Polyester Short Fiber Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Short Fiber Needle Punched Nonwoven Geotextile

1. Product Description:

Needle punched nonwoven Geotextiles are made of polyester or polypropylene in random directions and punched together by needles.

Geotextiles has good impermeability and resistance to deformation, which allows geotextiles be widely applied in civil projects for separation,filtration,reinforcement, protection and drainage.

Geotextiles can be used as:

* Filtration or separation layers in civil engineering projects of roads and railway construction;

* Protect layer for geomembranes in landfill construction;

* Coastal defence applications

* Landscaping projects to maintain soil and protect land surfaces and structures from weeds and root growth.

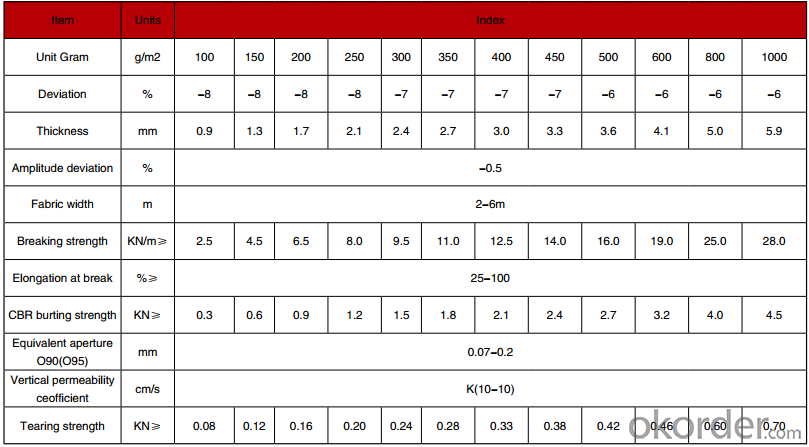

2. Data sheet:

3. Main Features

2) High temperature resistance to up to 230℃ maintaining structure stability and original physical properties;

3) High flat drainage and vertical permeability;

4) High creep resistance;

5) Resistance of erosion of chemicals in soil as well as the corrosion of gasoline and diesel etc;

6) High elongation under certain stress, thus able to adapt to uneven and irregular bases;

4. Packaging & Shipping:

white fabric bag or black PE bag outside or as required.

7 days after received deposite

5. Applications of NON-Woven Geotextile :

Non woven Geotextiles can be widely used in railways, highways, sports halls, ,garbage dump ,dams, hydraulic construction, tunnels, coastal beaches, land reclamation, environmental protection and other projects.

Notes : The specification is based on mass area ratio.

When the actual specification is between adjacent specifications in this table, it is necessary to calculate the corresponding evaluation indicators in accordance with the interpolation method;

If the range in table is exceeded, it is necessary to determine the evaluation indicators through consultation by the supply and demand sides.

6.Pictures

7. FAQ:

Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000,but it is negotiable.

Q3:What is your payment terms?

A: T/T,Western Union,L/C.

Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q: What are the specifications for geotextiles used in geosynthetic tubes?

- The specifications for geotextiles used in geosynthetic tubes may vary depending on the specific application and project requirements. However, some common specifications include factors such as the tensile strength, permeability, UV resistance, puncture resistance, and filtration properties. It is important to consider the specific project conditions and engineering design to determine the suitable specifications for geotextiles used in geosynthetic tubes.

- Q: Artificial lake geotextile practices

- Library and slope with a composite geomembrane all laying, I specialize in the production and construction of geotextile materials

- Q: Construction scheme of geotextile water filter

- Second, the design: program one: in strict accordance with the requirements of the national standard construction, 5-year warranty 1, in the smooth level of leveling the overall construction brushing JS waterproof latex or polyurethane waterproof coating, the thickness of the national standard 1 standard; Weak parts to do additional layer to strengthen; 2, do 20 ~ 30mm thick waterproof mortar protective layer, divided into two construction, layer waterproof layer of pulp interface; require nano-silicon waterproofing agent and expansion agent compound use. 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice ibid, the wall to do high 1m. Option 2: with reference to national standard requirements simple practice, the warranty period of 1 year 1, the overall construction of coated asbestos asphalt waterproof coating or waterproof cold primer, the thickness of the standard by the national standard 2; special weak parts to do additional layer to strengthen; Outside the protection, requiring the use of sticky or sticky sticky construction; 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice reference program one, the wall to do high 1m.

- Q: Can geotextiles be used in golf course construction?

- Yes, geotextiles can be used in golf course construction. Geotextiles provide several benefits such as soil stabilization, erosion control, and drainage management, which are important for maintaining the integrity and performance of golf courses.

- Q: What are the different geotextile tensile strength test methods?

- There are several different geotextile tensile strength test methods, including the grab test, strip test, wide-width strip test, and trapezoid tear test. Each method has its own advantages and is used to evaluate the tensile strength and performance of geotextiles in different applications.

- Q: How do geotextiles contribute to pavement design?

- Geotextiles play a crucial role in pavement design by providing various benefits. They help in enhancing the structural integrity of the pavement by distributing loads more uniformly, minimizing stress and preventing cracking. Geotextiles also act as a separator, preventing the mixing of subgrade soil with the overlying pavement layers. Additionally, they aid in filtration by allowing water to pass through and drain efficiently, preventing water buildup and potential damage. Overall, geotextiles contribute to the longevity and durability of pavements by improving their performance and reducing maintenance needs.

- Q: What are the factors to consider when selecting geotextiles for coastal protection projects?

- When selecting geotextiles for coastal protection projects, several factors need to be considered. These include the strength and durability of the geotextile, its resistance to UV radiation and chemicals, its ability to filter and drain water, its compatibility with the existing soil and vegetation, its installation and maintenance requirements, and its cost-effectiveness. Additionally, the specific environmental conditions and project goals should also be taken into account.

- Q: Filter geotextile performance ~ main function ~

- Filter geotextile performance ~ main function ~

- Q: Permeable geotextile price how much

- 2 to 4 yuan range

- Q: Geotextile construction inspection batch ye do?

- Plastic woven category: the same formula, the same specifications of 100,000 square meters of products for a group; less than 100,000 square meters, the actual number of a batch. Non-woven geotextiles: the same frequency of production of the same specifications for a number of products; batch volume can be accumulated 100 volumes for a group, but the week is still less than 100 volumes of output, then with a group of output. Plastic woven cloth: batch as a unit, each batch of products randomly take 3 volumes as a sample geotextile categories: each batch of products randomly selected 2% to 3%, but not less than 2 volumes. Sample requirements: the whole width, length 3m or more, the sample can be rolled up, but can not be folded.

Send your message to us

Polyester Short Fiber Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords