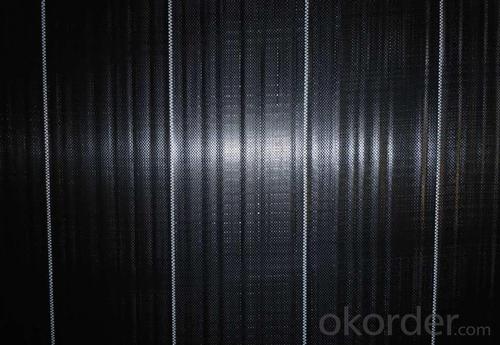

DIY Geotextiles PP Woven Fabric Groundcover Weed Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Geotextiles are composed from synthetic polypropylene/polyester fibres through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration. Type: 1. Wovens & knitted: use various fibre types (e.g. monofilament, multi-filament, split extruded film) in different combinations. 2. Non-wovens: staple or continuous fibres that are heat treated or needlepunched to “fix” fibres relative to each other.

Specification

1) Weight / Mass: 75g/m2-400g/m2 .

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP

5) Color: Black , white , grey, others

6) Certificate: CE/ISO9001, ISO14001 .

7) Manufacturing method: nonwoven / woven.

8) The biggest geotextile manufacturer/factory in China for many years . The equipment is introduced from Germany.

9) This geotextile can be made of polypropylene (PP).

10) The mass is available from 75g/m² to 400g/m² and the width available from 1.0m-8m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber.

Application

Major functions: Separation, filtration, drainage, reinforcement, protection, and liquid barrier

1) Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3 )Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 )Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles improve the performance of geotubes?

- Geotextiles improve the performance of geotubes by providing additional reinforcement and stability. They act as a filtration layer, preventing soil erosion and allowing water to pass through while retaining fine particles. Geotextiles also enhance the strength and durability of geotubes by distributing loads evenly and reducing the risk of punctures or tears.

- Q: Can geotextiles be used in geogrid reinforcement applications?

- Yes, geotextiles can be used in geogrid reinforcement applications. Geotextiles are often used in conjunction with geogrids to provide additional support and stabilization to the soil. The geotextile acts as a separation layer, preventing the intermixing of different soil layers and enhancing the overall performance of the geogrid reinforcement system.

- Q: Long-term exposure to geotextiles on the human body what harm?

- No harm, Huazhi geotextile material answer

- Q: Geotextile price specific how to develop?

- Each type of product in the market before the sale, the pricing will take into account all aspects of the factors, very strict and careful investigation, geotextile is also true. The first is the product quality is the second product specifications and standards to Hongxiang new material short wire geotextile, for example, sub-weight (80-1500g / ㎡), the quality standard is a requirement, divided into non-standard, by White A, Sinochem, ordinary GB, Paul GB, Dahua GB and so on. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: How do geotextiles help with reinforcement of geotextile tubes?

- Geotextiles help with the reinforcement of geotextile tubes by providing stability and strength. They act as a barrier, preventing soil erosion and maintaining the shape and integrity of the tube. The geotextile acts as a filter, allowing water to pass through while retaining soil particles, which helps in soil consolidation and prevents the tube from collapsing. Additionally, geotextiles distribute stress evenly across the tube, enhancing its load-bearing capacity and overall performance.

- Q: How do geotextiles improve the performance of shorelines?

- Geotextiles improve the performance of shorelines by providing erosion control, stabilizing the soil, and enhancing filtration. They act as a barrier against wave energy and currents, preventing the loss of sediment and minimizing erosion. Additionally, geotextiles help to reinforce and stabilize the shoreline, reducing the risk of land subsidence or collapse. Their permeable nature allows water to pass through while trapping sediment, reducing the accumulation of silt and pollutants. Overall, geotextiles play a crucial role in protecting and maintaining the integrity of shorelines.

- Q: Can geotextiles be used in waste storage facility applications?

- Yes, geotextiles can be used in waste storage facility applications. Geotextiles can provide several benefits in waste storage facilities, such as erosion control, filtration, and separation of different layers of waste materials. They can also help to improve the stability and performance of waste storage structures by reinforcing the soil and preventing the migration of fine particles.

- Q: What is the specific use of geotextile construction site? How much is it used?

- From the reinforcement, the role of filtration, I am specializing in the production of geotechnical materials

- Q: I would like to make the beach bigger along the lake in our backyard. I am hoping to do it myself for my husband for father's day. I need suggestions on the best way to do this as a one women team.

- "Quilting fabric" is typically 100% cotton. Quilters prefer to use cotton over other fabrics. Sewing fabric can be any type of fabric ie: cotton, flannel, polyester, knit and others. Using "quilting fabric" is fine for a skirt as cotton is a good choice. I've sewn quite a few of my daughters clothes with it and it wears really well. The variety of patterns and colors is usually fantastic.

- Q: Are geotextiles suitable for use in coastal erosion control?

- Yes, geotextiles are suitable for use in coastal erosion control. They can effectively stabilize soil, prevent erosion, and promote vegetation growth in coastal areas. Geotextiles provide a barrier against wave action and help to retain sediment, reducing the rate of erosion and protecting shorelines from further degradation.

Send your message to us

DIY Geotextiles PP Woven Fabric Groundcover Weed Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords