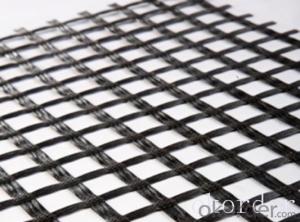

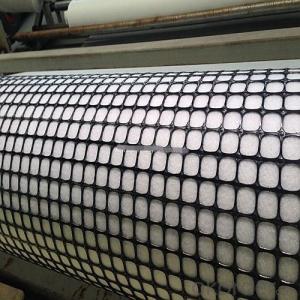

PP Plastic Polypropylene Biaxial Low Elongation Fabric Geotextile Geogrid for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Plastic polypropylene geogrid biaxial

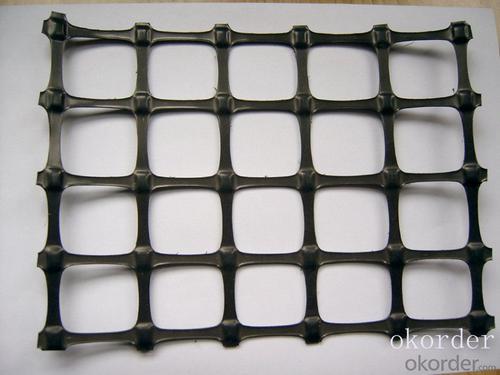

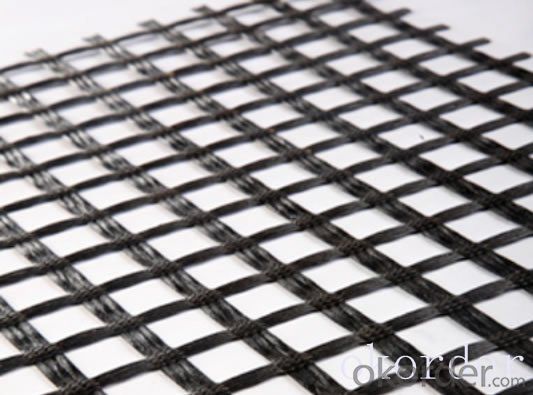

The properties of Biaxial Geogrids, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Production function

1:Tensile strength, high creep degeneration small, it has good flexibility, low elongation at break, and effectively solved the engineering distortion and quite a shift, adapt to the environment soil, and can meet the retaining wall of high grade highway tall role.

2:Effectively improve the bearing the reinforcement embedded locks, bite role, great enhancement the bearing capacity of the foundation, effective constraint of soil lateral displacement, enhance the foundation stable performance.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Heap half a month later in the mound inside dug a tree tree hole, a heavy rain, a region which has two trees in the area of water, to several days of talent, which is normal, please expert advice, More

- Are you geotextile or composite film? Is your waterproofing layer ready? Do not leak?

- Q: Geotextile 300g * 600mm * 300g is how is it?

- No you say 300g * 600mm * 300g this specification of the product, according to reason should be 300g * 0.6mm * 300g product 300g * 0.6mm * 300g product is a composite geomembrane specifications, also known as two cloth a film , Composite geotextile. That is, both sides of the upper and lower sides of a layer of 300g geotextile, the middle folder 0.6mm thickness of the plastic film. Composite geomembrane is to play the role of anti-seepage, generally used for water conservancy project seepage, civil engineering seepage and so on. The geotextile is from the water, reinforcement, protection, and can not achieve the role of anti-seepage. 300g * 0.6mm * 300g composite geomembrane price is generally between 11.5-13 yuan. You can do the next reference.

- Q: We have built a swingset with a built in sandbox. I am looking for geotextile fabric to put under the sandbox to keep weeds & roots out. Any ideas where I can get this from? Local home improvement stores do not stock geotextile fabric. I bought some from a pool supply store for my pool bottom, but they don't sell custom sizes.

- I'm really surprised. All of the Lowe's, Home Depots, etc. that I know of stock landscape barrier fabric, as do all the garden supply shops. If you truly can't find any, carpet works well, as will corrugated cardboard for a season. If the kids use the sandbox a lot, they'll usually keep the weeds down, too.

- Q: What are the considerations for geotextile selection in road rehabilitation projects?

- When selecting geotextiles for road rehabilitation projects, several factors need to be considered. These include the type and severity of the road distress, the traffic volume and load requirements, the soil conditions, and any environmental concerns. Additionally, the geotextile's strength, durability, and compatibility with other materials used in the road rehabilitation process should also be taken into account. Proper consideration of these factors ensures that the selected geotextile will effectively enhance the road's performance and longevity.

- Q: Can geotextiles be used in geothermal energy projects?

- Yes, geotextiles can be used in geothermal energy projects. Geotextiles are often used as a separation and filtration layer in geothermal systems to prevent the mixing of different soil layers and to enhance the flow of fluids within the system. They can also provide reinforcement and stability to the surrounding soil, ensuring the long-term durability of the project.

- Q: What are the different geotextile reinforcement techniques for slopes?

- There are several geotextile reinforcement techniques for slopes, including slope stabilization using geotextile wraps, slope reinforcement with geotextile grids, and slope erosion control using geotextile blankets. These techniques involve the use of geotextile materials to enhance the stability and performance of slopes, preventing erosion and promoting long-term stability.

- Q: How do geotextiles help in reducing soil compaction?

- Geotextiles help in reducing soil compaction by acting as a barrier between the soil and external forces such as heavy machinery or foot traffic. They distribute the load more evenly across the soil surface, reducing the impact and preventing excessive compaction. Additionally, geotextiles can enhance drainage and filtration, allowing water to flow through the soil more easily, which helps in maintaining soil structure and reducing compaction.

- Q: How are geotextiles used in geotechnical engineering?

- Geotextiles are commonly used in geotechnical engineering to provide reinforcement, filtration, separation, and drainage in various construction projects. These permeable fabrics are placed within soil or rock structures to enhance their performance, prevent soil erosion, improve stability, and control water flow. Geotextiles are especially useful in road construction, embankments, retaining walls, landfills, and coastal engineering, as they offer cost-effective solutions and contribute to the sustainability and longevity of these structures.

- Q: Geotextile vertical and horizontal stretching the gap is too much how to adjust

- Geotextile longitudinal and horizontal tensile strength of the gap adjustment, mainly in the carding, laying the net, drawing three links to control, sort out the ratio of Daofu regulation, shop layer, shop curtain speed ratio, Sticks, input and output differences, and so are the cause of a huge gap, the other fiber curl, and so is the key. For the above adjustment, you will find the law. In order to geotextile stretch the vertical and horizontal adjustment equal.

- Q: How do geotextiles contribute to the safety of transportation infrastructure?

- Geotextiles play a crucial role in enhancing the safety of transportation infrastructure by providing soil stabilization, erosion control, and drainage management. They prevent soil movement and erosion, which can undermine the stability of roads, slopes, and embankments. Geotextiles also help improve the load-bearing capacity of the soil, reducing the risk of structural failure or settlement. Additionally, these materials promote effective drainage by allowing water to pass through while filtering out fine particles, preventing waterlogging and soil saturation. Overall, geotextiles contribute to the overall durability, longevity, and safe functioning of transportation infrastructure.

Send your message to us

PP Plastic Polypropylene Biaxial Low Elongation Fabric Geotextile Geogrid for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords