PPGI Coils Color Coated Steel Coil RAL9002 White

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PPGI Coils Color Coated Steel Coil RAL9002 White

Details of PPGI Coils Color Coated Steel Coil RAL9002 White

Grade | DX51D, SGCC, CGCC |

Thickness | 0.15mm-1.5mm |

Width | 600mm-1500mm(914/1219/1250 are available) |

Standard | JIS G3312, ASTM,GB/T1275 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Length | As per requests |

Zinc Coating | 40g-275g/m2 |

Lacquer Coated | 20-25 microns/5-15 microns |

Coil ID | 508mm/610mm |

Coil Weight | normally 3-10mt or as your requirement |

Supply ability | 200,000Mt/year (MOQ:25Mt) |

Color | RAL No. |

Price terms | FOB,CFR,CIF |

Payment terms | L/C,T/T |

Deliver time | 30days after received deposit or L/C |

Packing | Standard exporting package |

steel strip Water proof paper, metal covers, | |

Application | Corrugated roofing,outside building, |

boating building,car producing | |

household appliance | |

Main market | Southeast Asia , the EU, Russia, Ukraine , Latin America and other countries and Regions |

Specification of PPGI Coils Color Coated Steel Coil RAL9002 White

Thickness | Width | Length of plate | Inner diameter of coil |

0.18-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass: | |||

Available Coated Mass(g/m^2) | Base plate | Available Coated Mass(g/m^2) | |

60,80, 100, 120, 160, 180 | Galvanized Steel | 60,80, 100, 120, 160, 180 | |

50, 70, 150 | Galvalume Steel | 50, 70, 150 |

Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20±5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface |

|

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coatin | Primer coating + Finish back coating | 2/2 | |

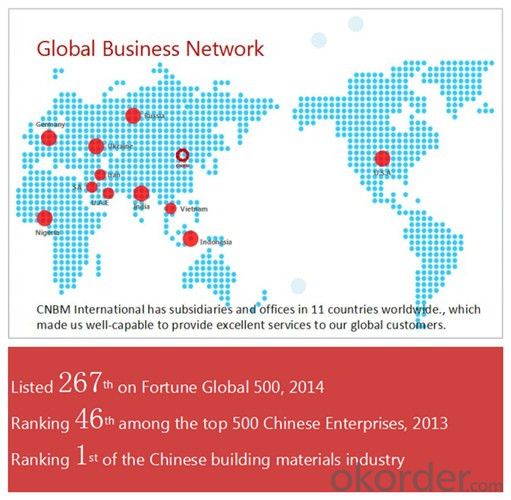

CNBM Introduction of PPGI Coils Color Coated Steel Coil RAL9002 White

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of PPGI Coils Color Coated Steel Coil RAL9002 White

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

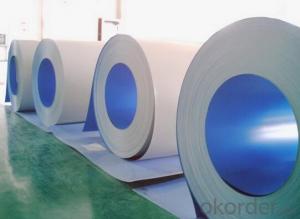

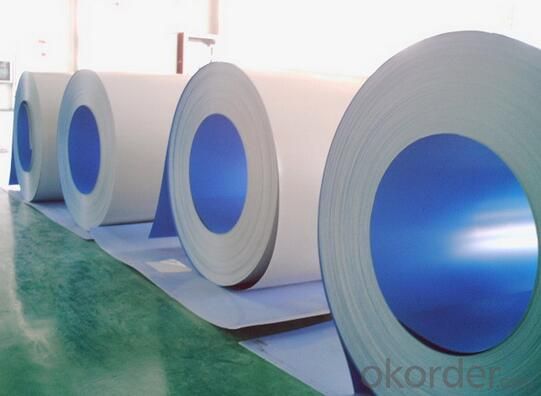

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel perform in terms of creep resistance?

- Special steel typically performs very well in terms of creep resistance. Due to its unique composition and heat treatment, it can withstand high temperatures and prolonged stress without deforming or failing. This makes it an excellent choice for applications that require long-term stability under extreme conditions, such as in power plants or aerospace industry.

- Q: How does special steel contribute to the renewable energy industry?

- Special steel plays a crucial role in the renewable energy industry by providing the necessary strength, durability, and resistance to extreme conditions for various applications. It is used in wind turbines, solar panels, and hydroelectric infrastructure, enabling the efficient and reliable generation of renewable energy. Special steel also helps enhance the performance, efficiency, and lifespan of these renewable energy systems, ultimately contributing to the sustainability and growth of the industry.

- Q: How does heat treatment affect the properties of special steel?

- Heat treatment can significantly impact the properties of special steel. The process involves heating and cooling the steel in a controlled manner, which alters its microstructure, resulting in changes to its hardness, strength, toughness, and ductility. By carefully selecting the temperature and duration of heat treatment, desired properties such as improved hardness, increased strength, and enhanced wear resistance can be achieved. Additionally, heat treatment can also relieve internal stresses, enhance machinability, and improve dimensional stability of special steel.

- Q: Can special steel be used in marine applications?

- Yes, special steel can be used in marine applications. Special steel, such as stainless steel or corrosion-resistant steel, is commonly used in marine environments due to its high resistance to corrosion, saltwater, and extreme weather conditions. It provides durability and longevity, making it suitable for various marine applications like shipbuilding, offshore structures, and marine equipment.

- Q: How does spring steel maintain its elasticity?

- Spring steel maintains its elasticity due to its unique composition and manufacturing process. It is made from a high carbon steel alloy that undergoes heat treatment and quenching, which gives it its exceptional strength and flexibility. This heat treatment process called tempering allows the steel to retain its shape and bounce back to its original form after being deformed or subjected to external forces. The carbon content in spring steel also contributes to its elasticity by providing increased hardness and resistance to deformation. Overall, the combination of high carbon content, heat treatment, and quenching make spring steel highly durable and able to maintain its elasticity over extended periods of use.

- Q: How does special steel contribute to the fatigue resistance of products?

- Special steel contributes to the fatigue resistance of products through its unique properties and manufacturing processes. Firstly, special steel is specifically designed and engineered to have enhanced strength and durability, making it highly resistant to fatigue. This is achieved by incorporating alloying elements such as chromium, nickel, molybdenum, and vanadium, which improve the material's ability to withstand cyclic loading and stress. In addition, special steel undergoes rigorous heat treatment processes, such as quenching and tempering, to further enhance its fatigue resistance. These processes help refine the microstructure of the steel, resulting in a more uniform and fine-grained material. This, in turn, improves the steel's resistance to crack initiation and propagation, which are key factors leading to fatigue failure. Moreover, special steel often undergoes specialized surface treatments, such as shot peening or nitriding, which introduce compressive residual stresses on the surface of the material. These compressive stresses act as a barrier against crack formation and growth, significantly enhancing the fatigue resistance of the product. Additionally, special steel can be manufactured with specific grain orientations, such as through the use of directional solidification techniques. This allows for the alignment of grains along the primary loading direction, improving the material's fatigue performance by reducing the likelihood of crack initiation at grain boundaries. Overall, the unique properties and manufacturing processes associated with special steel contribute to its exceptional fatigue resistance. Its enhanced strength, refined microstructure, specialized surface treatments, and tailored grain orientations all work together to prolong the lifespan and reliability of products, making special steel a preferred choice in various industries where fatigue failure is a concern.

- Q: How is special steel stored and transported?

- To maintain the quality and integrity of special steel, it is handled with utmost care during storage and transportation. During storage, the steel is kept in a controlled environment with the right temperature and humidity levels to prevent corrosion and damage. Covered warehouses and storage facilities specifically designed for steel are used to shield it from rain, snow, and sunlight. When it comes to transportation, different methods are employed depending on the quantity and distance. For short distances, smaller amounts of steel are transported using trucks equipped with flatbeds or enclosed trailers. These trucks are designed to securely hold and protect the steel, ensuring it does not shift or get damaged during transit. However, for longer distances or larger quantities, rail or sea transportation is preferred. Rail transportation offers a smooth and stable journey, minimizing the risk of damage caused by vibrations or sudden movements. Specially designed railcars are used to securely store and protect the steel during transit. Sea transportation involves loading the steel onto shipping containers or specialized vessels. Containers are sealed and secured to prevent any movement or damage during the journey. Specialized vessels, such as roll-on/roll-off ships or heavy-lift vessels, are used for oversized or extremely heavy steel components. In all cases, special steel is carefully packaged and secured using appropriate materials like wooden crates, steel strapping, or plastic wrapping to prevent scratches or dents. The transportation process is closely monitored, and necessary precautions are taken to ensure the steel reaches its destination in optimal condition. Overall, the storage and transportation of special steel require thorough planning, proper handling, and the use of specialized equipment to safeguard its quality and protect it from potential damage or degradation.

- Q: What are the factors that affect the machinability of special steel?

- There are several factors that can affect the machinability of special steel. First, the composition of the steel, including the type and amount of alloying elements present, can significantly impact its machinability. Additionally, the hardness and microstructure of the steel, which are influenced by factors such as heat treatment and processing, can also affect how easily it can be machined. Other factors that can play a role include cutting tool selection, cutting speed, feed rate, and coolant or lubricant used during machining.

- Q: Can special steel be used in the agricultural industry?

- Yes, special steel can be used in the agricultural industry. It offers various benefits such as high strength, durability, corrosion resistance, and the ability to withstand harsh environmental conditions. It can be used for manufacturing agricultural machinery and equipment like tractors, plows, harvesters, and irrigation systems, improving efficiency and productivity in the agricultural sector.

- Q: What are the common techniques for testing the quality of special steel?

- Some common techniques for testing the quality of special steel include chemical analysis, mechanical testing, non-destructive testing, and metallography. Chemical analysis involves examining the composition of the steel to ensure it meets the required specifications. Mechanical testing involves subjecting the steel to various forces and measuring its strength, hardness, and other mechanical properties. Non-destructive testing methods such as ultrasound, radiography, and magnetic particle inspection are used to detect any defects or flaws in the steel without causing damage. Metallography involves examining the microstructure of the steel under a microscope to assess its grain size, inclusion content, and overall quality. These techniques help ensure that special steel meets the necessary standards and requirements.

Send your message to us

PPGI Coils Color Coated Steel Coil RAL9002 White

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords