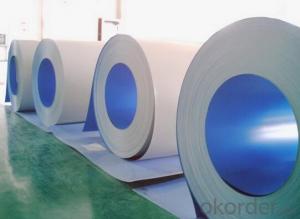

PPGI color coated steel coil with 0.23*914mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1). Zinc coat:60g-275g

2). Color: Any RAL colors to your demands.

3). Paint coating :Normal polyester coating.

1) Commodity | Hot dip galvanized steel coil and sheet |

2) Techinical Standard | AISI,ASTM,GB,JIS |

3) Grade | SS grade 33-80,SGCC, SGCH, SGCD1- SGCD3, SGC340-SGC570, SGCC, DX51D |

4) Thickness | 0.2-3.0mm |

5) Place of origin | China (mainland) |

6) Model Number | SGCC,SGCH,SGCD1-SGCD3,DX51D |

7) Type | Steel Coil,Steel Plates |

8) Technique | Cold Rolled |

9) Surface Treatment | Galvanized |

10) Application | wide construction range,household appliance |

11) Special Use | High-strength Steel Plate |

12) Width | 600-1250mm |

13) Length | as per customer's requirement |

14) Coil ID | 508/610mm |

15) Coil weight | 3-8 MT per coil |

16) Zinc Coating | Z40-275g/m2 |

17) Surface structure | normal spangle, large spangle, small(min) spangle,zero spangle |

18) Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

19) Steel grade | SS grade 33-80,SGCC, SGCH, SGCD1- SGCD3, SGC340-SGC570, SGCC, DX51D |

20) Certificate | ISO9001TUV |

21) Payment terms | T/T or L/C |

22) Delivery time | 7-25 days after recepit of 30% TT |

23) Packaging Detail | Standard seaworthy export package |

24) Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certificatation test |

- Q: describe the benifits and disadvantages of the using steel as a material for fasteners

- There are different grades of steels which can suit different application considering corrosion,surrounding atmosphere,pressure,temperature and many more. Let us take the stainless steel fasteners: 1.Resists Rust: The primary advantage to using stainless steel bolts is that they resist rusting. This makes them ideal for outdoor or marine uses, since moisture will not cause them to corrode. Rust basically eats steel and makes it weaker. A rusty, weak bolt can be a serious safety risk, because it can break under a load. 2.Clean: Stainless steel bolts are very easy to clean due to having a higher content of chromium, which creates a lustrous, mirror-like surface that is very smooth. This makes stainless steel an ideal option if aesthetics are an issue. 3.Temperature: Stainless steel has a high melting point, which makes it a good option in machines that are put through immense amounts of heat. The bolts will not fuse together, and can be unfastened when the machines need repairs. Also, in very cold conditions, steel can become brittle. By mixing nickel into the stainless steel, the metal resists becoming brittle at low temperatures. See the source link for details.

- Q: What are the different types of steel coil grades and specifications?

- There are several different types of steel coil grades and specifications available in the market. These grades and specifications are designed to meet various industry requirements and applications. Some of the commonly used steel coil grades and specifications are: 1. Hot Rolled Steel Coils: These coils are produced by heating the steel above its recrystallization temperature and then rolling it at a high temperature. Hot rolled steel coils are commonly used in applications where dimensional accuracy and surface finish are not critical. 2. Cold Rolled Steel Coils: Cold rolled steel coils are produced by further processing hot rolled coils through cold reduction mills. This process results in improved surface finish, tighter tolerances, and higher strength compared to hot rolled coils. Cold rolled steel coils are widely used in automotive, construction, and electrical industries. 3. Galvanized Steel Coils: Galvanized steel coils are coated with a layer of zinc to protect them from corrosion. This process, known as galvanization, enhances the durability and longevity of the steel coils. Galvanized steel coils are commonly used in applications such as roofing, fencing, and automotive body parts. 4. Stainless Steel Coils: Stainless steel coils are made from a combination of iron, chromium, and other elements that provide excellent corrosion resistance and high strength. These coils are widely used in industries such as food processing, chemical, and medical, where hygiene and corrosion resistance are critical. 5. High-strength Low-alloy (HSLA) Steel Coils: HSLA steel coils are designed to have higher strength and improved formability compared to conventional carbon steels. These coils are commonly used in structural and transportation applications, where weight reduction and high strength are required. 6. Electrical Steel Coils: Electrical steel coils, also known as silicon steel or transformer steel, are specifically designed for use in electrical equipment such as transformers, motors, and generators. These coils have low core losses and high magnetic permeability, making them ideal for efficient energy transfer. 7. Tool Steel Coils: Tool steel coils are specially formulated to have high hardness, wear resistance, and toughness. These coils are commonly used in the manufacturing of cutting tools, dies, and molds. These are just a few examples of the various types of steel coil grades and specifications available in the market. The selection of the appropriate grade and specification depends on the specific application requirements, such as strength, corrosion resistance, formability, and surface finish.

- Q: Can steel coils be coated with zinc-aluminum alloy?

- Yes, steel coils can be coated with a zinc-aluminum alloy through a process called hot-dip galvanizing. This coating provides enhanced corrosion resistance and improved durability to the steel coils.

- Q: why were guns, germs and steel absent within America?

- i dont really understand this question but if it means to how it was before then it was absent because the native americans were not into technology so they obviously had no guns created that was something that they had traded to get from europe as for the germs i ddo not know about thta really except for if it means that common disease and one of the diseases most used in history books is malaysa from mosquitos but when they had traded with europe they got all sorts of diseases now for steel the only reason i remember them traveling for is for gold and i dont remember them ever looking for it until 13 colonies were established as you can see im not exactly sure about germs and steels but i know that the guns part is correct

- Q: Can steel coils be coated with vibration-damping materials?

- Yes, steel coils can be coated with vibration-damping materials. The application of vibration-damping coatings can help reduce the transmission of vibrations and noise, enhancing the performance and durability of steel coils in various applications.

- Q: How are steel coils used in the production of transportation equipment?

- Steel coils are used in the production of transportation equipment, such as automobiles, ships, and trains, to create various structural components. These coils are typically shaped and formed into parts like chassis, frames, bodies, and panels, providing strength, durability, and stability to the vehicles. Additionally, steel coils can be used in the manufacturing of wheels, axles, and suspension systems, ensuring reliable performance and safety in transportation equipment.

- Q: How are steel coils inspected for coil weight accuracy after processing?

- Steel coils are typically inspected for coil weight accuracy after processing by using weighing scales or load cells that are capable of accurately measuring the weight of the coil. The coil is placed on the scale or load cell, and the weight is compared to the target weight specified for that particular coil.

- Q: Which movie is better and why?I say Man of Steel!

- Captain America

- Q: I wasn't expecting much because i knew it was cheap (Trying to avoid high prices) But anyway i cut a few bottles and cans and i noticed the very edge of the blade was starting to bend. I ignored it and tried it on a 3 inch limb, and the whole blade bent sideways where the limb hit it.I heard cold steel was supposed to be top quality and I wanted to know how durable their swords are and if they're worth it. Thanks!

- Yes. Cold Steel is a great company with a quality product, and I've always been happy with their work. Their katanas, while not made in the traditional method, are heavy duty carbon steel and should handle abuse well. I'd recommend them based on my experience with other Cold Steel products.

- Q: I've played guitar for years, now I want a steel guitar. As a beginner, to learn and experiment with, which one would be better for me?

- Pedal steel is very difficult. You need to co-ordinate both hands, both feet and both knees to play it effectively. Lap steel is a lot easier. I suppose it depends how much of a challenge you want. A good lap steel guitar is usually cheaper than a good pedal steel too, so that's another consideration to take into account.

Send your message to us

PPGI color coated steel coil with 0.23*914mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords