PP Fiberglass Geogrid Geocells for Road Construction with High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

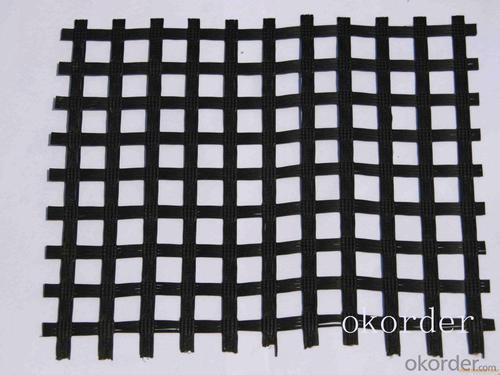

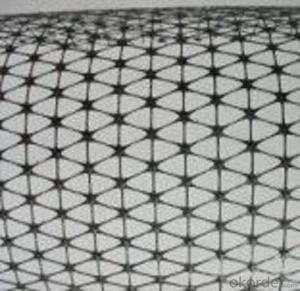

CNBM offers geogrids for base reinforcement. They are manufactured by welding or stitching together two layers of extruded, polypropylene, flexible geogrids to create a continuous sheet that will not separate.

Road bed reinforcement-it can effectively allocate and disperse load,improve the stability and load capacity of road bed and extend the useful lfe of road

1)fiberglass geogrid with CE certificate

2)Materials:fiberglass

3) Tensile strength:MD/CD:30 ~ 200kn/m

4)WIdth:1 ~ 6m

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is a one-way plastic geogrid

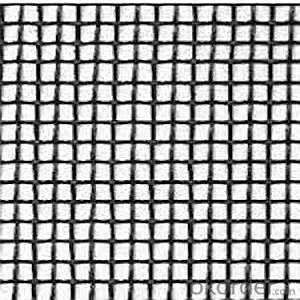

- The plastic geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching, and it can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

- Q: Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are flexible and durable materials that can reinforce soil and improve its stability. In seismic zones, where the ground is prone to shaking and instability during earthquakes, geogrids can effectively enhance soil resistance to lateral movement, reduce soil liquefaction, and provide greater overall stability to structures. Their ability to distribute loads and increase soil confinement makes them highly suitable for use in seismic zones.

- Q: Are geogrids suitable for reinforcing steep slopes?

- Yes, geogrids are suitable for reinforcing steep slopes. Geogrids are commonly used in various civil engineering applications, including slope stabilization. They provide additional stability by distributing the forces exerted by the soil and preventing soil erosion. Geogrids are lightweight, flexible, and have high tensile strength, making them an ideal choice for reinforcing steep slopes and preventing potential landslides.

- Q: What is the typical weight of a geogrid roll?

- The typical weight of a geogrid roll can vary depending on its size and material, but it typically ranges from 50 to 100 pounds.

- Q: Physical characteristics of geogrid construction method

- One way tensile geogrid1, is a kind of polymer as the main raw material, adding anti UV, anti aging agent must, after the original tensile distribution chain shaped molecules scattered re aligned linear, pressure into a sheet by extrusion and punching network rules, high strength geosynthetics and longitudinal stretch into the. In this process, the polymer is in a directional linear state and a long elliptical structure with uniform distribution and high node strength is formed. This structure has very high tensile strength and tensile modulus, tensile strength reached 100-200Mpa, close to the level of low carbon steel, much better than the conventional or existing reinforced materials, especially in the company of such products is more than the international level of the early high (elongation at 2% - 5%) tensile strength and tensile modulus. A chain system that provides an ideal force for the soil to bear and spread. The tensile strength of the product (>150Mpa), to adapt to a variety of soil, is widely used in the reinforcement material. Unidirectional geogrid use:Unidirectional geogrid, 1 unidirectional Geogrid Reinforced Soft Foundation: Geogrid can rapidly improve the bearing capacity of the foundation and development of settlement control, can effectively load to the base of a wider upper limit on the road side, thereby reducing the base thickness, reduce project cost, shorten the construction period, prolong the service life.

- Q: Can geogrids be used for reinforcement in embankments and dams?

- Yes, geogrids can be used for reinforcement in embankments and dams. Geogrids are high-strength synthetic materials that are commonly used in civil engineering and construction projects to increase the stability and strength of soil structures. By incorporating geogrids into embankments and dams, they can effectively reinforce the soil, reduce settlement, and improve overall performance and durability of these structures.

- Q: How do geogrids improve the performance of mechanically stabilized walls?

- Geogrids improve the performance of mechanically stabilized walls by providing reinforcement and enhancing the stability of the wall structure. They act as a support system, increasing the tensile strength of the soil and preventing it from sliding or collapsing. The geogrids distribute the loads exerted on the wall more evenly, reducing the pressure on the wall face and minimizing the risk of structural failure. Additionally, they enhance the overall durability and longevity of the wall system by preventing soil erosion and promoting proper drainage.

- Q: I asked what the raw materials needed for the production were, for example, what the green mesh was made of

- Plastic geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other additives by extrusion become composite high strength tensile band, and surface roughness is embossed, high strength reinforced Geotextile

- Q: What is the significance of each index

- The slope on shop, should maintain a certain degree of tightness.Two)Geosynthetics shall be placed on each side of the embankment for a certain length, and shall be folded and wrapped in compacted fillOn the plane, the exposed part of the earth is covered by the soil.Three)When the joint of geosynthetics is used, the lap length should beThree hundred

- Q: What are the criteria for Geogrid?Would like to know the price of Geogrid and geogrid manufacturers

- Geogrid is in the extrusion of polymer plate (raw materials are mostly polypropylene or high-density polyethylene) on the punching

Send your message to us

PP Fiberglass Geogrid Geocells for Road Construction with High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords