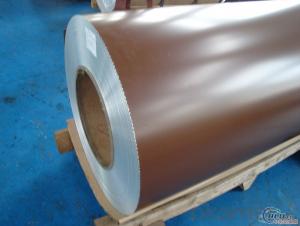

Textured Aluminum Coil - PVDF AA1070 Coated Stucco Embossed Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

supply Mill-finished / coated aluminum sheet/ coil:

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

- Q: Is it safe and practical to use aluminum coils in cooking processes?

- <p>Aluminum coils can be used for cooking, but with certain precautions. They are commonly used in commercial kitchens for their heat conductivity and durability. However, for home cooking, it's important to avoid acidic or alkaline foods, as aluminum can react with them. Additionally, prolonged exposure to heat can cause aluminum to leach into food, which some studies suggest may have health implications. It's advisable to use aluminum cookware with a protective coating or opt for alternative materials like stainless steel or cast iron for health-conscious cooking.</p>

- Q: Can aluminum coils be used for electrical transformers?

- Yes, aluminum coils can be used for electrical transformers. Aluminum is a suitable material for transformer coils due to its high electrical conductivity and lower cost compared to copper. While copper has traditionally been the preferred choice for transformer windings, the use of aluminum has gained popularity in recent years due to its lighter weight and lower price. Aluminum coils are also advantageous in terms of thermal conductivity, as they dissipate heat more efficiently than copper. However, it is important to consider the specific requirements and design considerations of the transformer, as the choice between aluminum and copper coils may depend on factors such as voltage, current, size, and insulation requirements.

- Q: Can aluminum coils be used in the production of aluminum ceilings?

- Aluminum coils possess the ability to be utilized in the creation of aluminum ceilings. These coils are frequently employed in the fabrication of diverse aluminum goods, which encompass aluminum ceilings. Typically, these coils are crafted from top-notch aluminum alloy, which is then processed and molded into coils with the desired dimensions in terms of thickness and width. The coils can be effortlessly cut and molded into the necessary dimensions for the ceiling panels. Furthermore, aluminum is a lightweight, robust, and corrosion-resistant substance, rendering it an optimal choice for ceilings. It is also highly adaptable, allowing for a multitude of finishes and designs to be employed on the aluminum surface, which further amplifies the aesthetic allure of aluminum ceilings. On the whole, aluminum coils play a pivotal role in the production of aluminum ceilings by offering a dependable and enduring material for such applications.

- Q: What is the typical coil width for aluminum coils?

- The typical coil width for aluminum coils can vary, but it is commonly found in the range of 12 inches to 60 inches.

- Q: Can aluminum coils be used in the production of railway tracks?

- No, aluminum coils cannot be used in the production of railway tracks. Railway tracks are typically made of steel due to its strength, durability, and ability to withstand heavy loads and high temperatures. Aluminum, although lightweight, lacks the necessary strength and toughness required for railway track applications.

- Q: Can aluminum coils be used in electrical or electronic applications?

- Aluminum coils find utility in electrical and electronic applications. This material, known for its high conductivity, offers various advantages over alternatives like copper in coil applications. Their lightweight nature renders aluminum coils appropriate for weight-sensitive applications. Furthermore, they possess excellent thermal conductivity, ensuring efficient dissipation of heat. Moreover, aluminum coils exhibit resistance to corrosion, making them durable and suitable for outdoor or high-humidity settings. Nonetheless, it is crucial to acknowledge that aluminum's electrical conductivity is lower than that of copper. Hence, the coil's design and dimensions must be meticulously considered to ensure optimal performance.

- Q: What are the common industry standards for aluminum coil specifications?

- The common industry standards for aluminum coil specifications are established by various organizations such as the Aluminum Association (AA) and the American Society for Testing and Materials (ASTM). These standards ensure uniformity and consistency in the manufacturing and use of aluminum coils across different industries. The Aluminum Association (AA) sets the standards for aluminum alloys and their respective temper designations. The AA standards classify aluminum alloys based on their chemical composition and mechanical properties, allowing manufacturers to produce coils with specific characteristics suitable for different applications. For example, AA 3003 is a commonly used alloy for general-purpose coils, while AA 5052 is often used for marine applications due to its higher corrosion resistance. In addition to alloy classification, the AA also provides guidelines for coil dimensions, tolerances, and surface finishes. These specifications help ensure that aluminum coils meet the required dimensions and quality standards, allowing for easy integration into various manufacturing processes. The American Society for Testing and Materials (ASTM) also plays a significant role in setting standards for aluminum coil specifications. ASTM provides guidelines for various tests and procedures to assess the quality and performance of aluminum coils. These tests include mechanical property testing, such as tensile strength and elongation, as well as tests to evaluate surface finish, corrosion resistance, and dimensional stability. Furthermore, industry-specific standards may exist for certain applications. For example, the automotive industry may have its own set of standards for aluminum coils used in vehicle manufacturing, ensuring compliance with specific performance requirements. Overall, the common industry standards for aluminum coil specifications encompass alloy designation, dimensional tolerances, surface finishes, and mechanical properties. Adhering to these standards ensures consistency, quality, and compatibility across different industries and applications.

- Q: I am concerned about the environment so I collect empty aluminum cans off the street when I walk my dog. Right now I have 3 large garbage bags full of crushed aluminum can. The problem is... some of the cans have dirt on and in them. Some of thoroughly flattened ones may even have small pebbles embedded in them. Will these be accepted at the recycling facility? I'm guessing it doesn't matter because when they melt them any organic materials will burn away and any dirt particles or small pebbles will be separated from the molten aluminum. What do you think?

- The dirt won't be a problem, normally. The pebbles might, but I haven't heard any mention of this being a problem. Add: Aluminum melts at around 960 F, while most rocks won't. By that time, the dried up sugars and cigarette butts will have all burned off. You can melt aluminum in a cast iron frying pan, but I really don't recommend trying that: If a drop of water hits the molten aluminum it'll expand somewhere around 1700 times it's original volume, nearly instantly. This will be like a small bomb going off, and molten aluminum will spray all over. That's quite dangerous, even if you do have protective gear.

- Q: What are the fire-resistant properties of aluminum coils?

- Due to its inherent characteristics as a metal, aluminum exhibits excellent fire-resistant qualities when formed into coils. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum can endure high temperatures without melting, thereby making aluminum coils resistant to fire hazards. Furthermore, unlike certain other metals, aluminum does not produce flammable gases when exposed to fire. This non-combustible attribute prevents the fire from spreading and minimizes the potential for fire-related damages. Additionally, due to its low thermal conductivity, aluminum does not efficiently conduct heat. Consequently, aluminum coils do not facilitate the transfer of heat from one area to another, which aids in containing and controlling the fire's spread. Moreover, aluminum coils frequently undergo a protective coating process to enhance their fire resistance. These coatings, composed of materials like polyvinylidene fluoride (PVDF) or polyester, create an additional barrier against fire and heat. Engineered to withstand extreme temperatures while maintaining their integrity, these coatings further bolster the fire-resistant qualities of aluminum coils. In summary, aluminum coils possess exceptional fire-resistant characteristics owing to their high melting point, non-combustible nature, low thermal conductivity, and protective coatings. These attributes make aluminum coils a dependable choice for applications where fire safety is paramount, such as in building construction, electrical wiring, and transportation industries.

- Q: How are aluminum coils used in the production of battery enclosures?

- Aluminum coils are used in the production of battery enclosures as they provide a lightweight and durable material that can be easily molded and shaped to form the enclosure. The coils are typically processed and formed into specific shapes using a combination of heating, rolling, and cutting techniques. This allows for the creation of seamless and tightly sealed enclosures that can protect the batteries from external elements and provide efficient heat dissipation.

Send your message to us

Textured Aluminum Coil - PVDF AA1070 Coated Stucco Embossed Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords