High Tensile Geogrid Plastic Geogrid for Road Construction Geocells

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

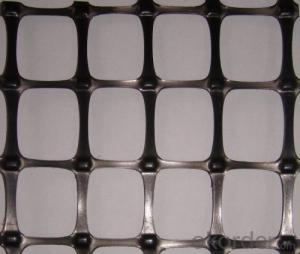

Specifications of Geogrid:

High tensile geogrid

1.Tensile strength: 15~100KN/M

2.Color:black and etc

3.Material:PP/PE

4.Certificate:CE/ISO9001,14001

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

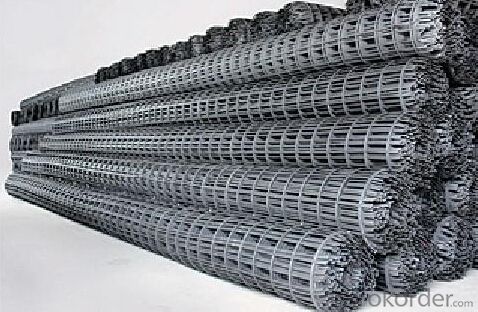

Geogrid Show:

- Q: Can geogrids be used in reinforcement of concrete structures?

- Yes, geogrids can be used in the reinforcement of concrete structures. Geogrids are commonly used as a reinforcement material in various civil engineering applications, including the reinforcement of concrete structures. They are designed to improve the strength, stability, and durability of concrete by providing additional reinforcement and distributing loads more evenly. Geogrids can be embedded within the concrete or placed between layers to enhance the structural performance and prevent cracking or failure.

- Q: Can geogrids be used in construction of temporary access roads over soft ground?

- Yes, geogrids can be used in the construction of temporary access roads over soft ground. Geogrids are often used in civil engineering and construction projects to reinforce and stabilize soil, making them an ideal solution for temporary roads built on soft or unstable ground. The geogrids provide additional support and distribute the load evenly, reducing the risk of sinking or deformation.

- Q: Dimensions of U shaped steel nails for geogrids

- U type nails, like the letter U, geogrid generally 0.6 multiplied by 80. You can also process.

- Q: What are the factors that affect the creep behavior of geogrids?

- The factors that affect the creep behavior of geogrids include the type and quality of the material used in the geogrid, the magnitude and duration of the applied load, the environmental conditions such as temperature and moisture, and the installation and construction techniques employed.

- Q: What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of geogrid used can significantly impact the overall cost. Higher quality geogrids may be more expensive but can provide better reinforcement, leading to longer-lasting and more cost-effective structures. Additionally, the design and engineering of the structure play a crucial role. Properly designed structures that consider factors such as soil conditions, loading requirements, and anticipated lifespan can ensure optimal performance and cost-effectiveness. The construction process and techniques employed also influence the cost-effectiveness. Efficient construction methods, skilled labor, and effective project management can minimize costs and maximize the durability and longevity of the geogrid-reinforced structure. Lastly, the maintenance and monitoring of the structure are essential. Regular inspections and timely repairs, if needed, can prevent costly damages and extend the lifespan of the structure, ultimately enhancing its cost-effectiveness.

- Q: How many Chinese geogrid manufacturers? How many famous

- In foreign markets, the high level of the grid, it is basically the competition with TANSER

- Q: How do geogrids enhance the stability of mechanically stabilized earth walls?

- Geogrids enhance the stability of mechanically stabilized earth walls by providing reinforcement and distributing the applied loads throughout the soil mass. They increase the tensile strength of the soil, preventing excessive lateral movement or deformation. This reinforcement helps to resist the forces exerted by the retained soil, improving the overall stability and performance of the wall.

- Q: What is the difference between plastic geogrid and grid

- Geogrid is suitable for various kinds of dams and subgrade reinforcement, slope and tunnel wall reinforcement. Large airport, parking lot, wharf freight yard and other permanent bearing foundation reinforcement.

- Q: Are there any environmental concerns associated with geogrids?

- Yes, there are some environmental concerns associated with geogrids. For instance, the production of geogrids may require the use of non-renewable resources, such as petroleum-based materials. Additionally, the disposal of geogrids after their useful life can contribute to waste generation. However, when used properly and in accordance with environmental guidelines, geogrids can offer numerous benefits for soil stabilization and erosion control, making them a valuable tool in sustainable construction practices.

- Q: What are the long-term performance characteristics of geogrids?

- The long-term performance characteristics of geogrids include excellent resistance to chemical and biological degradation, high tensile strength, stability, and durability. Geogrids are designed to provide long-lasting reinforcement to soil structures, retaining walls, and roadways, maintaining their effectiveness and integrity over many years of use.

Send your message to us

High Tensile Geogrid Plastic Geogrid for Road Construction Geocells

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords