Nilex Nonwoven Geotextile PP Biaxial Geogrid for Civil Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

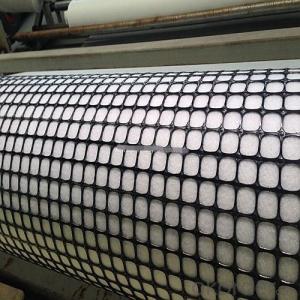

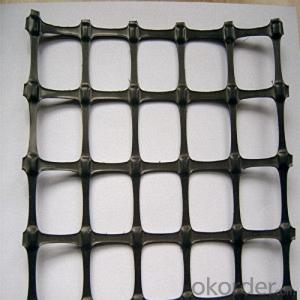

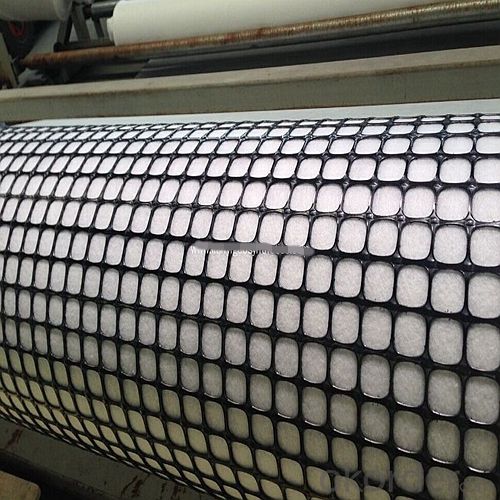

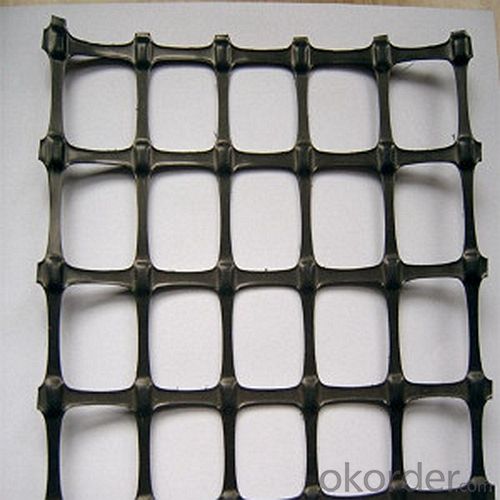

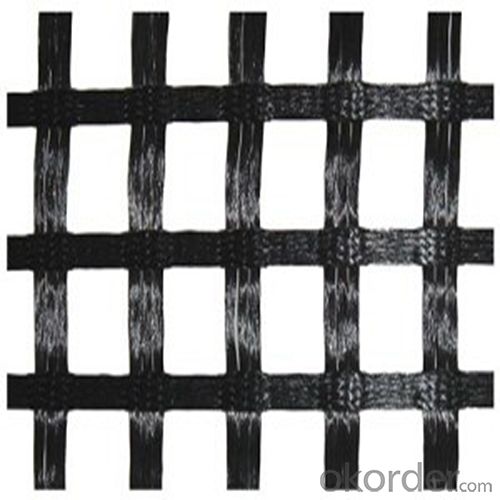

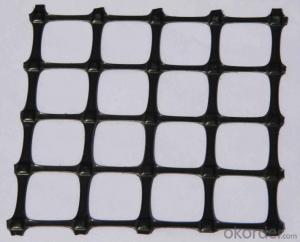

Biaxial polypropylene geogrid

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles commonly used in rainwater harvesting systems?

- Yes, geotextiles are commonly used in rainwater harvesting systems. Geotextiles act as a filtration layer, preventing the entry of debris and sediment into the harvesting system while allowing water to pass through. This helps to maintain the quality of collected rainwater and prevents clogging or damage to the system.

- Q: Can geotextiles be used in road construction?

- Yes, geotextiles can be used in road construction. They are commonly used as a stabilization measure to reinforce the soil, control erosion, and enhance the overall performance of the road. Geotextiles help in distributing the load evenly, improving drainage, and preventing the intermixing of different soil layers. Additionally, they can also provide a barrier to prevent the intrusion of fine particles into the road base.

- Q: Can geotextiles be used in erosion control mats?

- Yes, geotextiles can be used in erosion control mats. Geotextiles are often used as a primary component in erosion control mats to prevent soil erosion by improving stability, drainage, and filtration.

- Q: What are the considerations for geotextile selection in road rehabilitation projects?

- There are several considerations for geotextile selection in road rehabilitation projects. Firstly, the geotextile should have the appropriate tensile strength to withstand the anticipated loads and stresses in the road structure. Additionally, it should have the proper permeability to allow for effective drainage and prevent water accumulation. The geotextile should also be resistant to chemical degradation and have good durability to ensure a long service life. Finally, factors such as cost, availability, and ease of installation should also be taken into account when selecting a geotextile for road rehabilitation projects.

- Q: Can geotextiles be used in railway projects?

- Yes, geotextiles can be used in railway projects. Geotextiles are often used in railway construction and maintenance to improve the stability and performance of the track. They can be used for various purposes such as separation, filtration, reinforcement, and drainage, helping to prevent soil erosion, improve drainage systems, and enhance the overall durability of the railway infrastructure.

- Q: Are geotextiles suitable for use in geogrid reinforced embankments?

- Yes, geotextiles are suitable for use in geogrid reinforced embankments. Geotextiles provide additional strength, stability, and erosion control to the embankments when used in combination with geogrids. They help distribute loads, prevent soil loss, and improve overall performance, making them an ideal choice for reinforcing embankments.

- Q: How are geotextiles affected by biological factors?

- Geotextiles can be affected by biological factors such as the growth of vegetation and the presence of microorganisms. Vegetation can penetrate and grow through geotextiles, reducing their effectiveness in providing separation and reinforcement. In addition, microorganisms can cause degradation of the geotextile material over time, compromising its structural integrity. Therefore, it is important to consider and manage these biological factors when using geotextiles in various applications.

- Q: How do geotextiles improve the stability of slopes?

- Geotextiles improve slope stability by providing reinforcement and erosion control. They are placed within the slope to act as a barrier against soil movement, preventing erosion and enhancing the overall stability of the slope. Additionally, geotextiles help to distribute loads more evenly, reducing the potential for slope failure.

- Q: Will the geotechnical cloth used for highway engineering, geogrid raw materials, routine testing items, parameters which?

- Geotextile main inspection items are: ① Tensile strength: In the tensile test, the specimen until the fracture until the maximum tensile stress is the tensile strength, known in the academic sense of tensile strength. ② elongation: elongation, that is, the percentage of the ratio of the total deformation to the length of the original gauge after the tensile fracture of the specimen. ③ tear strength: it is a thin film or thin film tear resistance of a test method defined in a term. This method is a tear test performed on a special testing machine with a specimen with a predetermined gap. ④ bursting strength ⑤ thickness ⑥ per unit area quality ⑦ permeability coefficient: permeability coefficient, also known as hydraulic conductivity. In an isotropic medium, it is defined as the unit flow rate per unit of hydraulic gradient, indicating the ease with which the fluid passes through the pore skeleton. Geogrids include: appearance, physical properties (including: mass per unit area, amplitude measurement, mesh size determination); mechanical properties (including: strip tensile test, joint / seam wide strip tensile test, sticky Solder joints)

- Q: Google for a long time only geotextile ads! The The Do not know geotextile, drainage board such materials, in what kind of shop which has to sell? Because the building materials market to a circle, people did not sell this thing more

- Retail, then, to the local hardware and electrical city to see. Manufacturers of drainage board geotextile

Send your message to us

Nilex Nonwoven Geotextile PP Biaxial Geogrid for Civil Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords