HPA Geocells Never Run Multiaxial Plastic Soil Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

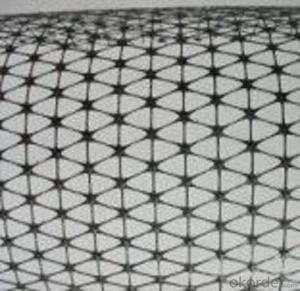

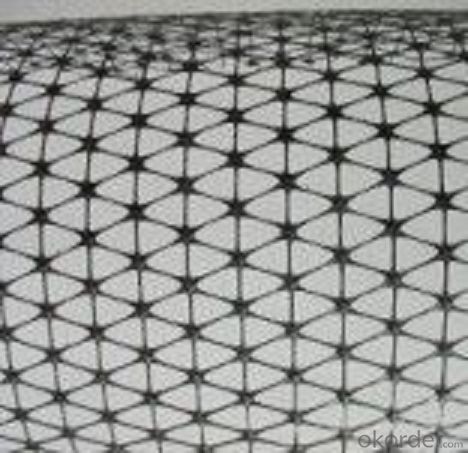

Multiaxial geogrid , made of polypropylene plate , is extruded into sheet and then punched into regular mesh and finally streched into the whole tensile geogrid , triangular mesh is combined orgnaticlly.

Product introduction:

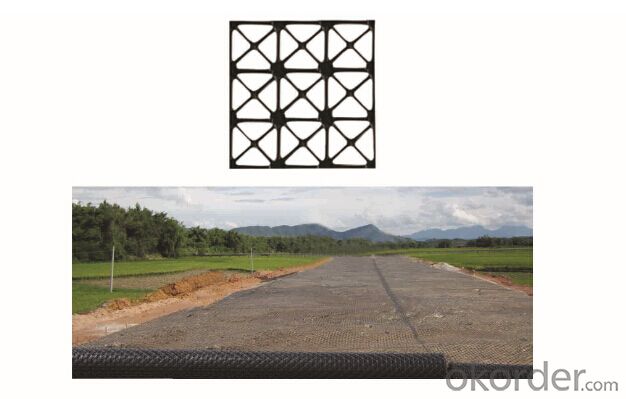

three axial triangular grid is a new kind of geotechnical reinforcement materials, the latest development because of its stable structure, triangle, two-way than one-way gratings have more reasonable stability, and can bear the load of multiple directions, at the same time more effectively play the role of distributed load, is the ideal choice of the geotechnical engineering reinforcement reinforcement.

Triangular grid main advantages:

1. With the most stable triangular structure, stress is not easy to occur structural deformation;

2. Able to carry more direction load at the same time, not easy to happen node torsion failure;

3. Because of its rectangular section, is not easy to produce and soil slip, the reinforcement effect is better;

4. Because of the node is larger than two-way grille, efficiency is higher, so the node node is not easy to damage;

More than 5. And because of muscle common node, so more saving materials, are more energy efficient.

Three axial triangular grid performance specification (tentative)

The geometric requirements

SAS15

SAS20

SAS25

SAS30

1) the rib length (mm)

32

32

32

32

2) node thickness (mm)

2.2

3

3.8

4.5

3) the rib section shape

rectangular

rectangular

rectangular

rectangular

4) mesh shape

triangle

triangle

triangle

triangle

1) node transfer efficiency (%) or higher

95

95

95

95

2) low strain when the radial tensile modulus (KN/m, @ 0.5% strain) or greater

225

375

430

475

3) quality control tensile modulus (KN/m, @ 2%) or greater

170

230

280

340

4) the mesh stiffness (kg - cm/deg, @ 5.0 kg - cm) or greater

3.0

3.6

5.6

7.8

Carbon black content of p

2%

Note: 1) node efficiency namely load transfer capacity, expressed as a percentage of maximum tensile strength;

2) is according to the radial tensile modulus ISO10319:1996 by measuring the axial plane of the tensile modulus is measured;

3) quality control according to tensile modulus ISO10319:1996 tensile measurement;

4) the mesh stiffness in the horizontal plane, namely to 225 mmx225mm sample center node by applying a torque measurement. Type TG301 geogrid is by our company on the basis of single and double to geogrid, complement each other, independent research and development of low consumption, environmental protection new grille. Type TG301 geogrid is made of PP material by rotating the nose out of a natural law with a mesh plate is arranged, after orientation stretching a forming type terminal grille, we fully consider the in recent years -- new method for calculating the ground settlement, the secant modulus method, repeated calculation with nanjing iwhr geotechnical engineering research institute, many times

Do the destructive and load test to prove:

Type 1. TG301 geogrids stress load, force to disperse bearing rib direction, uniform load distribution

2. The mechanical properties of the single and double to more stable, geogrid tensile modulus and secant durable ability is stronger, its unique network structure is more suitable for the conditions under different environmental stress.

3. The node is gangsu PP welding gratings have absolute stability.

- Q: Can geogrids be used in embankment stabilization?

- Yes, geogrids can be used in embankment stabilization. Geogrids are commonly used in civil engineering applications to provide reinforcement and stability to soil structures, including embankments. They help to distribute loads more evenly, reduce soil movement, and increase overall stability.

- Q: Can geogrids be used in retaining walls for industrial facilities?

- Yes, geogrids can be used in retaining walls for industrial facilities. Geogrids are commonly used in retaining walls to increase their stability by providing soil reinforcement. They help distribute the forces exerted by the retained soil, making them suitable for use in retaining walls for industrial facilities where there may be higher loads and potentially unstable soil conditions.

- Q: Can geogrids be used in slope stabilization for railway embankments with high water table conditions?

- Yes, geogrids can be used in slope stabilization for railway embankments with high water table conditions. Geogrids are commonly used in such situations to reinforce and stabilize the soil, preventing erosion and maintaining the integrity of the slope. Their high tensile strength and ability to distribute loads make them suitable for railway embankments with high water table conditions.

- Q: How many square meters of geogrid?

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: How do geogrids enhance the stability of railway track embankments?

- Geogrids enhance the stability of railway track embankments by providing additional reinforcement and preventing soil erosion. They improve load distribution, increase bearing capacity, and reduce settlement, ultimately ensuring the long-term stability of the embankment.

- Q: One-way plastic geogrid TGDG120 how qualified

- D unidirectional plastic geogrid 120KN

- Q: What are the factors that affect the creep behavior of geogrids?

- There are several factors that can affect the creep behavior of geogrids, including the type and quality of the geogrid material, the magnitude and duration of applied load, environmental conditions such as temperature and moisture, and the installation and confinement methods used. These factors can influence the long-term deformation and performance of geogrids, making it crucial to consider them in design and engineering applications.

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners in landfill covers?

- Yes, geogrids do provide reinforcement to geosynthetic asphalt liners in landfill covers.

- Q: What is the profit margin of the production of Geogrid

- If the product is supplied in accordance with the specifications required by the contractor

- Q: Can geogrids be used in soil reinforcement for landslide mitigation?

- Yes, geogrids can be used in soil reinforcement for landslide mitigation. Geogrids are commonly used to enhance the stability and strength of soil, including in slope stabilization and landslide prevention. They are placed within the soil mass to provide reinforcement and improve its load-bearing capacity, reducing the risk of landslides.

Send your message to us

HPA Geocells Never Run Multiaxial Plastic Soil Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords