Hps6 Non Woven Geotextile with Short Fiber Needle Punched

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non Woven Geotextile with Short Fiber Needle Punched, Find Details about Non Woven Geotextile with Short Fiber Needle Punched and Make an Inquiry for Geotextile at OKorder.com.

Geotextile Specifications:

Geotextile fabrics

Material:polyester fibric

Width:2-6m

Colour:white or black

Use:road ,highway,filter

Weight:100-1000g/m2

Tensile strength:2.5KN/m-25KN/m

Break elogation:25-100%

Gextextile Description:

--Our geotextile can be made of polypropylene (PP) or polyester (PET) .

-- The weight is available from 100g/m2 to 1500g/m2 and the width from 1m to 8m,

-- Two kinds of processing technical to select: needle punched and thermally bonded, long fiber or short fiber.

-- All kinds of colors are available.

It is widely known as earthwork material and industry fabric, used in the areas of railway, highway, water conservancy, dam, tunnel, subway, environment protection and so on.

-- We can supply different specifications as customers’ request.

Geotextile Specification:

Material: polypropylene (PP) thermally bounded

Weight: 100g/m2-1200g/m2

Width: 1-8m

Length: As customers’ demand (usually is 100m)

Package: PE film and woven cloth

Delivery time: With in 3weeks after received the advance payment

Payment terms: T/T 30% in advance+T/T 70% against the copies of original documents or L/C

PS. Also we can produce the product as customer’s demand.

Application of Geotextile:

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2. Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soilstone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4. Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

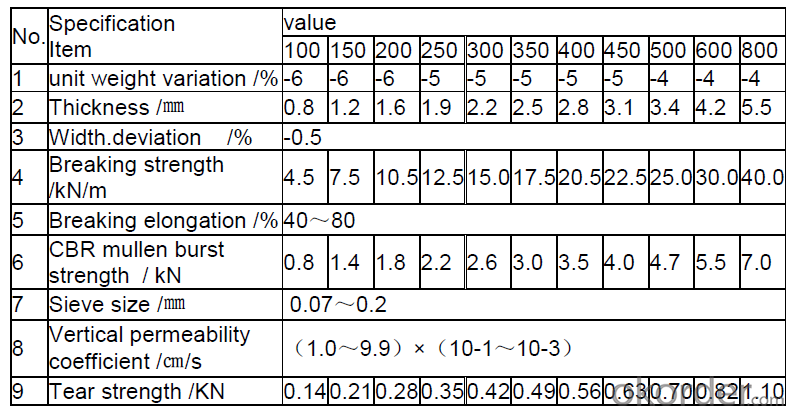

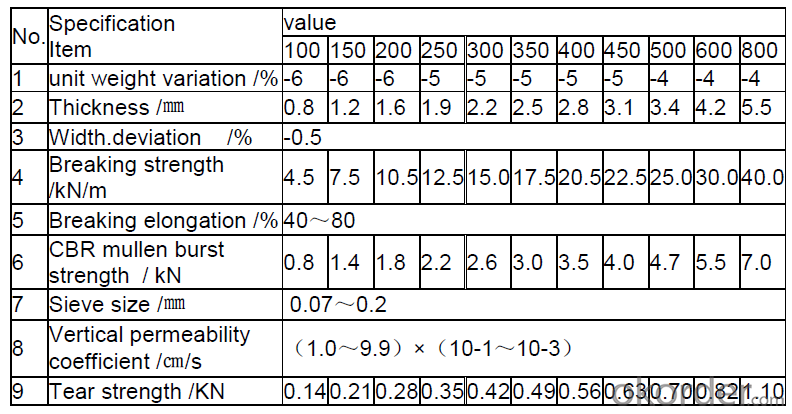

Technical specification of short fiber needle punched non-woven geotextiles:

According to GB/T17638-1998 Standard

Geotextile Specification

Geotextile Show:

Geotextile Show:

RFQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

If you want to find more details about the non-woven geotextile, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Fish tank white filter cotton toxic, is not geotextile, or non-woven Yeah

- No toxic, geotextile and non-woven raw materials are polyester, chemical name PET, its normal situation is not toxic, if the heating temperature reaches 117 degrees, will precipitate some chemical substances, when the fish may have an impact. But your water temperature will not reach 117 degrees, unless you want to drink fish soup, so there is no problem

- Q: Can geotextiles be used in agriculture?

- Yes, geotextiles can be used in agriculture. They are commonly used to control erosion, improve soil structure, and provide weed control. They can also help in drainage and filtration systems, as well as protect plants from harsh weather conditions.

- Q: What are the cost considerations for geotextiles?

- The cost considerations for geotextiles depend on factors such as the type and quality of the geotextile, the required strength and durability, the size of the project, and the installation method. Generally, higher-quality geotextiles with better performance characteristics tend to be more expensive. Additionally, the quantity of geotextile required for a project and the labor costs associated with installation can significantly impact the overall cost. Therefore, it is essential to carefully analyze the specific needs of the project and compare prices from different suppliers to make an informed decision.

- Q: Can geotextiles be used in drainage applications?

- Yes, geotextiles can be used in drainage applications. They are commonly used to enhance the performance of drainage systems by providing filtration, separation, and reinforcement. Geotextiles can help prevent soil erosion, control sediment, and improve water flow, making them suitable for various drainage applications such as retaining walls, roadways, and agricultural fields.

- Q: What are the design considerations for geotextile-reinforced soil walls?

- Some of the key design considerations for geotextile-reinforced soil walls include the selection and placement of appropriate geotextile materials, determining the required strength and stability of the wall, considering the potential for water drainage and filtration, accounting for settlement and creep behavior, evaluating the impact of external loads and surcharges, and ensuring proper construction techniques are followed. Additionally, considerations for long-term durability, environmental factors, and aesthetic aspects may also be taken into account depending on the specific project requirements.

- Q: Can geotextiles be used in geosynthetic encased columns?

- Yes, geotextiles can be used in geosynthetic encased columns. Geotextiles are commonly employed in geosynthetic encased columns to provide filtration, separation, and reinforcement functions. They help prevent soil erosion, improve drainage, and enhance the stability and performance of the geosynthetic encased columns.

- Q: Can geotextiles be used in coastal protection projects?

- Yes, geotextiles can be used in coastal protection projects. Geotextiles are permeable fabrics that can effectively control erosion and stabilize soil in coastal areas. They are commonly used to prevent sediment loss, promote vegetation growth, and provide shoreline protection against wave action. Geotextiles can be installed as a barrier or a filter to retain sediment and prevent erosion, making them a valuable tool in coastal protection projects.

- Q: Where is the sale of geotextiles in Tibet?

- Tibet geotextile, a variety of specifications, & lt; Ji Han irrigation pit thieves ghosts and bursonoids p & gt;

- Q: Health geotextile how much money ah?

- Health geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. The price according to the weight and standard to set, weight (80-1500g / ㎡), the quality standard is a requirement, divided into non-standard, whitening A, Sinochem, the general national standard, Paul national standard, Wait. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: How do geotextiles help in reducing the risk of slope failures?

- Geotextiles help in reducing the risk of slope failures by providing reinforcement and stabilization to unstable slopes. These materials are placed within the slope to increase its strength and prevent erosion. Geotextiles also help in promoting water drainage and filtration, which reduces the build-up of hydrostatic pressure within the slope. Overall, geotextiles enhance the stability of slopes and mitigate the potential for landslides or slope failures.

Send your message to us

Hps6 Non Woven Geotextile with Short Fiber Needle Punched

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords