Polyester Woven Geogrids - PP Biaxial Geogrid for Civil Engineering Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

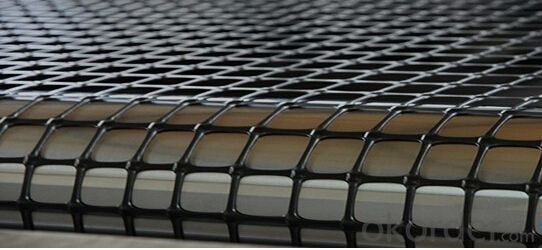

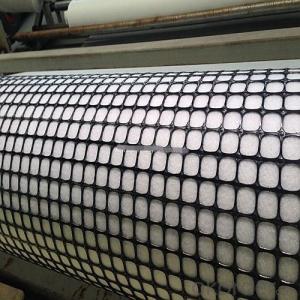

1. Introduction of PP Biaxial Geogrid

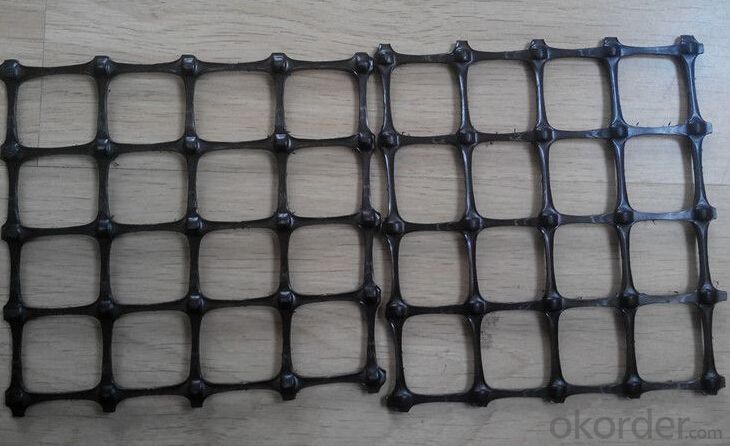

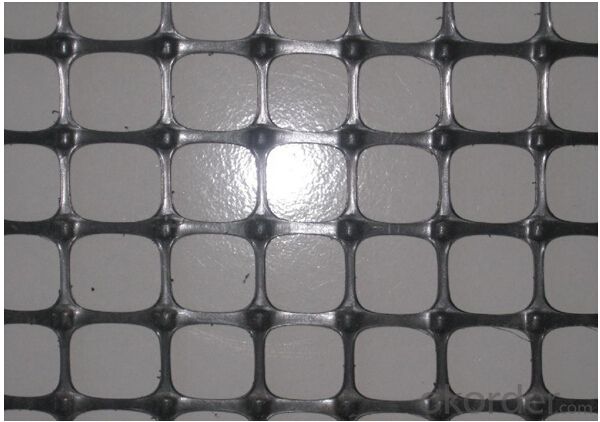

PP Biaxial Geogrid is manufactured from Polypropylene. It is produced through the process of extruding, punching, heating, longitudinal stretching and transverse stretching.

The reinforcing action of PP Biaxial Geogrids lies mainly in confining soil and increasing its shearing resistance by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost. PP Biaxial Geogrids can be used with any kind of mechanical fill material. Two aperture size ranges are available for optimum matching with project fill.

2. Features of PP Biaxial Geogrid

High tensile strength at both longitudinal and transverse direction

3. Application of PP Biaxial Geogrid

Soft foundation reinforcing for highway, railway, slope protecting projects, landfill sites.

4. Technical Data and Specification of PP Biaxial Geogrid

Property | Test Method | TGSG 15-15 | TGSG 20-20 | TGSG 30-30 | TGSG 40-40 | |

Ultimate tensile strength(1) (kN/m) | MD |

ASTM D 6637 | 15 | 20 | 30 | 40 |

CD | 15 | 20 | 30 | 40 | ||

Elongation at maximum load (%) | MD | 13 | ||||

CD | 13 | |||||

Tensile strength at 2 % elongation (kN/m) | MD | 5 | 7.5 | 10.5 | 14 | |

CD | 5 | 7.5 | 10.5 | 14 | ||

Tensile strength at 5 % elongation (kN/m) | MD | 7 | 14 | 21 | 28 | |

CD | 7 | 14 | 21 | 28 | ||

Minimum Carbon Black | % | ASTM D 4218 | 2 | |||

Dimensions

Roll Length(m) | 100/50 |

Roll Width(m) | 2/3.9/3.95 |

5. Loading Quantity for one 40HC.

TGS15-15, 300rolls, 59250m2

TGS20-20, 220rolls, 43450m2

TGS30-30, 144rolls, 28440m2

TGS40-40, 100rolls, 19750m2

6. RFQ:

1) What's your payment terms?

T/T, L/C at sight, etc

2) What's your delivery time?

Within 15-20days against your deposit or original L/C received

3) Can you accept third party test?

Yes, we can accept it totally, SGS, BSJ, etc are no problem for us.

4) Can you provide free samples?

Yes, we can supply but express fees are usually on buyer's account.

- Q: Can geogrids be used in temporary construction haul roads?

- Yes, geogrids can be used in temporary construction haul roads. Geogrids are commonly used in road construction to improve soil stability and reinforcement. They provide effective load distribution and prevent the lateral movement of soil particles, thereby increasing the load-bearing capacity of the road. In temporary construction haul roads, where heavy equipment and frequent traffic are involved, geogrids can be a useful solution to enhance road performance and durability.

- Q: Can geogrids be used in temporary erosion control applications?

- Yes, geogrids can be used in temporary erosion control applications. They are often used to stabilize and reinforce soil in areas prone to erosion, such as construction sites or temporary access roads. Geogrids provide strength and stability to the soil, preventing erosion and promoting vegetation growth.

- Q: How do geogrids improve the stability of slopes?

- Geogrids improve the stability of slopes by providing reinforcement to the soil or rock materials. They are installed within the slope to distribute the applied load over a larger area, reducing stress concentrations. This reinforcement helps to prevent soil or rock movement, enhancing slope stability and reducing the risk of slope failure.

- Q: Polyester warp knitted polyester geogrid and glass fiber geogrid price difference in the price of many components is a ghost?

- Polyester warp knitted polyester coating is PVC glue, glass fiber geogrid is that sensitive asphalt rubber. An anti-corrosion, a alkali resistance. Material is not the same, the appearance is not difficult to distinguish between experts

- Q: What are the limitations of geogrids?

- Geogrids have a few limitations. Firstly, they are not suitable for all types of soil and terrain conditions. They are most effective in soils with good particle interlock and cohesion. Secondly, geogrids are not effective in situations where there is high water flow or erosion potential as they do not provide sufficient protection against these forces. Additionally, geogrids may have limited strength in certain applications, such as heavy load-bearing scenarios, and may require additional reinforcement. Lastly, the installation and maintenance of geogrids can be complex and costly, requiring skilled labor and regular inspections to ensure proper functioning.

- Q: What is the recommended overlap distance for geogrid seams?

- The recommended overlap distance for geogrid seams typically ranges from 6 to 12 inches.

- Q: Physical characteristics of geogrid construction method

- 2, check the geogrid reinforced asphalt pavement or cement: Geogrid laying layer at the bottom of asphalt or cement, can reduce rutting depth, prolong the fatigue life of the pavement, but also can reduce the asphalt or cement pavement thickness, in order to save costs.3, one-way geogrid for reinforcing the dam and road slope and retaining wall: the traditional embankment especially filling high embankment filling and often need to shoulder edge easy compaction, resulting in slope rainwater invasion, collapse phenomenon, at the same time with a gentle slope, covers an area of large, retaining wall have the same problem with Geogrid embankment slope or retaining wall reinforcement can be reduced by two points a area, prolong service life, reduce the cost of 20 - 50%.4, one-way geogrid to reinforce the River seawall: made of stone cage, with the grid and use, prevent the dam washed collapse, stone cage is permeable and can reduce the impact of the waves, prolong the life of the dam, save manpower, shorten the construction period.5, one-way geogrid for processing landfills: Geogrid and other synthetic materials using a combination of Soil Treatment Landfill, can effectively solve the problem of gas emissions derived from the uneven settlement of foundation, and can improve the landfill to maximize storage capacity.6, one-way geogrid special purpose: low temperature resistance. Low temperature resistance of geogrid Lianyi, at - 45 C and 50 C - repeated 200 cycles, the performance indexes meet the requirements, and has been applied to the test of the Qinghai Tibet railway, the North less ice permafrost and ice rich permafrost and ice rich permafrost bad geology.

- Q: How do geogrids improve the performance of reinforced soil structures?

- Geogrids improve the performance of reinforced soil structures by providing additional tensile strength and stability. These materials enhance the load-bearing capacity of the soil, prevent movement and settlement, and distribute the applied loads more evenly. Geogrids also minimize the potential for soil erosion and improve the overall durability and longevity of the reinforced structure.

- Q: Can geogrids be used in temporary construction access mats for environmentally sensitive areas?

- Yes, geogrids can be used in temporary construction access mats for environmentally sensitive areas. Geogrids are highly durable and can provide stabilization and support to heavy construction equipment while minimizing environmental impacts. They distribute the load more evenly, reducing soil compaction and preventing damage to the sensitive ecosystem. Additionally, geogrids can be easily removed after the construction is complete, leaving minimal disturbance to the area.

- Q: Can geogrids be used in coastal erosion control?

- Yes, geogrids can be used in coastal erosion control. Geogrids are often employed as a reinforcement material to stabilize soil and prevent erosion in coastal areas. They can be used to strengthen slopes, retain beach or dune materials, and provide stability to coastal structures like seawalls or revetments. Geogrids are designed to withstand the harsh coastal environment and can effectively reduce the impact of wave and tidal action on the shoreline, making them a valuable tool in coastal erosion control efforts.

Send your message to us

Polyester Woven Geogrids - PP Biaxial Geogrid for Civil Engineering Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords