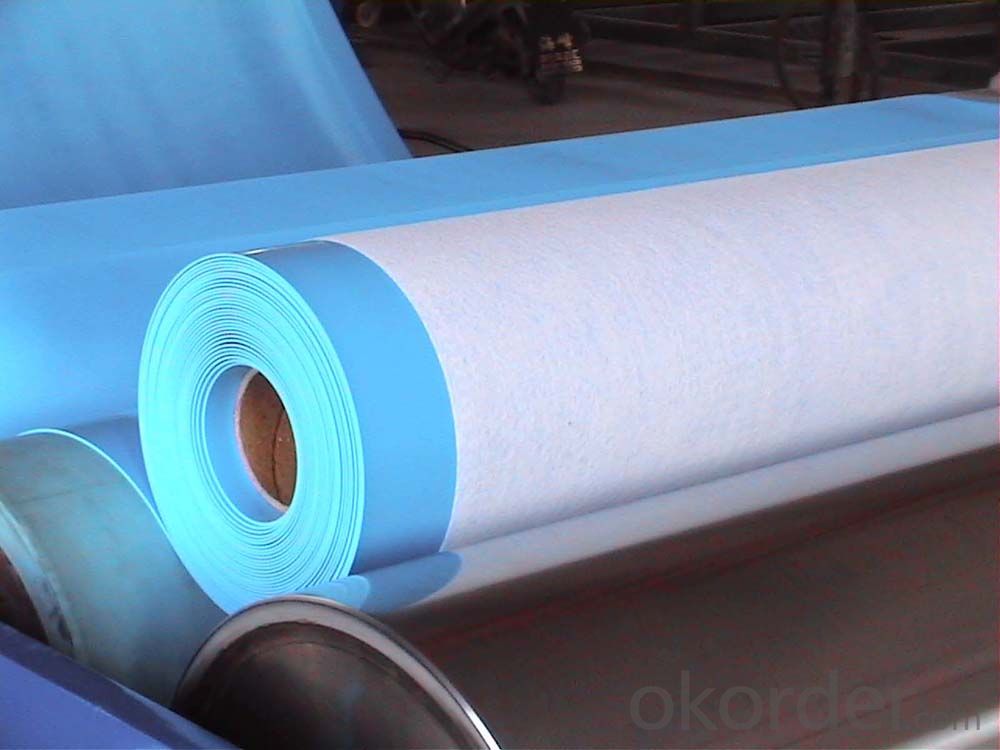

Polyvinyl Chloride (PVC) waterproofing membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of Polyvinyl Chloride (PVC) waterproofing membrane:

Polyvinyl Chloride (PVC) waterproofing membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer,filler, antioxygen, ultraviolet absorber and other auxiliaries. DHK-8100 adopts automatic mixing of raw material, double-screw extruder and delicate three-roller calender equipment in the PVC membrane production. DHKchem PVC waterproof membrane features dimensional stability and high tensile strength, being a best choice for many civil and industrial project.

2.Physical data of Polyvinyl Chloride (PVC) waterproofing membrane:

No | Item | I | II | |

1 | Tensile strength/ Mpa | 8.0 | 12.0 | |

2 | Fracture elongation / % ≥ | 200 | 250 | |

3 | Heating flexibility / % ≤ | 3.0 | 2.0 | |

4 | Cold bending | -20°C No leaking | -25°C No leaking | |

5 | Water impermeability | Water impermeable | ||

6 | Binding property with cutting (N/mm) | 3.0/ breaking membrane | ||

7 | Hot air ageing | Appearance | No craze, no bubble, no cohering, hole | |

Tension strength % | ±25 | ±20 | ||

Fracture elongation changing rate | ||||

Cold bending % | -15°C No leaking | -20°C No leaking | ||

8 | Chemistry corrosion resistance | Tension strength % | ±25 | ±20 |

Fracture elongation changing rate | ||||

Cold bending % | -15°C No leaking | -20°C No leaking | ||

9 | Phytotrons accelerating ageing | Tension strength % | ±25 | ±20 |

Fracture elongation changing rate | ||||

Cold bending % | -15°C No leaking | -20°C No leaking | ||

10 | Note: no considering phytotrons accelerating ageing. | |||

3.Chatacteristics of Polyvinyl Chloride (PVC) waterproofing membrane:

Excellent performance in aging resistance, service life of 20 years for exposed use, and 50 years for non-exposed application.

Easy installation and hot-air welding seam, environmental friendly.

High tension, perfect elongation, perfect heating resistance.

Excellent jointing, it can be fused with base as a whole after heating jointing.

High permeability, chilling material and moisture can be expelled easily.

High UV resistance , corrosion resistance and erosion resistance.

High cold flexibility (-20°C).

Surface can reflect UV. The temperature on the surface is low due to little absorbing heat.

4.Application of Polyvinyl Chloride (PVC) waterproofing membrane:

Colorful polymer PVC waterproof membrane can variously be used on the roof of building, underground building, tunnel, dam, pool, sewage treatment works, and garbage disposal facilities. It also can be suitable to any requirement of all kinds of technological practice & different grade of roof waterproof and underground constructions waterproof.

- Q: Can waterproofing membranes be painted over?

- Yes, waterproofing membranes can be painted over. However, it is important to ensure that the paint used is compatible with the membrane material. It is recommended to consult the manufacturer's guidelines or seek professional advice to ensure proper adhesion and longevity of the paint. Additionally, the surface should be clean and dry before applying the paint to ensure optimal results. Overall, painting over a waterproofing membrane can help enhance its appearance and provide additional protection against UV rays and other environmental factors.

- Q: What is the meaning of the node and the additional layer in the construction of the membrane waterproofing layer?

- Waterproof membrane construction, the node is relative to the large area of the plane in terms of. Node parts are: yin and yang angle, the root of the pipeline, the rain shed, all kinds of flooding, expansion joints, deformation joints, construction joints, through the wall and other areas need to focus on processing.

- Q: Are there any specific requirements for installing a waterproofing membrane?

- Yes, there are specific requirements for installing a waterproofing membrane. These requirements may vary depending on the type of membrane being used and the specific application. However, some general requirements include: 1. Surface Preparation: The surface where the membrane will be installed must be clean, dry, and free from any dust, debris, or contaminants. Any cracks or defects in the surface should be repaired prior to installation. 2. Adhesive or Bonding Agent: Depending on the type of membrane, an adhesive or bonding agent may be required to ensure proper adhesion to the substrate. This adhesive should be compatible with both the membrane and the substrate. 3. Primer: In some cases, a primer may be necessary to enhance the adhesion between the substrate and the membrane. The type of primer required will depend on the specific membrane and substrate being used. 4. Seam and Joint Preparation: Properly preparing seams and joints is crucial to ensure a watertight installation. This may involve using a specific sealant or tape to reinforce the seams and prevent water penetration. 5. Installation Techniques: The membrane should be installed according to the manufacturer's instructions and industry best practices. This may include using a specific method such as torching, hot air welding, or cold adhesive application. 6. Overlaps and Transitions: Properly overlapping the membrane sheets and ensuring smooth transitions between different areas is essential for a successful installation. This will help prevent water from seeping through gaps or weak points in the membrane. 7. Quality Control: Regular inspections and quality control measures should be implemented throughout the installation process to ensure that the membrane is being installed correctly and meets the required standards. It is important to consult the manufacturer's guidelines and specifications for the specific waterproofing membrane being used, as different membranes may have unique installation requirements. Additionally, local building codes and regulations should also be considered to ensure compliance and to meet any specific requirements in your area.

- Q: Can a waterproofing membrane be used for tunnels and subway stations?

- Yes, a waterproofing membrane can be used for tunnels and subway stations. The membrane acts as a barrier against water infiltration and helps protect the structure from water damage. It is commonly used in underground construction projects to ensure the longevity and safety of tunnels and subway stations.

- Q: Does a waterproofing membrane provide any UV resistance?

- Yes, a waterproofing membrane can provide some degree of UV resistance. Many waterproofing membranes are designed to be used in outdoor applications where they will be exposed to sunlight. These membranes often incorporate UV stabilizers or additives that help to protect the membrane from the damaging effects of UV rays. However, it is important to note that the level of UV resistance provided by a waterproofing membrane can vary depending on the specific product and manufacturer. It is always recommended to consult the manufacturer's specifications and guidelines to determine the UV resistance capabilities of a particular waterproofing membrane.

- Q: What is the difference between polymer waterproofing membrane and cross film waterproofing membrane?

- he strong cross-over film of the product is a high-strength HDPE film formed by the cross-laminating process. The film and the like have the same vertical and transverse elongation ratio. The coil does not send deformation, more beautiful and waterproof reliable.

- Q: Are waterproofing membranes resistant to frost damage?

- Waterproofing membranes, in general, exhibit resistance towards frost damage. These membranes are specifically crafted to endure diverse weather conditions, which include freezing temperatures. They typically comprise modified bitumen, PVC, EPDM, or TPO, materials renowned for their exceptional frost and environmental resistance. These materials are engineered to maintain their flexibility and elasticity, even in low temperatures, ensuring the preservation of the waterproofing membrane's effectiveness in preventing water infiltration. Furthermore, meticulous installation methods and regular maintenance can augment the waterproofing membranes' resistance to frost damage.

- Q: Does a waterproofing membrane require any specific preparation of the substrate before installation?

- Yes, a waterproofing membrane typically requires specific preparation of the substrate before installation. The substrate needs to be clean, dry, and free from any debris, oils, or contaminants that may hinder adhesion. It may also require smoothing or leveling of the surface to ensure proper application and effectiveness of the membrane.

- Q: Are there any specific building code requirements for waterproofing membranes?

- Yes, there are specific building code requirements for waterproofing membranes. These requirements vary depending on the local building codes and regulations in each jurisdiction. However, in general, building codes typically outline the necessary standards for materials, installation methods, and performance criteria of waterproofing membranes to ensure effective protection against water infiltration in structures. It is important to consult and adhere to these codes to ensure compliance and maintain the durability and integrity of the building.

- Q: What is the best waterproofing membrane for my project?

- The best waterproofing membrane for your project depends on several factors such as the type of project, location, budget, and specific requirements. It is recommended to consult with a professional waterproofing expert who can assess your project's needs and recommend the most suitable membrane based on these factors.

Send your message to us

Polyvinyl Chloride (PVC) waterproofing membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords