluzinc Steel Coil JIS G3312 with Best Quality

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

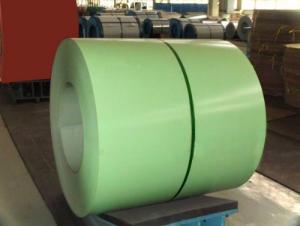

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the main factors that affect the price of steel coils?

- The main factors that affect the price of steel coils include the cost of raw materials such as iron ore, coal, and other alloys, supply and demand dynamics in the steel industry, production and transportation costs, fluctuations in currency exchange rates, and government policies and regulations. Other factors such as global economic conditions, trade tariffs, and market competition also play a significant role in determining the price of steel coils.

- Q: i need some ideas of what material could replace iron or steel to make fridges, stoves, dishwashers, tractors, aircrafts, cars and buses and anything else that is made of iron and steel. anything is greatly appreciated as at the moment i have no idea what to put down.

- Iron and steel has, in lots of cases, been replaced by Aluminium and its alloys. Titanium and composite (Carbon reinforced resin) materials are also used where weight saving and non bending strength is required. Many of these types of materials are expensive and as iron ore is readily available it will be some time before it is replaced on a wide basis. Many other materials are not good where higher temperatures are concerned however there is an increasing use of ceramics being used for say stove tops. Hope this helps.

- Q: The stainless steel drinking fountain had a little acid on it and rusted. I need to restore it. Is this possible?

- Stainless steel doesn't rust, whatever acid you got on it was some pretty bad stuff to make a reaction like that, you can try sanding down past the reaction point and polish it out but that's about it, that or it wasn't stainless to begin with. if its brushed chrome to simulate stainless it would have to be replated, not cheap. and probably not worth it

- Q: How are steel coils used in the manufacturing of body reinforcements?

- Steel coils are used in the manufacturing of body reinforcements by being processed and shaped into various structural components, such as beams and frames, which provide strength and support to the body of a vehicle. These reinforcements help enhance the vehicle's structural integrity, ensuring safety and protection for the occupants in the event of a collision or impact.

- Q: How do steel coils contribute to the energy storage industry?

- The energy storage industry benefits greatly from the use of steel coils in multiple ways. Initially, steel coils are instrumental in the fabrication of energy storage systems like batteries. Through their steel casing, batteries are provided with both structural support and protection for the battery cells, ensuring their safety and longevity. If not for steel coils, batteries would be more susceptible to damage and unable to function efficiently. Furthermore, the construction of flywheels, an alternative form of energy storage technology, heavily relies on steel coils. Flywheels store energy by spinning a rotor at high speeds and releasing the stored energy when necessary. Steel coils are employed to create the rotor, which necessitates strength, durability, and the ability to withstand substantial rotational forces. Additionally, the magnetic properties of steel contribute to the enhancement of energy transfer efficiency within the flywheel system. Moreover, compressed air energy storage (CAES) systems also utilize steel coils in their production. CAES systems store energy by compressing air and releasing it to generate electricity upon demand. Steel coils are crucial in constructing the air storage chamber, guaranteeing its integrity and preventing any leakage or damage. The robust nature of steel coils makes them ideal for enduring the high pressures associated with the compression process. To summarize, the energy storage industry greatly benefits from the utilization of steel coils. They provide essential structural support, durability, and protection to various energy storage technologies, whether it be batteries, flywheels, or CAES systems. By contributing to the efficient and secure storage of energy, steel coils facilitate the advancement and adoption of sustainable energy solutions.

- Q: Maybe it is obvious. But i have thought alot about it.I thought steel at a cool temperature was unbreakable. I am not one for science or physics or engineering (i am a political science major). But i don't understand why the planes that struck the world trade center on 9-11 didn't just dent the side and fall,How did the place break the steel? Was it the velocity? Is steel easily broken?I realized that i wasn't taught how the planes broke the steel, and that no one ever asked. I searched the web and i couldn't find the answer or even anyone who had asked the question before.(i don't care about conspiracy theories, i just want scientific facts)

- steel is not unbreakable. the world trade centers had a steel infrstructure, but were mostly glass and materials with many other flaws. steel is not the top of the rocwell scale(materials rated by thier hardness) when the planes impacted the outside of the buildings, you have to take into account that the planes skins and infrastructure where made of aluminum(too keep weight down) so once the outer skin of the planes was breached, you have to account for the heat created by burning fuel, friction, and the momentum of a vehicle that weighs tons hitting an immovible object. just keep in mind that if you propel a piece of straw at an proper speed, you can have it impale a full grown palm tree

- Q: What are the common industry standards for steel coils?

- Steel coils in the industry have varying standards depending on the region and specific use. However, there are widely accepted standards used in the steel industry. Among the most frequently used standards for steel coils is the American Society for Testing and Materials (ASTM) standard. ASTM has created various specifications for different types of steel coils, including hot-rolled, cold-rolled, and galvanized coils. These specifications outline the mechanical and chemical properties that the steel must meet, as well as dimensions, tolerances, and testing requirements. Apart from ASTM, international organizations like the International Organization for Standardization (ISO) and the European Committee for Standardization (EN) have also established standards for steel coils. ISO standards, such as ISO 3574 and ISO 5952, offer guidelines for general requirements, dimensional tolerances, and mechanical properties of steel coils. Similarly, EN standards like EN 10130 and EN 10131 specify the characteristics and tolerances for cold-rolled steel coils. Moreover, industry-specific organizations and associations may have their own standards for steel coils. For instance, the American Iron and Steel Institute (AISI) has developed specific standards for various steel products, including coils. These standards cover aspects including chemical composition, mechanical properties, and surface finish. It's worth noting that steel coil standards can also be determined by the intended use. Industries like automotive, construction, and manufacturing may have specific requirements that surpass general standards. In such cases, customers and manufacturers may refer to industry-specific standards or collaborate to define custom specifications. In summary, while there are several common industry standards for steel coils, it is crucial to consult the specific standards and requirements applicable to the region and application in question to ensure compliance and quality.

- Q: How are steel coils used in the production of automotive engine components?

- Steel coils are used in the production of automotive engine components by being processed and shaped into various parts, such as pistons, crankshafts, and connecting rods. The coils are first cut, stamped, and formed into the desired shapes, and then undergo heat treatment and other machining processes to enhance their strength and durability. These components are crucial for the proper functioning of an automotive engine, as they provide structural support and help convert the energy generated by the combustion process into mechanical motion.

- Q: We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- In okorder /... 11.7x8.3 inch paper 97.11 square inches 0.062651488 sq meters at 4.5gm is a non-standard 19 pound bond ledger paper, but that is OK, because at least it is in range. 38 gauge steel sheets are about the thinnest that hold their structure 0.00625 thick 1221 g/m? or, at 11.7x8.3 76.5grams So, with this data at hand we can better visualize the situation. Paper of 0.00625 thick in the size shown is 35# paper 131.68 g/m? 8.25grams Steel is higher in density than paper, so you cannot get the same size and air flow without it being lighter in weight than the steel and the air resistance would be lower for the heavier item, so steel of the same shape and thickness as paper falls faster. Suppose you want paper heavier than steel for the same area, then the thickness increases. Will a steel sheet 0.00625 thick and 11.7x8.3 inch size 76.5gm fall faster or slower than a 9 or 10 times thicker paper sheet? If it was able to hold flat in each type the thicker paper should get more backflow behind it aerodynamically and fall faster than an equal weight thinner steel sheet as my guess, but I don't have those numbers. The steel will always be heavier than the paper for the same exact shape and thickness by about 9x. My answer here is difficult, but the question has some flaws to think about.

- Q: Is a steel plate the same as a steel coil?

- Generally speaking, they can be used interchangeably, and the purchase price of the plate is slightly cheaper.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil JIS G3312 with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords