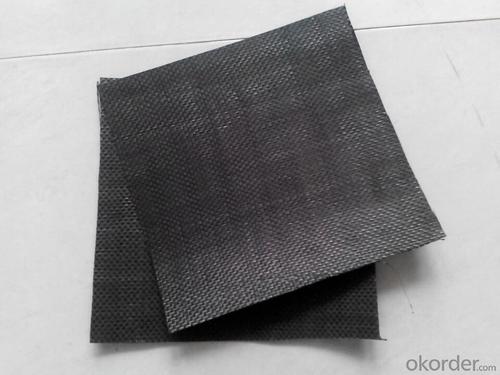

Mallas Geotextil PP Woven Ground Cover Weed Barrier Plastic Fabric Mat

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Product Name | --100% PP spundond nonwoven

|

What is non woven | Broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. They are flat, porous sheets that are made directly from separate fibers or from molten plastic or plastic |

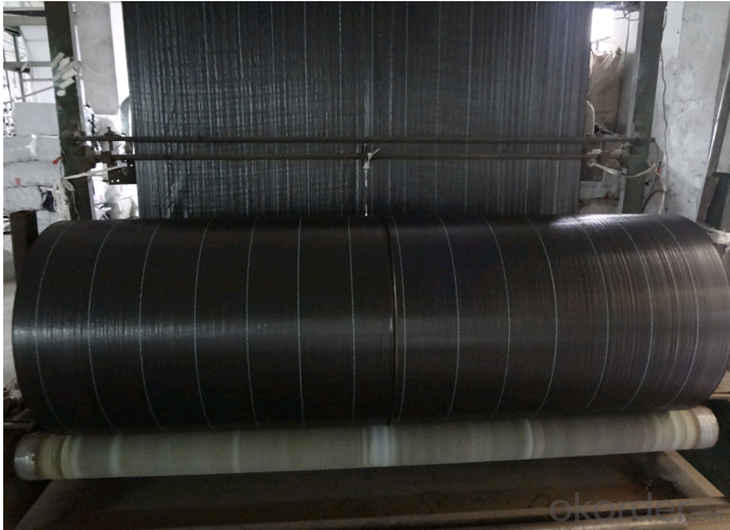

Line of Production | Intake materials-high temperature molten-spunlaid-high temperature hot rolled-Cutting & convoluting |

Composition | 100% polypropylene or pp with recycled pp |

Specification | Technique: spunbonded Weight range: 9gsm-260gsm Width:160cm,320cm (can be split) Embossing: dot Color: Varous color as customer request |

Characteristic | 1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well. 2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable. 3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash. 4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin. 5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and inse agricultural nonwoven fleece cts; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin. |

Application | --(10-40gsm) for medical/hygiene such as cap, mask, gown, face masks, foot cover --(15-70gsm) agricultural covers, wall cover, --(50-100gsm)shopping bags, suits pockets, gift bags, sofa upholstery --(50-120gsm) sofa upholstery, home furnishing, handbag lining, shoe leather lining |

Packing | --Rolled with paper tube inside and PE film outside |

Ground cover (weed mat) is used for: agricultural cultivation ,subgrade, road (roads, railways, airports) and ground stability.

Benefits

1. Excellent Weed Control

2. Exceptional UV resistance

3. Moisture, fertilizers, air reach plants to allow for healthy soil

4. Good water and air permeability

5. Exceptional toughness and strength

6. Durable, tear-resistant; Won't rot or mildew

7. Lightweight, easy to install, follows natural ground contours

8. Ideal for use in landscaped beds, under decks and walkways.

Packaging & Delivery

| Packaging Details: | Packed In Roll Or In Bales Or Cartons Or According To Customers Requirement |

| Delivery Detail: | 20 Days After Order Confirmed |

FAQ

1, Samples Policy

Samples are free, but the freight is on customers' charge

Samples will usually be sent out in one day.

2, Prices

As for the prices, we need you to provide us weight, color, width and usage so that

we can quote you best.

3, How to place an order?

Inquiry

Reply

Sample

Contract

Receiving deposit& production

Testing& Packing

Delivery

Receiving

- Q: Can geotextiles be used in erosion control on riverbanks?

- Yes, geotextiles can be used in erosion control on riverbanks. Geotextiles are permeable fabrics that can be placed on the surface of the riverbank to stabilize the soil and prevent erosion. They help in retaining soil particles while allowing water to pass through, thereby reducing the impact of flowing water on the riverbank and preventing further erosion.

- Q: Construction Method of Sand and Gravel Cushion on Slope Soil Geotextile

- Online to find some relevant construction methods, Google library on a lot. After downloading, modify, targeted to add that is the slope of geotextile sand and gravel cushion construction method.

- Q: Polypropylene geotextile and polyester geotextile with the naked eye how to distinguish

- Polypropylene compared to white, polypropylene fiber than polyester fiber density point, anti-aging anti-aging of polypropylene, polyester aging,

- Q: How do geotextiles reduce construction time and cost?

- Geotextiles reduce construction time and cost by providing a cost-effective solution for soil stabilization, erosion control, and drainage. They act as a barrier against soil erosion and allow for efficient water drainage, reducing the need for expensive excavation and backfilling. Moreover, geotextiles can be easily installed, saving time and labor costs. Additionally, they enhance the overall durability and lifespan of the construction by minimizing soil settlement and preventing the intrusion of fine particles.

- Q: Are geotextiles commonly used in agriculture?

- Yes, geotextiles are commonly used in agriculture. Geotextiles have multiple applications in the agricultural industry, including soil stabilization, erosion control, weed suppression, and drainage management. They help improve soil quality, reduce erosion, and enhance crop growth, making them a valuable tool for many farmers and agricultural practices.

- Q: Geotextile fng-pet-250-400

- Fng-filament is a polyester filament spunbonded acupuncture non-woven geotextile Cloth 250g / ㎡-400g / ㎡.

- Q: How do geotextiles help with soil stabilization in foundation construction?

- Geotextiles help with soil stabilization in foundation construction by providing reinforcement and separation functions. They act as a barrier between different soil layers, preventing their intermixing and maintaining their structural integrity. Additionally, geotextiles improve the load-bearing capacity of the soil by distributing the applied loads more evenly, reducing settlement and increasing stability.

- Q: Reservoir dam waterproof geotextile cloth two bags of a large package should be how much money

- Do not understand, to answer what is the problem with ah, Google then you deleted, Google know the system do not know how ah

- Q: What is the role of geotextiles in geotechnical engineering?

- Geotextiles play a crucial role in geotechnical engineering as they are used to enhance soil stability, reinforce slopes, and improve drainage systems. These permeable fabrics help prevent soil erosion, control sediment movement, and distribute loads efficiently. Additionally, geotextiles can be employed in various construction projects, such as roadways, embankments, and retaining walls, to provide strength and durability to the soil structure.

- Q: What are the key considerations for geotextile installation in seismic retrofitting projects?

- Some key considerations for geotextile installation in seismic retrofitting projects include selecting the appropriate type and strength of geotextile material, ensuring proper placement and anchoring of the geotextile, evaluating the stability and drainage requirements of the site, and considering the compatibility of the geotextile with other materials and construction methods used in the retrofitting project. Additionally, careful attention should be given to the design and installation of the geotextile to ensure it effectively enhances the overall stability and performance of the structure during seismic events.

Send your message to us

Mallas Geotextil PP Woven Ground Cover Weed Barrier Plastic Fabric Mat

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords