PPGI,Pre-Painted Steel Coil with Prime Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

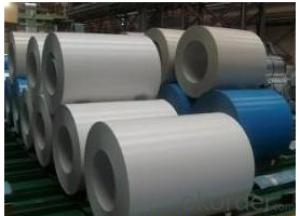

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of shock absorbers?

- Steel coils are commonly used in the manufacturing of shock absorbers as they provide the necessary strength and flexibility to absorb and dampen shocks and vibrations. These coils are typically placed inside the shock absorber to support the weight of the vehicle and absorb the impact caused by uneven road surfaces. The coiled steel springs compress and expand to absorb the energy from the shocks, ensuring a smoother and more comfortable ride for the vehicle occupants.

- Q: I want to buy a chain that will last a long time and that i can wear ALL the time.What are the disadvantages to stainless steel jewelry?Does it look as good as silver?Is there much diference in apperance?

- All of I know are stainless steel advantages. it won't stain, corrode, or rust easily. And it keeps its good-looking shine even for many years.

- Q: My boyfriend is a loyal follower of this guy called Dr. Steel.

- Dr. Steel is an extremely complex phenomenon, a bit of a metaphorical nesting doll. On the surface, Dr. Steel can appear to some as simply a method actor musician with an over-the-top gimmick. Just underneath that facade lies an enigma; he makes some people wonder if he's really serious, just trying to entertain, or completely barking mad. But underneath the second facade, Dr. Steel is really acclaimed comic-book writer and chaos magickian, Grant Morrison. Make no mistake, he really thinks he is Dr. Steel. He has taken method acting and ceremonial magick to the highest levels, and fully intends to take over (or make over) the world. What's more, in the three short years since handing over his comic-book authorship to a ghost writer, he has amassed tens of thousands of followers worldwide. I've done several polls among Dr. Steel fans, and the results show that for every one person who has officially signed up, there are ten more loyal followers who have not.

- Q: This is my first time buying new strings for my violin and I’ve narrowed it down to two choice based on reviews and cost. The only difference I can see between the strings is that one has a solid steel core and the other has a synthetic core. What are the pros and cons of each type of core?

- It depends on the tone you want. Synthetics are a more artificial, but rich tone. Solid steel strings will have a beautiful and bright tone, but may be a tad bit more difficult to play.

- Q: How are steel coils inspected for surface cleanliness?

- Steel coils are inspected for surface cleanliness through various methods such as visual inspection, magnetic particle testing, and ultrasonic testing. These techniques help identify and remove any contaminants or defects that may be present on the surface of the steel coils.

- Q: How are steel coils processed for different finishes?

- Steel coils are processed for different finishes through various techniques such as hot rolling, cold rolling, pickling, and coating. Hot rolling involves heating the steel coils and passing them through rollers to achieve desired thickness and shape. Cold rolling further enhances the surface finish by reducing thickness and increasing strength. Pickling involves removing impurities and scale from the surface of the steel coils using acid solutions. Finally, coating techniques like galvanization or painting are used to provide protective and decorative finishes to the steel coils.

- Q: What is the maximum load capacity for steel coil storage racks?

- The maximum load capacity for steel coil storage racks can vary depending on the specific design and specifications of the rack. However, typically, steel coil storage racks can support loads ranging from a few thousand pounds to tens of thousands of pounds per level. It is important to refer to the manufacturer's guidelines and consult with structural engineers to determine the exact load capacity for a particular rack.

- Q: What's the difference between hot rolled coil and hot-rolled carbon thin steel coil?

- Hot rolled coil is used for continuous casting slab or as raw material, after reheating furnace heating, descaling into the roughing mill of high pressure water, roughing material by cutting head, tail, and then enter the finishing mill, the implementation of the computer controlled rolling, after finishing through the laminar cooling (computer controlled cooling rate and coiling) reel, a straight hair volume. Hair straightenerrollhead, tail tongue shapeand thefishtail shape, thickness, width of poor accuracy, edgehaswavy, folding, tower and other defects. The volume is heavy. (general management industry likes to use. )

- Q: What are the standard dimensions and weights of steel coils?

- The specific type and grade of steel being used, as well as the manufacturing process and intended application, can cause variations in the standard dimensions and weights of steel coils. However, there are some common industry standards that can give a rough estimate of the dimensions and weights. In terms of dimensions, steel coils usually have a standard width that can range from 600mm to over 2000mm. The most commonly used widths are 1000mm, 1250mm, and 1500mm. The inner diameter of the coil, which is also known as the core or mandrel, is typically around 508mm (20 inches) or 610mm (24 inches). On the other hand, the outer diameter of the coil, which is known as the outside diameter or OD, can vary greatly depending on the thickness and width of the coil. However, it usually falls within the range of 1200mm to 2000mm. When it comes to weights, steel coils are measured by their gross weight, which includes the weight of the coil itself and the steel material it contains. The weight of a steel coil can vary from a few hundred kilograms to several tonnes, depending on the thickness and width. For example, a coil with a thickness of 0.5mm and a width of 1000mm may weigh approximately 5-6 tonnes, while a coil with a thickness of 3mm and a width of 1500mm can weigh around 20-25 tonnes. It's important to keep in mind that these dimensions and weights are general guidelines and may differ based on the specific requirements and standards of different industries and manufacturers. Therefore, it is advisable to refer to the relevant specifications or contact the manufacturer for accurate and up-to-date information regarding the dimensions and weights of steel coils.

- Q: How does stainless steel soap work? I have read the detailed explanation on Wikipedia, but their desciption seems skeptical on the actual chemical process that may take place from using such an item. Is there an actual scientific explanation to how stainless steel soap is able to clean your hands, when it is only a piece of metal?

- Metal Soap Bar

Send your message to us

PPGI,Pre-Painted Steel Coil with Prime Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords