High Strength PP Geogrid Geocells for Erosion Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PP/HDPE Uniaxial Geogrid:

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Features of PP/HDPE Uniaxial Geogrid:

With high tensile strength and tensile modulus

Application of PP/HDPE Uniaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

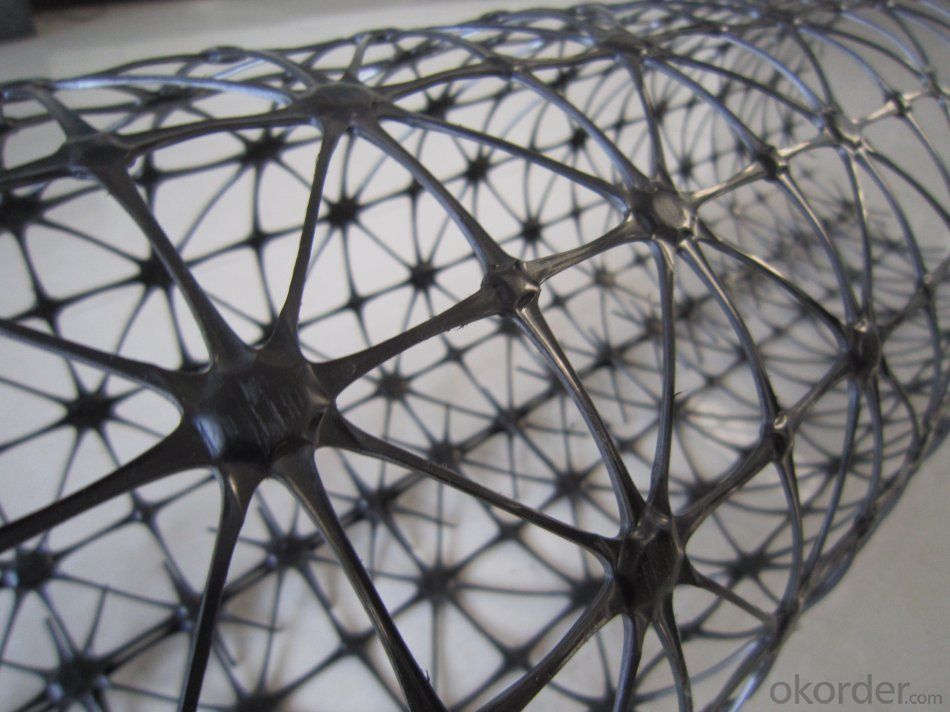

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

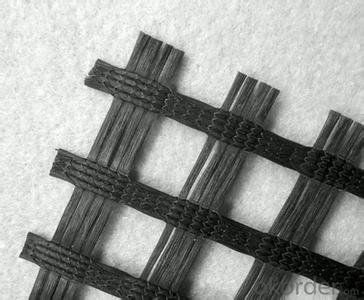

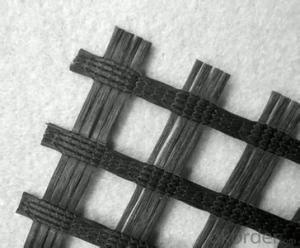

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What is a geogrid?

- A geogrid is a type of geosynthetic material that is used to reinforce soil or other materials in civil engineering applications. It is typically made of polymer materials and has a grid-like structure that provides tensile strength and enhances the stability of the soil or other materials it is placed within.

- Q: Can geogrids be used in erosion control applications?

- Yes, geogrids can be used in erosion control applications. Geogrids are commonly used to reinforce soil and prevent erosion by providing stability to the ground. They help to distribute loads, improve soil retention, and increase the resistance to erosion caused by water or wind.

- Q: Introduction of steel plastic grille

- Construction technology of steel plastic grille

- Q: Who knows how much the staggered distance of the lap joint is

- The staggered distance of the lap joint shall not be less than 300 mm. The concrete specification (geotextile laid overlapping: when) using geotextile as filter layer, should be laid in place in the bottom and sides of the trench wall, soil and reserve covering the top required fabric, straighten ride close to the lower layer, all vertical or horizontal joints should be staggered alternately. The lap length shall not be less than 300MM.A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: Glass steel grille is how to produce

- Production process of FRP grid:Preparation of mold - Preparation of mixed resin - glass fiber yarn - (or at the same time) pouring resin and exhaust bubble - mold heating, product curing - mold - finishing - Inspection packaging.

- Q: Are geogrids resistant to fire?

- No, geogrids are not typically resistant to fire. They are primarily used for soil stabilization and reinforcement purposes and do not possess inherent fire-resistant properties.

- Q: Are geogrids suitable for erosion control on riverbanks?

- Yes, geogrids are suitable for erosion control on riverbanks. Geogrids are commonly used in erosion control applications due to their high tensile strength and ability to reinforce soil. They help stabilize the soil, prevent erosion, and promote vegetation growth, making them an effective solution for protecting riverbanks from erosion.

- Q: Three how much is the price of Geogrid

- Supply of geotechnical materials, such as geogrid.

- Q: What are the differences between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one direction, making them ideal for applications that require reinforcement in a single direction. Biaxial geogrids, on the other hand, have strength and stiffness in both directions, allowing them to provide reinforcement and stability in multiple directions. This makes biaxial geogrids more versatile and suitable for a wider range of applications, including soil stabilization, slope reinforcement, and retaining wall construction.

- Q: What is the effect of temperature on geogrid properties?

- The effect of temperature on geogrid properties can vary depending on the specific material and design of the geogrid. In general, higher temperatures can cause the geogrid to expand and become more flexible, which can result in increased tensile strength and improved load-bearing capacity. However, extreme temperatures, either high or low, can also lead to a decrease in geogrid properties, such as reduced stiffness and reduced resistance to deformation. Therefore, it is important to consider the temperature conditions in which the geogrid will be used to ensure optimal performance and longevity.

Send your message to us

High Strength PP Geogrid Geocells for Erosion Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords