Polyvinyl Chloride (PVC) New Polymer Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction of PVC Waterproofing Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

2. Features of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

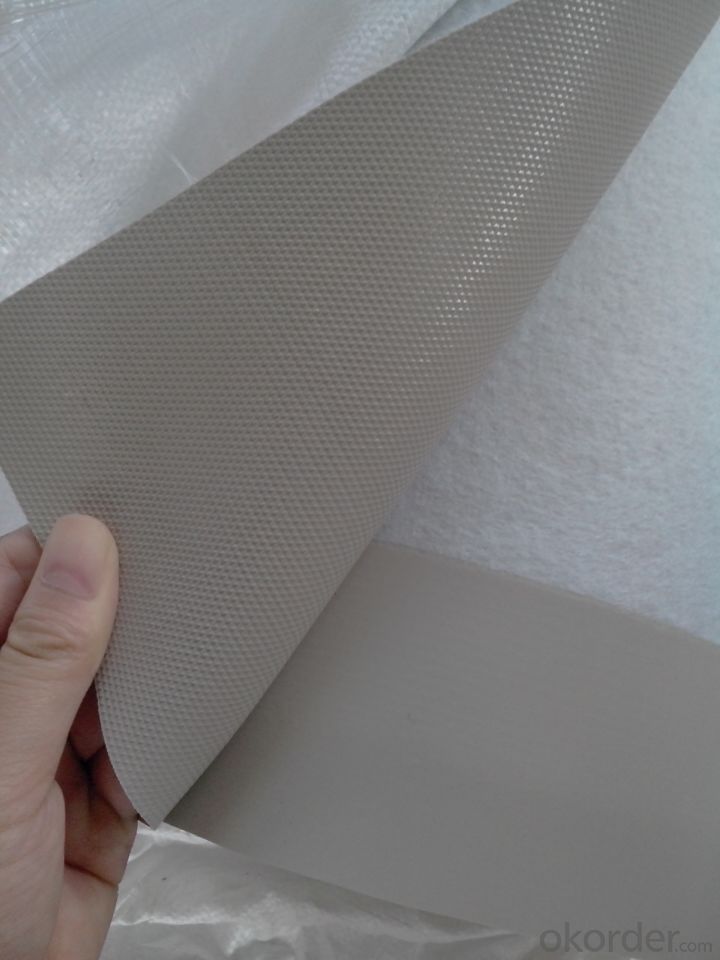

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

3. Specification of PVC Waterproofing Membrane

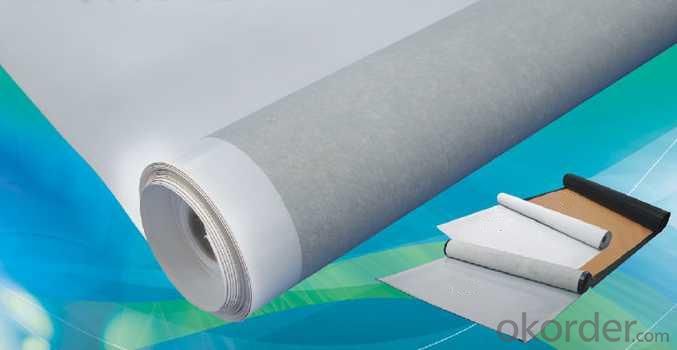

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

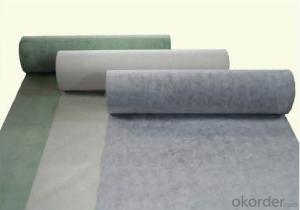

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

4. Types of PVC Waterproofing Membrane

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric.

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

5. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for temporary structures or tents?

- Yes, a waterproofing membrane can be used for temporary structures or tents. Waterproofing membranes are designed to provide a protective barrier against water, preventing it from penetrating the surface and causing damage. This makes them an ideal choice for temporary structures or tents, as they can effectively keep the interior dry during rain or other wet conditions. Additionally, waterproofing membranes are often lightweight and flexible, making them easy to install and remove, which is especially beneficial for temporary structures or tents that may need to be relocated or dismantled.

- Q: Can a waterproofing membrane be used for underground electrical vaults?

- Yes, a waterproofing membrane can be used for underground electrical vaults. Underground electrical vaults are susceptible to water infiltration, which can cause damage to the electrical equipment and compromise their functionality. Waterproofing membranes are designed to provide a barrier against water and moisture, effectively preventing water from entering the vault. These membranes are specifically engineered to be highly durable and resistant to water penetration, ensuring long-term protection for the electrical equipment within the vault. Moreover, waterproofing membranes can also help in preventing corrosion and extending the lifespan of the electrical vaults. Therefore, using a waterproofing membrane is highly recommended for underground electrical vaults to maintain the integrity and functionality of the electrical equipment.

- Q: Is a waterproofing membrane resistant to gasoline or other petroleum-based substances?

- Yes, a waterproofing membrane is typically resistant to gasoline and other petroleum-based substances. Most waterproofing membranes are made from materials such as polyurethane or PVC, which are known for their resistance to chemicals and petroleum products. This resistance ensures that the membrane remains intact and effective in preventing water infiltration even when exposed to gasoline or other petroleum-based substances. However, it is important to note that the specific resistance level may vary depending on the type and quality of the waterproofing membrane used. It is advisable to consult with a professional or check the product specifications to ensure that the chosen membrane is suitable for the intended application involving gasoline or petroleum-based substances.

- Q: Can waterproofing membranes be used on metal roofs?

- Yes, waterproofing membranes can be used on metal roofs. Waterproofing membranes are a popular choice for protecting and sealing roofs, including metal roofs. These membranes are designed to provide a barrier against water penetration, protecting the roof structure and preventing leaks. They can be applied directly to the metal roof surface, creating a watertight seal that is resistant to moisture, UV rays, and other environmental factors. Waterproofing membranes can effectively extend the lifespan of metal roofs by preventing rust and corrosion, while also improving energy efficiency by reducing heat transfer. Therefore, using waterproofing membranes on metal roofs is a viable and effective solution for ensuring durability and longevity.

- Q: Does a waterproofing membrane require any curing time?

- Indeed, a curing time is typically necessary for a waterproofing membrane to fully bond and establish a robust, impermeable barrier. The duration of this curing period can differ based on the type of membrane employed and the instructions provided by the manufacturer. While the membrane is undergoing the curing process, precautions should be taken to shield it from foot traffic, water exposure, and any other potential sources of harm. Adhering to the recommended curing time is crucial in guaranteeing the membrane's effectiveness and durability.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels?

- Yes, a waterproofing membrane can be used in areas with high groundwater levels. Waterproofing membranes are designed to prevent the penetration of water and can be effective in areas where groundwater levels are high. However, it is important to ensure that the membrane is properly installed and meets the specific requirements of the site conditions to ensure optimal performance.

- Q: How much does a waterproofing membrane cost?

- The cost of a waterproofing membrane can vary depending on several factors. The type of membrane, the size of the area to be waterproofed, and the complexity of the installation can all affect the price. On average, the cost of a waterproofing membrane can range from $1 to $5 per square foot. However, this is just a rough estimate and the actual cost can be higher or lower based on the aforementioned factors. For example, a basic sheet membrane made of PVC or EPDM might be on the lower end of the price range, while a liquid-applied membrane or a more advanced system like a bentonite clay membrane can be on the higher end. Additionally, the size of the area to be waterproofed will impact the cost. Larger areas will require more materials, labor, and time, which can increase the overall price. Complexity of the installation is another factor to consider. If the area is hard to access or requires extensive preparation work, such as removing existing materials or repairing cracks, the cost may be higher. It is recommended to consult with a professional waterproofing contractor who can assess your specific needs, provide an accurate estimate, and recommend the most suitable waterproofing membrane for your project.

- Q: What is the difference between a self-adhesive and torch-applied waterproofing membrane?

- The main difference between a self-adhesive and torch-applied waterproofing membrane lies in the method used to adhere the membrane to the substrate. Self-adhesive waterproofing membranes have a pre-applied adhesive layer which allows for easy installation by simply removing the backing and sticking it onto the surface. On the other hand, torch-applied waterproofing membranes require the use of a propane torch to heat the underside of the membrane, melting the bitumen layer and allowing it to bond with the substrate. While both methods provide effective waterproofing, the choice between self-adhesive and torch-applied membranes depends on factors such as surface type, installation conditions, and personal preference.

- Q: Can a waterproofing membrane be used for planter boxes and green roofs?

- Yes, a waterproofing membrane can be used for planter boxes and green roofs. The membrane prevents water leakage and provides a protective barrier for the underlying structure, ensuring that the planter boxes and green roofs remain waterproof and durable.

- Q: Can a waterproofing membrane be used for roof gardens?

- Yes, a waterproofing membrane can be used for roof gardens. It is a common practice to use waterproofing membranes as a protective layer beneath the soil and plants in roof garden installations. These membranes help prevent water leakage into the building below and ensure the longevity of the roof garden system.

Send your message to us

Polyvinyl Chloride (PVC) New Polymer Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords