Geotextile Separation Membrane for Reinforcement and Drainage - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Filtration:

It can be the filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

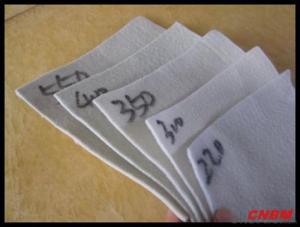

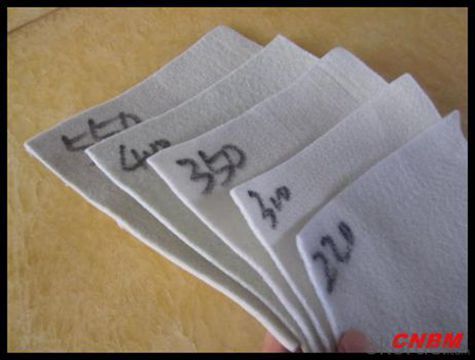

A: Yes, please check the pictures:

- Q: What are the regulations for geotextiles in construction projects?

- The regulations for geotextiles in construction projects vary depending on the country and specific project requirements. However, in general, geotextiles used in construction projects must meet certain standards and guidelines to ensure their quality and performance. These may include specifications for the physical properties, such as strength and durability, as well as requirements for permeability and filtration. Additionally, some regulatory bodies may have specific testing and certification processes that geotextiles must undergo before they can be used in construction projects. It is important for project managers and engineers to consult local building codes and regulations to ensure compliance with the specific requirements in their region.

- Q: Can geotextiles be used in rockfall protection works?

- Yes, geotextiles can be used in rockfall protection works. Geotextiles are often used as a form of erosion control and soil stabilization, and they can also be effective in mitigating rockfall hazards. By installing geotextiles on slopes or embankments, they can help to absorb the impact of falling rocks, prevent the rocks from gaining momentum, and reduce the risk of damage or injury caused by rockfall.

- Q: What are the key factors affecting the durability of geotextiles?

- The key factors affecting the durability of geotextiles include the quality of the materials used, exposure to environmental conditions such as UV radiation and moisture, the level of mechanical stress and loading, and the installation and maintenance practices.

- Q: Are geotextiles commonly used in agriculture?

- Yes, geotextiles are commonly used in agriculture. Geotextiles have multiple applications in the agricultural industry, including soil stabilization, erosion control, weed suppression, and drainage management. They help improve soil quality, reduce erosion, and enhance crop growth, making them a valuable tool for many farmers and agricultural practices.

- Q: Can geotextiles be used in underground storage tank installations?

- Yes, geotextiles can be used in underground storage tank installations. Geotextiles are commonly used as a protective barrier between the tank and the surrounding soil, providing filtration and separation functions. They can help prevent soil erosion, control groundwater flow, and provide additional stability to the tank system.

- Q: Can geotextiles be used in wastewater treatment systems?

- Yes, geotextiles can be used in wastewater treatment systems. Geotextiles are commonly used for filtration, separation, and drainage purposes in various engineering applications, including wastewater treatment. They can be used as a barrier to prevent fine particles from clogging drainage systems, as a filter to remove solid contaminants from wastewater, and as a reinforcement material in the construction of wastewater treatment structures.

- Q: What are the considerations for geotextile selection in landfill projects?

- The considerations for geotextile selection in landfill projects include factors such as the required strength and durability of the geotextile, its ability to resist punctures and tearing, its compatibility with the waste material, and its resistance to chemical degradation. Other factors to consider include the geotextile's permeability, its ability to retain soil particles while allowing for proper drainage, and its cost-effectiveness. Additionally, the geotextile should be selected based on its compliance with regulatory requirements and standards for landfill construction.

- Q: Geotextile puncture test standard

- Staple stitch filament piercing filament woven weaving

- Q: Are geotextiles commonly used in mining tailings management?

- Yes, geotextiles are commonly used in mining tailings management.

- Q: Unit of the quality of 400 geotextile piercing strong is generally how much? Hurry more

- First, geotextile polyester staple fiber geotextile (PET) and polyester filament geotextile two. Two kinds of geotextile anti-puncture strong (should be CBR burst strong) different. Polyester staple geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester staple geotextile CBR burst strength ≥ 2.1KN. Polyester filament geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester filament geotextile CBR burst strength ≥ 39KN. 400g GB polyester staple geotextile longitudinal and horizontal tear strength ≥ 0.33KN, 400g GB polyester filament geotextile longitudinal and horizontal tear strength ≥ 0.56KN.

Send your message to us

Geotextile Separation Membrane for Reinforcement and Drainage - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords