Aluminum F Molding Extrusion Powder Coating Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

POWDER COATING ALUMINUM PROFILE

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

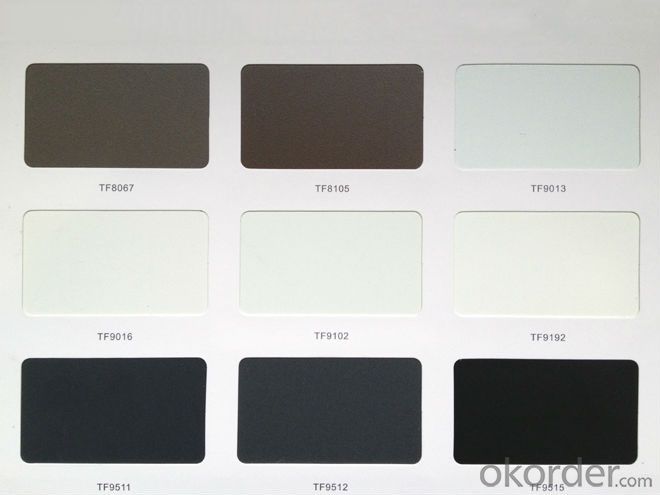

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: Dongguan industrial aluminum profile manufacturers which good?

- Explain as follows: preparing goods, recruit a few operator, big online promotion can be opened. Those who are often hurt are our buyers. Miss wiring mostly do not know how to use, only know the unit price. How to use to meet customer needs; how to make the most cost-effective; in different venues that kind of connection is the best; these are they can not answer accurately. Only know the cheapest and recommended profile connection the cheapest; this connection is the lowest cost, but the cost of artificial, a connection is the weakest, aluminum convenience wouldn't be reflected, and will bring much trouble for the future reconstruction. But the wiring girl will push it one way.Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, recommended: https://cowing2010.1688 /, own also users, have very rich experience, have a good understanding and knowledge of the quality and performance of products, will be recommended for the customer needs better product price selected, convenient and practical accessories.

- Q: Are aluminum profiles recyclable and can they be used again in flooring applications?

- <p>Yes, aluminum profiles can be recycled and reused in flooring applications. Aluminum is a highly recyclable material, with recycling processes that retain its properties without loss in quality. This makes it an environmentally friendly choice for flooring as it reduces waste and conserves resources. Recycled aluminum can be used to create new profiles for flooring systems, maintaining strength and durability while offering a sustainable solution.</p>

- Q: Are aluminum profiles suitable for exhibition booths?

- Yes, aluminum profiles are suitable for exhibition booths. They are lightweight, durable, and easy to assemble and disassemble, making them ideal for creating versatile and portable booth structures. Additionally, aluminum profiles offer a sleek and modern aesthetic, allowing for customization and branding opportunities.

- Q: What are the mechanical properties of aluminum profiles?

- Factors such as alloy composition, heat treatment, and manufacturing processes have an influence on the mechanical properties of aluminum profiles. These profiles are known for their excellent strength-to-weight ratio, making them both lightweight and strong. They possess good corrosion resistance, making them suitable for various applications in different environments. Furthermore, aluminum profiles are easily shaped and fabricated into desired designs due to their good formability. They also have high thermal and electrical conductivity, making them useful in applications such as heat sinks and electrical conductors. In addition, their low density contributes to their lightweight nature. In conclusion, the versatile mechanical properties of aluminum profiles make them widely used in industries including construction, transportation, and electronics.

- Q: This question asks for an enumeration of the various types of aluminum profiles that are commonly utilized in interior wall systems.

- <p>Aluminum profiles for interior wall systems come in various types, each serving a specific purpose. These include: 1. Cover Profiles, which conceal the joints between wall panels; 2. Angle Profiles, used for creating corners and edges; 3. Connecting Profiles, facilitating the attachment of panels; 4. Support Profiles, providing structural support; 5. Joint Profiles, for aligning and securing panels at their joints; 6. Decorative Profiles, adding aesthetic appeal; 7. Insulation Profiles, for thermal insulation; and 8. Sealing Profiles, to prevent air and moisture infiltration. Each type of profile is designed to meet specific architectural and functional requirements, contributing to the overall integrity and appearance of the interior wall system.</p>

- Q: What are the differences between the 6005 and 6003 aluminum profiles?Yangmingxg3

- 6003 of the magnesium content is higher than 6005, and the strengthening of magnesium to aluminum is remarkable. With the addition of 1% mg, the tensile strength increases by about 34MPa.

- Q: Can aluminum profiles be used in the manufacturing of furniture?

- Furniture production can utilize aluminum profiles, which are versatile and lightweight materials. Aluminum possesses numerous advantages for furniture manufacturing, such as durability, corrosion resistance, and a high strength-to-weight ratio. Due to these properties, it is suitable for various furniture applications, including chairs, tables, shelving units, and frames. Moreover, aluminum profiles offer easy customization, enabling the creation of distinctive and contemporary designs. By incorporating aluminum into furniture manufacturing, sustainability is promoted as it is a recyclable material. In conclusion, aluminum profiles offer flexibility and durability to designers and manufacturers, rendering them a favored option in the furniture industry.

- Q: What are the different bending machines or tools used for aluminum profiles?

- Aluminum profiles can be shaped and angled using various bending machines and tools. These tools are designed to meet specific project requirements, manipulating the profiles in different ways. 1. For smaller aluminum profiles, the Manual Tube Bender is a hand-operated bending tool. It consists of a lever and a bending shoe, allowing for manual bending of the profile. 2. When dealing with larger and thicker aluminum profiles, the Hydraulic Tube Bender is equipped with hydraulic power. This machine offers greater precision and control, making it ideal for industrial applications. 3. The CNC Tube Bending Machine is a computer-controlled machine that combines hydraulic power and computer programming. With this machine, aluminum profiles can be accurately bent, making it suitable for high-volume production and intricate designs. 4. The Roll Bending Machine is specifically designed for bending aluminum profiles into curved shapes. It uses three rolls, with the profile passing through the middle roll while the other two rolls apply pressure to achieve the desired curve. 5. To bend aluminum profiles without deforming or collapsing the inner diameter, the Mandrel Bender is used. This tool utilizes a mandrel inserted into the profile to support the inner wall during the bending process. 6. The Rotary Draw Bender is a machine that produces accurate and repeatable bends in aluminum profiles. It uses bending dies and a rotating arm, commonly used for tubes and pipes, but can also be adapted for aluminum profiles. These bending machines and tools offer various levels of precision, control, and production capacity. Manufacturers and fabricators can select the most suitable option based on their specific needs and requirements.

- Q: How do aluminum profiles perform in vibration and shock absorption applications?

- Aluminum profiles are known to excel in vibration and shock absorption applications due to their lightweight yet durable nature. They have excellent strength-to-weight ratio, allowing them to effectively dampen vibrations and absorb shocks. Additionally, aluminum profiles possess good flexibility and resilience, enabling them to withstand repeated impacts without deformation or failure. Their high thermal conductivity also aids in dissipating heat generated during vibrations. Overall, aluminum profiles are highly suitable for vibration and shock absorption applications, providing reliable performance and longevity.

- Q: The company must tender, but it needs material certification, but what do not know exactly?

- Enterprise legal person business license, China Quality Association approved, the national industrial product production permit, 9001 certificate, a copy of tax registration certificate. Surely that will be enough

Send your message to us

Aluminum F Molding Extrusion Powder Coating Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords