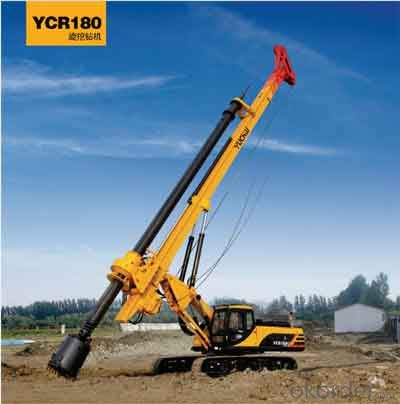

yuchai YC180R Rotary drilling rig

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

yuchai YC180R Rotary drilling rig

Technical Specifications

Item | Parameters | ||

Chassis | Engine Model |

| CUMMINS 6C8.3 |

Rated Power/Speed | kW/rpm | 194/1800 | |

Outer Width of Crawler | mm | 4100 | |

Width of Crawler Plate | mm | 800 | |

Hauling Force | kN | 390 | |

Power Head | Maximum Torque | kN·m | 180 |

Speed | r/min | 7-25 | |

Maximum Pressure | kN | 120 | |

Maximum Pulling Force | kN | 180 | |

Pressurized Cylinder Stroke | mm | 3600 | |

Hoist | Main Hoist |

|

|

First Layer of Lifting Force | kN | 180 | |

Maximum Lifting Speed | m/min | 46 | |

Diameter of Wirerope | mm | Φ26 | |

Auxiliary Hoist |

|

| |

First Layer of Lifting Force | kN | 50 | |

Maximum Lifting Speed | m/min | 70 | |

Diameter of Wirerope | mm | Φ16 | |

Mast | Rake Angle | ° | 5 |

Left/Right Tilt Angle | ° | ±4 | |

Hydraulic Pump | Maximum Pressure | Mpa | 35 |

Hole Depth Hole Diameter | Maximum Drilling | mm | 1800 |

Maximum Drilling Depth | m | 55(60) | |

Drill Pipe | Drilling Pipe | mm | Φ406 |

Working Weight | t | 62 | |

Keywords:rotary drilling dig,yuchai rotary drilling dig,weichai rotary drilling rig,weichai,chinese rotary drilling rig

Yuchai Group, founded in 1951, is a set of engine industry chain and petrochemical industry chain as a whole, the implementation of related diversified industries operate large modern enterprise groups.Yuchai Group is China's leading engines, excavators, mining machinery, piling machinery, special purpose vehicle development, design, manufacturing, sales enterprise groups.now it possesses over 30 wholly-owned, share-holding and joint stock subsidiaries and a workforce of more than 23,000, with total assets of 37 billion RMB. Reputed as the Capital of Green Power in China,

Yuchai International Imp.& Exp.(Beijing) Coompany was established in accordance with Yuchai Group, an international strategic plan sales and service company, is the only window Yuchai Group International market.

- Q: Advantages and disadvantages of pile driving methods

- Here are some of the advantages and disadvantages of the above methods:Hammer method:The method is simple in construction, small in investment and convenient in construction, and has been widely used before.But there is a cut that doesn't go around. It's too noisy and doesn't work in hard soil or soft soil. It's being phased out.Static pile:Use the static pressure to press the pile into the ground, no vibration and no noise during construction. Applicable to weak soil and adjacent to the construction of structures that are afraid of vibration.But when there is a sandwich of medium thick sand with thickness greater than 2m, it is not suitable to use the static pressed pile. And there is soil squeezing effect.Vibration method:The vibration hammer is lifted to the top of the pile, pile head is connected with the vibration box pile cap or hydraulic pile clamping device for clamping, the exciting force generated by the vibration hammer pile to soil vibration, friction force between soil particles is greatly reduced, the pile under the action of self weight and mechanical force into the soil.The vibrating pile driving equipment has the advantages of simple structure, convenient operation and high efficiency. Suitable for heavy steel sheet pile, steel pipe pile and the length within the 15m slender reinforced concrete precast pile in the sand in the highest efficiency, poor little clay.

- Q: 2. Are they parallel? 3. There is a E3 in the civilian machine was high, but as the server CPU, should be at the bottom of the right?

- A pile driver is an improvement in bulldozers. No leap, but improved performance.

- Q: How to select the configuration of the pile driver, which parts are the key concerns?

- (5) diesel hammer pile machine, hoist hammer, hanging pile must use the winch ratchet insurance. Start piling hammer should be opened before the mechanical lock, the hammer claw retracts, starting out before starting the hook, prevent the hammer hanging from the pile top pile accident.(6) the diesel hammer hammer machine must adjust the amount of fuel supplied to control the height of the drop hammer, and must stop hammering when the second piston ring of the upper piston is seen.(7) diesel hammer pile machine, the end of the piling operation, the cylinder should be placed on the piston seat. The application of timber pile hammer pad or pin lock.(8) when the pile is driven by vibration, no one is allowed to stay in the lower part of the frame. When pulling out the vibration, it should be vertical upward and pull out at the same time.(9) the construction site of the static pile driver shall be flat and compacted, with a slope of no more than 3%, without any water accumulation, and no underground burial shall be confirmed.(10) power cable static pile pressing machine must overhead, electric box and motor ground zero protection line electric shock protector is firm and reliable, sensitive and effective action, not in high voltage wires under the pressure of pile, pile machine must be mobile and high-pressure line safety distance is not less than 6m.

- Q: Principles of piling

- Because of the buildings on the ground if you want to build on the ground, the ground will bear great pressure, we must ensure that the ground has enough resistance to stress strength, it is often difficult to do, so we must reinforce or improve the ground under way on the ground to bear, so I think in the pile foundation, make the most of the weight of buildings to the position below ground deep through the pile foundation, because this position is much larger than the ground bearing capacity.As to how deep the pile should be, it depends on the distribution of the ground beneath the ground (technically called the geological structure layer). If it is enough to withstand the pressure of the building, the pile hits here, and if not, it must continue to deepen.

- Q: What kind of industry can use a pile driver?

- Pile driver: economic development, led to the rapid development of the industry, especially in recent years, urban and rural areas and highways, railways, power stations and other construction to accelerate the development of pile machinery. Such as our factory production of this kind of pile machinery, more subdivision, more widely used.?Piling machine basically can be divided into hydraulic piling machine, foundation piling machine, piling machine, photovoltaic power plant hammer piling machine, hammer piling machine and four kinds of diesel hammer piling machine. Each kind of work principle is not the same.

- Q: What is the working principle of a vibratory pile driver?

- The vibration method is more efficient than other methods. It is mainly suitable for steel sheet piles, steel pipe piles and long and thin concrete precast piles within 8m long. This pile sinking method is most suitable for sand operations, and the effect is poor in clay, and more power models must be selected.

- Q: PV pile driver

- Shandong Tengzhou production of this idiot manufacturers have a few, can come to Shandong to look strong, has many years of construction experience in complex terrain. Can prevent landslides and broken stones.

- Q: Do you have a teacher with you?. I am 32 years old this year. I really want to learn this kind of machine

- This kind of machine has little, and is not very flexible, now popular is this kind of flexible operation, power enough, 360 degree rotation of small rotary drilling rig

- Q: Such as the title... Phenomenon: quiet with a sound to length, rises again, continuous... Better knowledge about this point for more,...

- This is divided into two kinds of hammer, one is the reverse pole type, one is the cylinder type, the inverted rod is not blocked, the cylinder has block, all burn diesel oil, and the cylinder is good. Ha-ha

- Q: Is there an operation certificate for percussive drill driver?

- The following is the introduction of can refer to the utility model relates to an automatic drill piling machine, the piling machine has a movable chassis, the chassis of the upper lateral order device PLC electric control box, automatic operation mechanism, hoisting part and a steering pulley and a main frame; PLC electric control box is provided with a computer program controller.

Send your message to us

yuchai YC180R Rotary drilling rig

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords