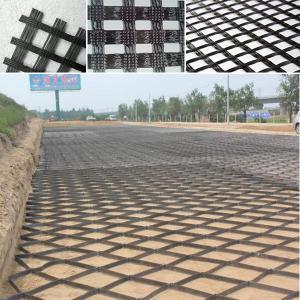

Vegetated Biaxial PP Geogrid for Embankment Stabilization/Slope Reinforcement/Highway/Roadway/Bridge with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic PP Geogrids Introduction

It is mainly used in highway and railroad to reduce the subsiding difference ofthe roadbed and bridgehead, lower the vibration of the vehicles and theroadbed, slower the roadbed structure distortion to guarantee the security and comfort.

To lay the geogrid in the backfill soil can increase the shearing strength and the whole character in middle terms, reduce the mid-term filling quantity, make the soft base more convenient, lower the construction cost.

When used in the dam design, it can be as the muscle structure to improve the bearing distortion performance of the dam to avoid breaking.

Plastic PP Geogrids Features

High tensile strength

Low elongation

Excellent temperature resistant

Good anti-aging

Good alkali-resistance

Plastic PP Geogrids Specifications

tensile strength:15KN/m-50KN/m

width:4m

length:50m

color:black

pp geogrid ,biaxial geogrid,uniaxial geogrid

Item | Art. No. | 010301 | 010302 | 010303 | 010304 | 010305 |

Specs | 15-15 | 20-20 | 30-30 | 40-40 | 45-45 | |

Unit weight,g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | 550±50 | |

Width,m | 4.0+0.2/-0 | |||||

Tensile strength(MD), kN/m≥ | 15 | 20 | 30 | 40 | 45 | |

Tensile strength (CD),kN/m≥ | 15 | 20 | 30 | 40 | 45 | |

Elongation(MD),%≤ | 15 | |||||

Elongation(CD),%≤ | 13 | |||||

Tensile strength at 2% strain(MD),kN/m≥ | 5 | 7 | 10.5 | 14 | - | |

Tensile strength at 2% strain(CD),kN/m≥ | 5 | 7 | 10.5 | 14 | - | |

Tensile strength at 5% strain(MD),kN/m≥ | 7 | 14 | 21 | 28 | - | |

Tensile strength at 5% strain(CD),kN/m≥ | 7 | 14 | 21 | 28 | - | |

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement to the soil structure. They are designed to distribute the forces exerted by the soil and help prevent erosion and slope failure. Geogrids act as a stabilizing mechanism by increasing the strength of the levee, reducing the potential for settlement, and enhancing its overall stability.

- Q: How do geogrids help in pavement design?

- Geogrids help in pavement design by providing reinforcement and stabilization to the pavement structure. They are placed within the layers of the pavement to distribute and restrain the loads, enhancing the overall strength and durability of the pavement. Geogrids also help in reducing the occurrence of cracks and rutting, extending the lifespan of the pavement.

- Q: How do geogrids improve the performance of soil retaining structures?

- Geogrids improve the performance of soil retaining structures by providing reinforcement and stability to the soil. They distribute the applied loads more evenly, reduce soil movement and prevent the occurrence of sliding or failure. Additionally, geogrids increase the bearing capacity of the soil, enhance drainage, and improve overall durability and longevity of the retaining structures.

- Q: How do geogrids improve the performance of geotextile sediment retention tubes?

- Geogrids improve the performance of geotextile sediment retention tubes by providing additional structural support and stability. They reinforce the geotextile fabric, preventing it from sagging or collapsing under the weight of sediment and water pressure. This reinforcement helps the tubes maintain their shape and integrity, enhancing their effectiveness in retaining sediment and preventing erosion.

- Q: Can geogrids be used in shoreline erosion control?

- Yes, geogrids can be used in shoreline erosion control. Geogrids are commonly used in coastal engineering projects to stabilize the soil and prevent erosion by reinforcing the shoreline. They are effective in providing structural support and preventing the loss of sediment, thereby reducing erosion and protecting the coastline.

- Q: What is the lifespan of a geogrid?

- The lifespan of a geogrid can vary depending on factors such as the quality of the material, environmental conditions, and the level of stress it experiences. However, with proper installation and maintenance, geogrids can typically have a lifespan of 20 to 50 years.

- Q: What are the factors that affect the installation time of geogrids?

- There are several factors that can affect the installation time of geogrids. First and foremost, the size and complexity of the project play a significant role. Larger and more complex projects may require more time for planning, preparation, and execution. The type and condition of the soil also impact installation time. Soft or loose soils may require additional stabilization measures before the geogrids can be installed, which can extend the overall installation duration. Similarly, rocky or hard soils may require specialized equipment or techniques, which can also increase the installation time. The availability and accessibility of the site can also affect installation time. If the site is difficult to reach or has limited space for equipment and materials, it can slow down the installation process. Additionally, factors such as weather conditions, environmental restrictions, and safety considerations can further influence the installation time. Lastly, the experience and expertise of the installation team can greatly impact the efficiency and speed of the installation process. A skilled and experienced team can streamline the installation and overcome any challenges more effectively, reducing the overall installation time.

- Q: Can geogrids be used in reinforcement of underground storage tanks?

- Yes, geogrids can be used in the reinforcement of underground storage tanks. Geogrids are commonly used in soil stabilization and reinforcement applications, and they can provide additional support and enhance the structural integrity of underground storage tanks. They are typically installed around the tanks to distribute loads, reduce soil movement, and prevent potential damage or failure.

- Q: Which is the high price of steel plastic geogrid and fiberglass geogrid

- If you take the worst plastic steel and the best glass fiber ratio, the latter price is high

- Q: See details of the application of design code for railway embankment geosynthetics TB10018-2006

- See details of the application of design code for railway embankment geosynthetics TB10018-2006

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Vegetated Biaxial PP Geogrid for Embankment Stabilization/Slope Reinforcement/Highway/Roadway/Bridge with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords