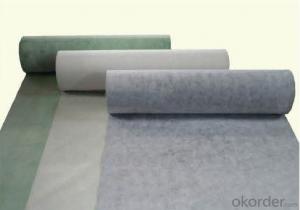

Polyvinyl Chloride (PVC) Waterproofing Membrane with UV Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

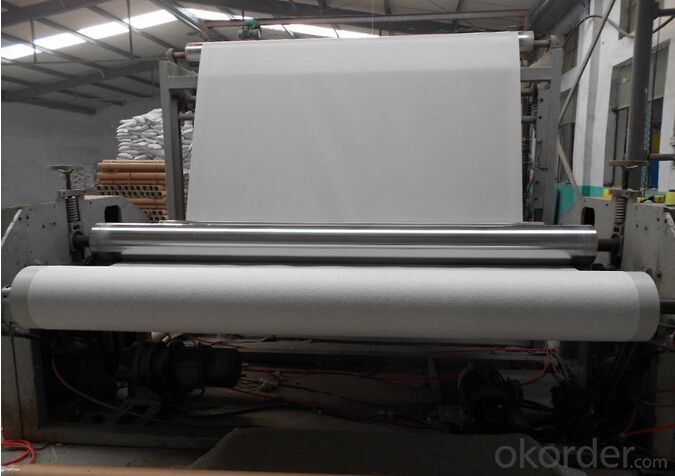

Introduction

Polyvinyl chloride (PVC) waterproofing membrane is a macromolecule waterproofing membrane with superior performance. It is mainly made of polyvinyl chloride resin added with aid agents and aging resistance elements and produced by advanced plants and techniques. It has the characteristics such as superior tensile strength, good elongation, less shrink ratio, excellent low temperature flexibility and long lifetime.

PERFORMANCE INDEX

Performance indicators of Polyvinyl chloride waterproofing membrane

S/N | Items | Units | Indicators | ||||||

H | L | P | G | GL | |||||

1 | Thickness of resin coated on the central mat ≥ | mm | - | 0.4 | |||||

2 | Tensile property | Max. tensile force ≥ | N/cm | - | 120 | 250 | - | 120 | |

Tensile strength≥ | mpa | 10.0 | - | - | 10.0 | - | |||

Elongation of max. tensile force≥ | % | - | - | 15 | - | - | |||

Elongation at break≥ | % | 200 | 150 | - | 200 | 100 | |||

3 | Dimensional stability of hot treatment ≤ | % | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | ||

4 | Low temperature bending -25°C | No crack | |||||||

5 | Water tightness 0.3kpa, 2h | Impermeable | |||||||

PRODUCT FEATURES

Long lifetime and aging resistance. Lifetime of waterproofing membrane used on the roof is 20 years and that of waterproofing membrane underground.

Superior tensile strength, excellent elongation and less dimensional variation after hot treatment.

Superior low temperature flexibility and good performance suitable for environmental temperature change

Strong resistance to root puncture to be used for the roof

Excellent non-inflammability and self-quenching performance

Mildew resistance and efficient resistance to microbe damage

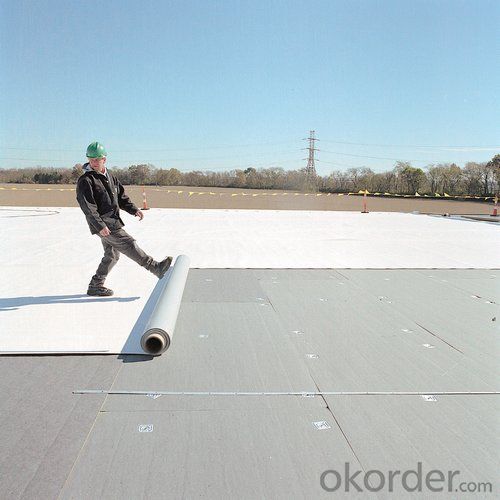

Easy installation, stable welding and friendly to environment

Strong chemical resistance and applied to special condition

Excellent modeling property and quick treatment to the corner

Convenient maintenance with low cost

RFQ

1. What is your MOQ?

--Our MOQ is 5000 m2

2. Can you provide sample?

--Yes, samples are in stock. we can offer free sample for you.

3. Do you offer OEM service?

--Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: How long does a waterproofing membrane last?

- The lifespan of a waterproofing membrane can vary depending on several factors. Generally, a well-installed and properly maintained waterproofing membrane can last between 10 to 20 years. However, this estimate can be influenced by various factors such as the quality of the membrane material, the level of exposure to environmental elements, the frequency of foot traffic or other stressors, and the overall maintenance and care provided. It is important to note that regular inspections and maintenance are crucial for prolonging the lifespan of a waterproofing membrane. Additionally, following manufacturer guidelines and recommendations can ensure optimal performance and increase the longevity of the membrane.

- Q: Can a waterproofing membrane be used on precast insulation surfaces?

- Indeed, precast insulation surfaces can make use of a waterproofing membrane. The primary purpose of this membrane is to create a safeguard against water infiltration, and it can be applied to diverse surfaces, such as precast insulation. In effect, the membrane serves to thwart water from penetrating the insulation, thereby averting potential harm and preserving its efficacy. By employing a waterproofing membrane on precast insulation surfaces, one can guarantee that the insulation stays dry and preserves its thermal properties for the long term.

- Q: Can a waterproofing membrane be used on flat roofs?

- Yes, a waterproofing membrane can be used on flat roofs. In fact, it is one of the most common and effective methods of waterproofing flat roofs. A waterproofing membrane is a thin layer of material that is applied to the surface of the roof to prevent water from penetrating through. It is typically made of a durable and flexible material, such as synthetic rubber or modified bitumen, which can withstand the elements and provide long-lasting protection. The membrane is installed in overlapping layers, creating a continuous barrier that effectively seals the roof and prevents water from leaking into the building. Additionally, waterproofing membranes can also provide insulation and energy efficiency benefits, making them a popular choice for flat roof applications.

- Q: Can a waterproofing membrane be used on tunnels with architectural features?

- Indeed, tunnels with architectural features can benefit from the application of a waterproofing membrane. Such membranes possess versatility, enabling their usage on different structures, including tunnels with architectural elements. Their primary purpose is to establish a protective barrier against water infiltration, consequently safeguarding the structure against moisture-related harm. Regardless of the tunnel's unique architectural components, such as curves, arches, or decorative embellishments, a tailored waterproofing membrane can be tailored and implemented to ensure optimal water resistance. Therefore, it is imperative to seek guidance from a proficient waterproofing specialist experienced in working with tunnels and architectural features. They will assist in determining the most suitable membrane system for the specific project prerequisites.

- Q: Can a waterproofing membrane be used in elevator pits?

- The utilization of a waterproofing membrane in elevator pits is possible. Due to their subterranean location, elevator pits are susceptible to water intrusion from sources like groundwater or moisture. A waterproofing membrane acts as a safeguarding layer that is applied to the walls and floor of the elevator pit, effectively obstructing the passage of water. This protective barrier prevents water from causing harm to vital components of the elevator system, such as electrical equipment, pumps, and hydraulic systems. Implementing a waterproofing membrane in elevator pits substantially diminishes the likelihood of water damage and corrosion, ensuring the elevator's safe and efficient operation.

- Q: Can a waterproofing membrane be used for a foundation wall?

- A foundation wall can indeed utilize a waterproofing membrane. It is highly advisable to employ such a membrane to shield the foundation against water infiltration and moisture-related harm. Typically, this membrane is applied on the outer side of the foundation wall, serving as a barrier to prevent water from penetrating. Its design entails flexibility, durability, and resistance to hydrostatic pressure, thereby ensuring long-lasting protection for the foundation. Moreover, the membrane aids in preventing water from seeping into the basement or crawl space, thereby decreasing the risk of mold, mildew, and structural problems. Ultimately, employing a waterproofing membrane for a foundation wall is an effective means of safeguarding the building's foundation, guaranteeing its integrity and longevity.

- Q: Where are waterproofing membranes commonly used?

- Waterproofing membranes are commonly used in a variety of applications to prevent water infiltration and protect structures from moisture damage. Some of the common areas where waterproofing membranes are used include: 1. Basements: Waterproofing membranes are extensively used in basements to prevent water seepage through foundation walls and floors. They create a barrier that keeps water out and helps maintain a dry and habitable space. 2. Roofs: Waterproofing membranes are widely used in roofing systems to protect buildings from rain, snow, and other elements. They are applied beneath the roofing materials and act as a barrier against water penetration, ensuring the structural integrity of the roof. 3. Bathrooms and wet areas: Waterproofing membranes are essential in bathrooms, showers, and other wet areas to prevent water from seeping into the walls and floors. They create a watertight seal that helps to avoid mold growth, water damage, and structural issues. 4. Balconies and terraces: Waterproofing membranes are commonly applied to balconies, terraces, and other outdoor areas to protect them from water damage and ensure durability. They provide a protective layer that keeps water from penetrating the surface and causing deterioration. 5. Swimming pools: Waterproofing membranes are extensively used in the construction of swimming pools to prevent water leakage. They are applied to the pool shell and provide a watertight seal, ensuring that the pool remains structurally sound and water-tight. 6. Tunnels and underground structures: Waterproofing membranes are used in tunnels and underground structures to protect them from groundwater seepage. They form a waterproof barrier that prevents water from infiltrating and causing damage to the structure. 7. Planter boxes and green roofs: Waterproofing membranes are commonly used in planter boxes and green roofs to prevent water from seeping into the building structure. They create a barrier that retains moisture within the planter or green roof while preventing water infiltration into the building. Overall, waterproofing membranes play a crucial role in various construction projects, ensuring the protection and longevity of structures by preventing water damage and moisture-related issues.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Yes, a waterproofing membrane can be used for plant rooms or mechanical spaces. Plant rooms and mechanical spaces are areas where equipment, machinery, or systems are installed, and they often contain pipes, tanks, or other components that require protection from water damage. A waterproofing membrane is a durable, flexible, and watertight barrier that can be applied to surfaces such as walls, floors, or ceilings to prevent water infiltration. By using a waterproofing membrane in plant rooms or mechanical spaces, you can ensure the longevity and functionality of the equipment and systems by protecting them from water leaks or moisture damage. Additionally, a waterproofing membrane can also provide a vapor barrier, preventing the buildup of condensation or humidity, which can be detrimental to sensitive equipment.

- Q: Can a waterproofing membrane be used for a plaza deck waterproofing?

- Yes, a waterproofing membrane can be used for plaza deck waterproofing. Plaza decks are typically exposed to the elements, including rain and snow, and require a waterproofing system to prevent water infiltration and potential damage to the structure below. Waterproofing membranes are designed specifically for this purpose, offering a barrier against water and protecting the deck from moisture-related issues such as leaks, deterioration, and mold growth. These membranes are typically made from materials such as bitumen, PVC, or EPDM, and are applied in multiple layers to ensure a durable and watertight seal. By using a waterproofing membrane, plaza decks can effectively maintain their structural integrity and longevity.

- Q: Can a waterproofing membrane be used on precast cement board surfaces?

- Yes, a waterproofing membrane can be used on precast cement board surfaces. The membrane acts as a protective barrier against water infiltration and helps to prevent damage to the cement board.

Send your message to us

Polyvinyl Chloride (PVC) Waterproofing Membrane with UV Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords