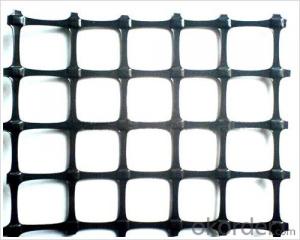

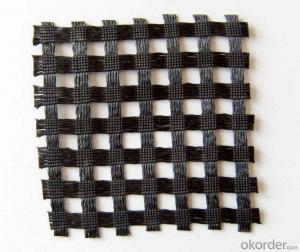

Base Reinforcement Geogrids - Tensar Biaxial Plastic Geogrid Prices

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

Type: Plastic geogrid

Material: High-density polyethyle

Strength: TGSG15KN-TGSG60KN

Width:1m-6m

Roll length: 50m-100m

Color: Black or at your request.

Temperature range:-60oC -- +60oC

Lifetime: more than 50 years

Executive standard:GB/T 17689-2008

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Geogrid Show:

- Q: The price of the type of geogrid manufacturers is the best phone

- Thermal stability - the melting temperature of the glass fiber is above 1000 DEG C, which ensures the stability of the fiberglass geogrid in the paving operation.

- Q: meters. Material: tgsg. This section of subgrade for soft soil foundation (water) what is the purpose and principle of this treatment? Seeking answers experienced master change, or in the design the unit did. Thank you. Do a detailed description of indebted forever. My understanding is...Geogrid width of 3 meters, the berm soil subgrade body laying 1.4 meters, laying 1.6

- The main purpose of filling subgrade is to use geogrid, which is to prevent the longitudinal cracking and sliding. As for Geogrid, it can not directly stabilize the slope, but also rely on geotextile wrapped. As for the soaking embankment, in addition to the use of Geogrid and geotextile, but also consider the problem of slope protection (such as stone, concrete surface etc.).Geogrid is usually used to fill the embankment with high height, in order to play a role. Also, you said that the protection of the ramp laying 1.4 meters, the laying of the roadbed in the area of 1.6 meters, these are trivial, can only play a part of the role of little. See you use the material is plastic geogrid, this is the worst kind of material, the strength is very low. Small size, low strength, not as good as the use of woven bags stacked slope. I guess this is a low grade road

- Q: How do geogrids compare to other soil reinforcement methods?

- Geogrids are a highly effective soil reinforcement method that offers several advantages over other techniques. Unlike traditional methods like retaining walls or soil nails, geogrids are lightweight and easy to install, making them a cost-effective solution. Geogrids also provide excellent tensile strength and stability, increasing the load-bearing capacity of soil and preventing erosion. Additionally, geogrids are flexible and adaptable, allowing for better distribution of load and accommodating ground movements. Overall, geogrids are a superior choice for soil reinforcement due to their versatility, durability, and cost-efficiency.

- Q: Can geogrids be used for reinforcement in embankments and dams?

- Yes, geogrids can be used for reinforcement in embankments and dams. Geogrids are high-strength synthetic materials that are commonly used in civil engineering and construction projects to increase the stability and strength of soil structures. By incorporating geogrids into embankments and dams, they can effectively reinforce the soil, reduce settlement, and improve overall performance and durability of these structures.

- Q: Who knows how much the staggered distance of the lap joint is

- Seam stagger distance is greater than 1 meters, because the joints are relatively weak.

- Q: How do geogrids help with slope stabilization?

- Geogrids help with slope stabilization by providing reinforcement and increasing the stability of soil or rock slopes. They are placed within the slope to distribute the forces acting on it and prevent slope failure. The geogrids act as a barrier, reducing erosion and soil movement, while also enhancing the overall strength and load-bearing capacity of the slope.

- Q: Can geogrids be used in shoreline protection projects?

- Yes, geogrids can be used in shoreline protection projects. Geogrids are often used to reinforce soil and prevent erosion in various applications, including shoreline protection. By providing additional strength and stability to the soil, geogrids can help to prevent the erosion of the shoreline and protect it from the damaging effects of waves and currents.

- Q: Can geogrids be used in reinforcement of coastal structures?

- Yes, geogrids can be used in the reinforcement of coastal structures. Geogrids are commonly used in coastal engineering to enhance the stability and strength of structures such as seawalls, revetments, and breakwaters. They provide additional reinforcement by improving soil cohesion and preventing erosion, thus increasing the durability and resilience of coastal structures against wave action and other environmental forces.

- Q: What are the different types of geogrids available?

- There are several different types of geogrids available, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids have strength in one primary direction and are often used for soil reinforcement and slope stabilization. Biaxial geogrids have strength in two directions and are commonly used for pavement stabilization and ground reinforcement. Triaxial geogrids have strength in three directions and are typically used for heavy-duty applications such as retaining walls and embankments.

- Q: What are the different testing methods for geogrids?

- There are several different testing methods for geogrids, including tensile strength testing, aperture size testing, creep testing, and junction efficiency testing. Tensile strength testing measures the maximum load a geogrid can withstand before breaking, while aperture size testing determines the size of the openings in the geogrid to ensure they meet the required specifications. Creep testing evaluates the geogrid's ability to maintain its strength over time under constant load, and junction efficiency testing assesses the strength of the connections between the geogrid's intersecting strands. These testing methods help ensure the quality and performance of geogrids in various applications.

Send your message to us

Base Reinforcement Geogrids - Tensar Biaxial Plastic Geogrid Prices

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords