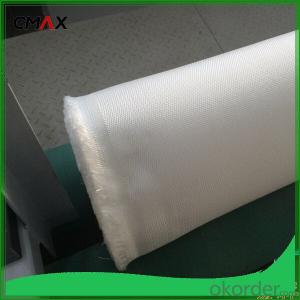

Woven Geotextile Fabric for Sale - Nutrition Geotextile Mat Reinforcement Geotextile Factory Supply Direct

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nutrition geotextile in water environmental engineering .

Specification:

Anti-uv

Anti-aging

eco-freindly

with grass seed attached in bag

easy for construction and move

Product Feature:

1. Simple and fast construction

2. Achieve the greening effect quickly after construction

3. Due to the grass and composite fiber fabrics become into one integration, so it has the ability of certain degree of flow resistance for the water rising before the grass survive.

4. Composite fiber fabric is a continuous structure from slope top to slope toe, both ends are fixed, has high water flow resistance.

Technical Specification

5.0 m length and 1.05 m width. Reverse side all used filter material. Grass seeds: Bermuda grass (warm season grass), Bahia grass (warm season grass), Kentucky bluegrass (cold season grass), Tall fescue grass (cold season grass), Red fescue grass (cold season grass). Plant height: 0.1 ~ 0.5 m.

| NO. | Items | Specification | Notes | |||

| 1 | Total unit area weight g/sq.m | ≥380 | ||||

| 2 | dimension | width m | 1.0~2.0 | |||

| length m | as per user’s request | |||||

| 3 | Composite fiber fabrics | Material | Polyester Fiber | High strength PET | ||

| Unit area weight g/sq.m | ≥160 | |||||

| Mesh dimension mm | 8×8 | |||||

| Extension strengh kn/m | ≥11 | MD & CD | ||||

| 4 | Filtra layer | Material | Polyester non woven geotextile | |||

| Unit area weight g/sq.m | ≥40 | |||||

| 5 | Grass seeds, Fertilizer | Type | According to actual situation choose 3~5 grass seeds | |||

| Plant height m | 0.1~0.3 | |||||

| 6 | Fiber layer | Material | wood pulp cellulose | |||

| Unit areaweight g/sq.m | ≥15 | |||||

| 7 | flow resistance | ≥4 | not allow appear scour, suction and blanket turn-over etc. damage phenomenon | |||

| M/s | ||||||

| 8 | Anti-UV strengh conservation rate % | 65~80 | 3000hrs Continuously exposure 3000hrs | |||

| 9 | Supporting spare parts | ABS fastening nail | Material | ABS Resin | Fixed between two blankets by length direction | |

| Fiber diameter mm | 35 | |||||

| Nail length mm | 325 | |||||

| Lnail | Material | Steel wire (content 10% zinc-aluminium alloy) | Used to fix single blanket | |||

| Fiber diameter mm | 4 | |||||

| Nail length mm | 200 | |||||

| ABS connecting nail | Material | ABS Resin | Used in the slope between the two blankets ( width direction) | |||

| Nail length mm | 38 | |||||

| Connecting fiber | Material | High strength Polypropylene | Used in the slope between the two blankets ( width direction) | |||

| Length mm | Cut as per request | |||||

APPLICATION:

Generally laid on the river channel, slope protection etc. slope revetment projects, to control the water erosion, soil loss, meantime can reach the effect of slope ecological restoration and landscape greening, making river back to natural.

- Q: Is the current tunnel construction, modular waterproof board (geotextile) is available?

- This is a new type of combination of anti-storage, drainage and drainage structure: the bottom of the polymer thermoplastic waterproof sheet, the surface of the sheet was plum-shaped hollow conical arrangement, the middle is unique by the two layers of staggered Composed of TDV three-dimensional geonet, the upper non-woven geotextile, the combination of new products in the use of the process to maintain a considerable thickness, load load increases, can provide a high conductivity.

- Q: What are the specifications for geotextiles in sediment control projects?

- The specifications for geotextiles in sediment control projects typically include factors such as the material type, weight, permeability, and strength. They should be made of durable materials that can withstand environmental conditions and retain sediment effectively. The weight of the geotextile is usually specified to ensure proper retention of sediment particles. Permeability is an important factor as it allows water to pass through while retaining sediment. Lastly, the strength of the geotextile should be sufficient to withstand installation and potential stress from soil erosion.

- Q: Can geotextiles be used for separation of different soil layers?

- Yes, geotextiles can be used for the separation of different soil layers. Geotextiles act as a barrier between different soil layers, preventing their mixing and maintaining their individual characteristics. This helps to enhance soil stability and prevent the loss of fine particles, ensuring the long-term performance of structures built on or with different soil layers.

- Q: What is the meaning of the process equipment and equipment for producing geotextiles?

- What is the meaning of the process equipment and equipment for producing geotextiles?

- Q: Textile geotextile lap length how much

- Lap width is generally 10-15cm

- Q: Can geotextiles be used in geocomposite applications?

- Yes, geotextiles can be used in geocomposite applications. Geocomposites are multi-layered materials that combine different geosynthetic products, such as geotextiles, geogrids, and geonets. Geotextiles are often used as a component in geocomposites to provide filtration, separation, and reinforcement functions.

- Q: Are geotextiles suitable for use in reservoir lining?

- Yes, geotextiles are suitable for use in reservoir lining. They are a cost-effective and efficient solution for preventing soil erosion, enhancing filtration, and providing stability to the reservoir's lining. Geotextiles can effectively separate different soil layers, improve drainage, and prevent the migration of fine particles, which makes them ideal for lining reservoirs and ensuring their long-term integrity and functionality.

- Q: What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by weaving continuous individual yarns together, creating a strong and durable fabric. On the other hand, non-woven geotextiles are made by bonding or felting together synthetic fibers, resulting in a fabric that is not as strong or durable as woven geotextiles. Woven geotextiles provide higher tensile strength, better filtration, and are typically used in applications that require greater longevity and stability. Non-woven geotextiles, while less durable, are often used for filtration and separation purposes due to their high water flow rates and ability to retain fine particles.

- Q: Road overhaul of the original concrete pavement after shaving asphalt, anti-cracking is geotextile or geogrid more

- Generally used in the geotextile, generally used in soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green belt

- Q: Can geotextiles be used in the protection of groundwater sources?

- Yes, geotextiles can be used in the protection of groundwater sources. Geotextiles are permeable fabrics that can effectively filter out impurities and prevent soil erosion. By installing geotextiles in areas where groundwater sources are vulnerable to contamination or excessive sedimentation, they can act as a barrier, allowing water to pass through while trapping pollutants and preventing them from reaching the groundwater. This helps to maintain the quality and purity of groundwater sources, ensuring their long-term protection.

Send your message to us

Woven Geotextile Fabric for Sale - Nutrition Geotextile Mat Reinforcement Geotextile Factory Supply Direct

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords