Al-Zinc Coated steel coil for Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

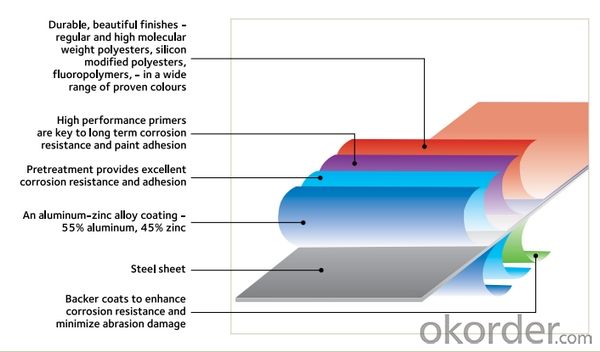

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How does the thickness of a steel coil affect its applications?

- The applications of a steel coil are significantly affected by its thickness. The thickness of the coil is what determines its strength, durability, and versatility, thus making it suitable for various uses in different industries. In industries where strength is of utmost importance, such as construction, thicker steel coils are preferred. Thicker coils provide higher structural integrity and load-bearing capacity, which are essential in projects involving buildings, bridges, and infrastructure. Moreover, thicker steel coils offer better resistance against bending, warping, and other forms of deformation, making them ideal for heavy-duty applications. The durability of a steel coil is also influenced by its thickness. Thicker coils exhibit greater resistance to wear, corrosion, and damage, making them suitable for harsh environments or applications that involve constant friction or exposure to elements. For instance, thicker steel coils are commonly utilized in the manufacturing of heavy machinery, automotive parts, and mining equipment, where durability is of paramount importance. Furthermore, the thickness of a steel coil determines its versatility and adaptability. Thinner coils can be easily shaped into different forms and sizes, making them suitable for applications that require intricate designs or tight tolerances. Industries such as automotive, aerospace, and consumer electronics often rely on thinner steel coils due to their lightweight and flexible nature. On the other hand, the weight and reduced flexibility of thicker steel coils may limit their range of applications. They are better suited for applications that prioritize strength and durability over versatility. These applications include structural components, large-scale machinery, and industrial equipment. To summarize, the thickness of a steel coil plays a pivotal role in determining its applications. Thicker coils offer increased strength, durability, and resistance, making them ideal for heavy-duty applications in the construction and manufacturing industries. Conversely, thinner coils provide versatility and adaptability, making them suitable for applications that require intricate designs or lightweight properties.

- Q: What are the environmental considerations when using steel coils?

- Some environmental considerations when using steel coils include the emissions and energy consumption associated with the production and transportation of the coils, as well as the potential for waste generation during processing and disposal. It is important to ensure that steel production practices adhere to sustainable and eco-friendly standards to minimize the environmental impact. Additionally, proper handling and recycling of steel coils at the end of their life cycle is crucial to reduce resource depletion and waste accumulation.

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to efficiently store and transport large quantities of steel in a compact and secure manner.

- Q: What are the main factors that affect the quality of steel coils?

- The main factors that affect the quality of steel coils include the composition and purity of the steel, the manufacturing process, temperature control during production, and the level of surface defects or imperfections. Additionally, the storage and handling conditions, as well as the expertise of the manufacturer, can also impact the quality of the steel coils.

- Q: What are the main factors that affect the paint adhesion on steel coils?

- The main factors that affect paint adhesion on steel coils include surface cleanliness, surface roughness, surface preparation methods, coating formulation, and application technique.

- Q: ok I got a dpms ar 15 and all i have put though it is good brass 223 ammo but is it ok to shoot the old crappy steel cased wolf ammo out of it will it hurt its function or will it hurt it cosmetically?

- The primary complaint about wolf steel cased stuff besides it being dirty is that is wears out the chamber and extractor faster than brass. That is not true. It would be true if the cases were actually steel instead of a mixture that has a hardness that is close to brass. Now to prove how pervasive this myth is I expect a minimum of 4 thumbs down for this statement alone. In any case the only issue is that is you do use steel cased ammo the chamber has to be better cleaned. The residue left behind from the coating on the steel casings will build up. If you keep firing the cheap steel cased stuff this tend to be less of an issue but when you use brass cased ammo without cleaning the chamber out or in the same session once it heats up the stuff will actually grip the brass tightly causing case head tears. And your only option is to wait for the gun to cool down yank it out by hand because at that point the casing is in essence glued into the chamber.

- Q: What does "steel roll number" mean?

- The coil numbers in the steel industry are generally applicable to rolled round steel bars. A coil of steel has a specified length and weight. Different rolls have different volumes

- Q: i want to know if i should buy a set of acrylic tapers or steel. they r close in cost so it's not a money factor i want to know which work better and if there is a downside to either. thanks!

- It relies upon on your physique and what you desire. in case you physique is allergic to a minimum of one in all them you may would desire to chosen for yet another one. If this is not any longer allergic to any, than you need to use in spite of you like the main, in simple terms attempt the two.

- Q: What are the common applications of hot-rolled steel coils?

- Hot-rolled steel coils possess distinctive characteristics and versatility, making them widely utilized in diverse industries. The following are some of the common uses of hot-rolled steel coils: 1. Automotive industry: Extensively employed in the automotive sector, hot-rolled steel coils are ideal for manufacturing components such as frames, doors, hoods, wheels, and chassis due to their strength and formability. This enables the production of durable and lightweight automotive parts. 2. Construction sector: Hot-rolled steel coils are widely employed in construction projects to manufacture structural components like beams, columns, and trusses. Their high strength and ductility make them suitable for withstanding heavy loads and providing structural stability. 3. Manufacturing industry: The manufacturing sector utilizes hot-rolled steel coils to produce a wide range of products including machinery parts, pipes, tubes, and equipment. Hot-rolled steel's excellent machinability and weldability allow for easy fabrication and customization according to specific manufacturing requirements. 4. Energy sector: The energy sector employs hot-rolled steel coils to manufacture pipelines, tanks, and other infrastructure required for oil and gas exploration, transmission, and storage. Hot-rolled steel's corrosion resistance and strength make it a preferred choice for such applications. 5. Appliances and furniture industry: Hot-rolled steel coils are used in the manufacturing of appliances such as refrigerators, ovens, and washing machines, as well as furniture components like frames and supports. The aesthetic appeal, durability, and cost-effectiveness of hot-rolled steel make it a popular choice in these industries. 6. Shipbuilding industry: The shipbuilding sector extensively relies on hot-rolled steel coils for constructing components like hulls, decks, and bulkheads. Hot-rolled steel's high tensile strength and corrosion resistance ensure the durability and longevity of ships in harsh marine environments. 7. Infrastructure and bridge construction: Hot-rolled steel coils are utilized in the construction of bridges, highways, and other infrastructure projects. The high strength and load-bearing capacity of hot-rolled steel make it suitable for supporting heavy traffic and withstanding dynamic loads. In conclusion, hot-rolled steel coils are utilized in various industries including automotive, construction, manufacturing, energy, appliances and furniture, shipbuilding, and infrastructure. The unique properties of hot-rolled steel, such as high strength, formability, and versatility, make it an indispensable material for a wide range of applications.

- Q: Is a steel plate the same as a steel coil?

- Generally speaking, they can be used interchangeably, and the purchase price of the plate is slightly cheaper.

Send your message to us

Al-Zinc Coated steel coil for Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords