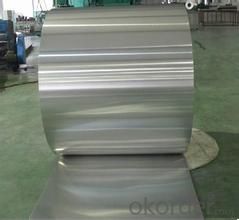

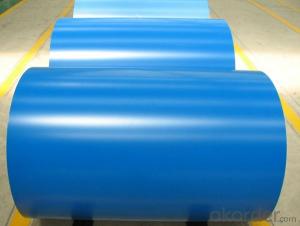

Self-Adhesive Aluminum Foil Sheets - Color Coated Aluminum Coil with 0.018 to 0.50mm (PE/PVDF)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: What are the different methods for perforating aluminum sheets?

- There are several methods for perforating aluminum sheets, including laser cutting, punching, drilling, and waterjet cutting. Each method has its own advantages and is chosen based on factors such as desired hole size, shape, precision, and production volume.

- Q: Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q: What is the width and length of the aluminum sheets?

- The width and length of the aluminum sheets may vary depending on the specific product or manufacturer. It is recommended to refer to the product specifications or contact the manufacturer for accurate measurements.

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum sheets as a roofing material.

- <p>Aluminum sheets for roofing offer several advantages, including durability, resistance to rust and corrosion, lightweight nature, and energy efficiency due to reflective properties. They are also easy to install and maintain, and can be recycled, making them environmentally friendly. However, there are some disadvantages such as being more expensive than some other roofing materials, potential for denting if not properly installed, and noise issues during heavy rain or hail due to their lightweight nature. Additionally, they may require more frequent replacement compared to some other materials.</p>

- Q: Can 101 aluminum sheets be bonded to other materials?

- Yes, 101 aluminum sheets can be bonded to other materials. Aluminum can be bonded using various methods such as adhesive bonding, welding, or mechanical fastening techniques. The choice of bonding method depends on the specific materials being bonded and the desired strength and durability of the bond.

- Q: What is the maximum width available for aluminum sheets?

- The maximum width of aluminum sheets can differ depending on the manufacturer and specific specifications. Typically, aluminum sheets can be found in widths up to 72 inches or 1.83 meters. It should be emphasized that certain manufacturers may provide wider choices for specialized purposes. Furthermore, personalized dimensions can be acquired by placing specific orders, providing more freedom in selecting the desired width.

- Q: What are the different types of finishes available for painted aluminum sheets?

- There are several types of finishes available for painted aluminum sheets, including matte, satin, glossy, metallic, and textured finishes. These finishes provide different levels of sheen, texture, and visual appeal, allowing for a wide range of aesthetic options for various applications.

- Q: Is it possible to use aluminum sheets as a material for exterior wall covering?

- <p>Yes, aluminum sheets can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum is lightweight, which makes it easier to install compared to heavier materials. It also has good thermal properties, helping to insulate buildings. Additionally, aluminum can be coated with various finishes, allowing for a wide range of aesthetic options. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the cladding's performance over time.</p>

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight, durable, and corrosion-resistant material that makes it an ideal choice for various industrial applications, including power distribution panels. Aluminum sheets can withstand high electrical currents while effectively dissipating heat, ensuring the safe and efficient distribution of power. Additionally, aluminum is readily available and cost-effective compared to other materials such as copper. Therefore, aluminum sheets are a suitable choice for manufacturing power distribution panels.

- Q: Can aluminum sheets be painted or coated with different colors?

- Yes, aluminum sheets can be painted or coated with different colors. Aluminum is a versatile material that can be easily painted or coated to achieve various colors and finishes. The process typically involves pre-treating the surface, applying a primer, and then applying the desired paint or coating. This allows for customization and aesthetic enhancement of aluminum sheets in numerous applications.

Send your message to us

Self-Adhesive Aluminum Foil Sheets - Color Coated Aluminum Coil with 0.018 to 0.50mm (PE/PVDF)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords