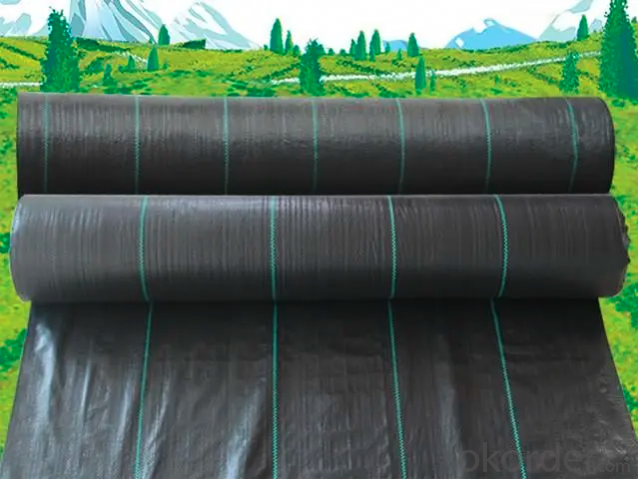

PP Woven Fabric/ Ground cover/ Weed Barrier

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Material: | 100% Polypropylene |

Width: | Max width is 260cm,can be slitting as customer's requirement |

Weight: | 10gsm-270gsm |

Type: | Hard, Soft, and Crispy etc.; |

Color: | Super White, White, Gray, Red, Green, Black, etc.; |

Non-woven Technology: | Spun-Bond |

Features: | Anti-bacterial,Anti-static,Anti-UV,Fireproof,Wtaerproof,Hydropilic,Laminated(pp+pe),Printed,Preforation,etc. |

Samples | Stock samples will be free,normaly have white one |

Port | Shanghai or Ningbo |

Payment | 30% deposit in advance,against the copy of B/L,pay the balance |

Delievery Time | About 15days after received u deposit |

Nonwoven fabric Usage:

(10-40gsm) for medical/hygiene as disposable medical products and decrotions on ceremony

(15-30gsm) diapers,personal healthcare products

(60-100gsm) shopping bags,tablecloth,compound packing material,filter material

(50-120gsm) household products,furniture,spring mattress,bedding and suitcase interlinging

(50-100gsm1-5%UV) agriculture covers and weed-control fabric

Features

1. Weed suppressant and drainage control landscaping fabric

2. Easy to use, Environmentally friendly

3. Allows water, air and nutrients through, suppressing weeds without the use of chemicals

4. Reduces the level of watering required due to the slower rate of water evaporation

Introduction

Geotextiles are composed from synthetic polypropylene/polyester fibres through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration.

Type: 1. Wovens & knitted: use various fibre types (e.g. monofilament, multi-filament, split extruded film) in different combinations.

2. Non-wovens: staple or continuous fibres that are heat treated or needlepunched to “fix” fibres relative to each other.

Specification

1) Weight / Mass: 75g/m2-400g/m2 .

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP

5) Color: Black , white , grey, others

6) Certificate: CE/ISO9001, ISO14001 .

7) Manufacturing method: nonwoven / woven.

8) The biggest geotextile manufacturer/factory in China for many years . The equipment is introduced from Germany.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Waiting to cooperate with you!

- Q: Water board and water pipes and quick overburden trees

- Set aside the road to pull the car, little by little to fill the soil, I am specializing in the production of geotextile, drainage board, wish smooth

- Q: We have built a swingset with a built in sandbox. I am looking for geotextile fabric to put under the sandbox to keep weeds & roots out. Any ideas where I can get this from? Local home improvement stores do not stock geotextile fabric. I bought some from a pool supply store for my pool bottom, but they don't sell custom sizes.

- I'm really surprised. All of the Lowe's, Home Depots, etc. that I know of stock landscape barrier fabric, as do all the garden supply shops. If you truly can't find any, carpet works well, as will corrugated cardboard for a season. If the kids use the sandbox a lot, they'll usually keep the weeds down, too.

- Q: What type of geotextile is used for soccer field

- Generally with permeable geotextile, 200g300g can be

- Q: What are the key considerations for geotextile installation in high-altitude regions?

- Some key considerations for geotextile installation in high-altitude regions include extreme weather conditions, such as low temperatures and high winds, which can impact the performance and durability of the geotextile. The choice of materials should be carefully evaluated to ensure they can withstand these harsh conditions. Additionally, the installation process should account for the potential difficulties in accessing the high-altitude location and the need for specialized equipment and skilled labor. The design and placement of the geotextile should also take into account the unique geological and environmental characteristics of the area, such as steep slopes, rocky terrain, and increased risk of erosion. Regular monitoring and maintenance of the geotextile should be conducted to ensure its long-term effectiveness in high-altitude regions.

- Q: How do geotextiles improve soil stability?

- Geotextiles improve soil stability by providing a barrier against erosion, reducing water flow velocity, promoting filtration, and enhancing soil confinement, thereby preventing soil movement and erosion.

- Q: How many grams of geotextiles on the top of the garage

- We would like to consult a professional company.

- Q: Are geotextiles commonly used in canal lining applications?

- Yes, geotextiles are commonly used in canal lining applications. They serve as a barrier to prevent soil erosion and provide stability to the canal lining. Geotextiles also help in filtering out fines and prevent the clogging of drainage systems in canals.

- Q: Geotextile special staple fiber where needed

- Geotextile special staple fiber where needed

- Q: Does the geotextile filter cover the geotextile? Or impermeable geotextile?

- Filter the geotextile on the seepage geotextile, when the water from the fine soil into the coarse soil layer, the use of polyester staple acupuncture geotextile good permeability and water permeability, so that the flow through the effective carrying soil Particles, sand, small stone, etc., in order to maintain the stability of soil and water engineering.

- Q: Can geotextiles be used in underground pipe installation?

- Yes, geotextiles can be used in underground pipe installation. Geotextiles are often used as a separation and filtration layer between the soil and the pipe to prevent soil intrusion and ensure proper drainage. They help enhance the performance and longevity of underground pipes by providing stability and preventing clogging.

Send your message to us

PP Woven Fabric/ Ground cover/ Weed Barrier

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords